High-concentration tailing pulp continuous sampling system

A sampling system and high-concentration technology, applied in the fields of metallurgy and mine beneficiation, can solve problems such as difficult installation, repair and maintenance operations, small gradient of artesian pipelines, and heavy workload, and achieve novel design ideas, good performance, and low production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

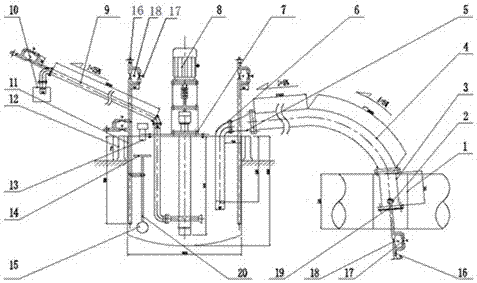

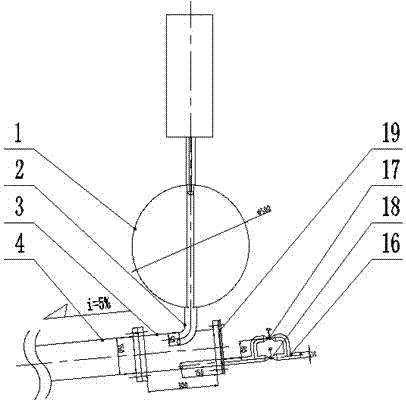

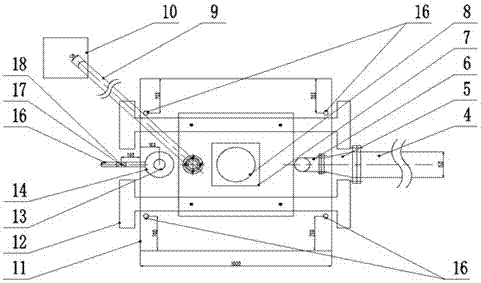

[0018] Provide the specific embodiment of the present invention below in conjunction with accompanying drawing as follows:

[0019] like figure 1 , figure 2 , image 3 As shown, a continuous sampling system for high-concentration tailings slurry of the present invention is mainly composed of a sampler 1, a sampling elbow 2, a φ150 steel pipe nipple 3, a φ150 PE drainage pipe 4, an eccentric reducing joint 5, and a φ80 steel pipe. Slurry pipeline 6, submerged slurry pump 7, adjustable speed motor 8, φ50 PE sizing pipeline 9, online grade analysis system 10, dilution buffer tank 11, submerged slurry pump fixing bracket 12, laser level gauge 13, PE Reflecting plate 14, floating ball 15, high-pressure flushing pipe 16, manual flushing valve 17, electromagnetic flushing valve 18, blocking plate 19, and floating rod 20;

[0020]Among them, the sampling and drainage system for high-concentration tailings slurry is composed of sampler 1, sampling elbow 2, φ150 steel pipe nipple 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com