Perovskite type quantum dot film

A perovskite-type, quantum dot film technology, applied in coatings, instruments, optics, etc., can solve problems such as high production costs, edge quantum dot failure, quantum dot luminous efficiency quenching, etc., achieve long service life, prevent The effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

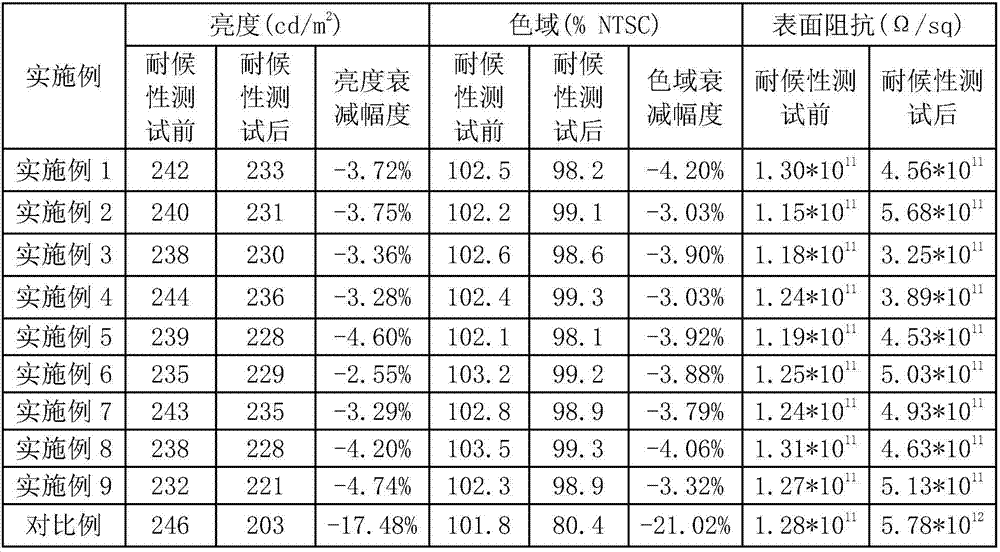

Examples

Embodiment 1

[0035] (1) Quantum dot layer coating solution is prepared according to the formula of table 1, wherein polymer component and ratio are polyvinylidene fluoride: polyvinyl acetate=1:1;

[0036] (2) Coating the quantum dot layer coating solution on the transparent substrate, heating and curing at 70°C, and forming a film for later use;

[0037] (3) coating a barrier layer on the quantum dot layer obtained in the previous step, the material of the barrier layer is a silicon oxide compound (SiO x ), with a thickness of 0.5 μm;

[0038] (4) Finally, a layer of anti-adhesive layer is coated on the barrier layer. The anti-adhesive layer is coated with polystyrene particles, polyurethane acrylic resin, and ionic liquid antistatic agent, and the particle size of the diffusion particles is 5 μm.

[0039] Table 1 Embodiment 1 Quantum dot layer coating solution formula

[0040] Recipe 1

[0041] In this embodiment, the other side of the transparent substrate is coated with a di...

Embodiment 2

[0043] (1) Quantum dot layer coating solution is prepared according to the formula of table 2, wherein high molecular polymer component and ratio are polyvinylidene fluoride: polyvinyl acetate=1:2;

[0044] (2) Coating the quantum dot layer coating solution on the transparent substrate, heating and curing at 70°C, and forming a film for later use;

[0045] (3) coating a barrier layer on the quantum dot layer obtained in the previous step, the material of the barrier layer is a silicon oxide compound (SiO x ), with a thickness of 0.6 μm;

[0046] (4) Finally, a layer of anti-adhesive layer is coated on the barrier layer. The anti-adhesive layer is coated with polyacrylate particles, polyurethane acrylic resin, and ionic liquid antistatic agent, and the particle size of the diffusion particles is 6 μm.

[0047] Table 2 Embodiment 2 Quantum dot layer coating solution formula

[0048] Recipe 2

[0049] In this embodiment, the other side of the transparent substrate is ...

Embodiment 3

[0051] (1) Quantum dot layer coating solution is prepared according to the formula of table 3, wherein high molecular polymer component and ratio are polyvinylidene fluoride: polyvinyl acetate=1:3;

[0052] (2) Coating the quantum dot layer coating solution on the transparent substrate, heating and curing at 70°C, and forming a film for later use;

[0053] (3) coating a barrier layer on the quantum dot layer obtained in the previous step, the material of the barrier layer is a silicon oxide compound (SiO x ), with a thickness of 1 μm;

[0054] (4) Finally, a layer of anti-adhesive layer is coated on the barrier layer. The anti-adhesive layer is coated with polymethacrylate particles, polyurethane acrylic resin, and ionic liquid antistatic agent. The particle size of the diffusion particles is 10 μm.

[0055] Table 3 Embodiment 3 Quantum dot layer coating solution formula

[0056] Recipe 3

[0057] In this embodiment, the other side of the transparent substrate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com