Color sorting method for copper and aluminum foil particles of battery cell broken product of power battery

A power battery and particle technology, applied in the field of image processing, can solve problems such as the inability to effectively and accurately separate the copper and aluminum foil particles of the broken product of the power battery cell, and achieve the effect of simple software and hardware environment, improved accuracy, and simple and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

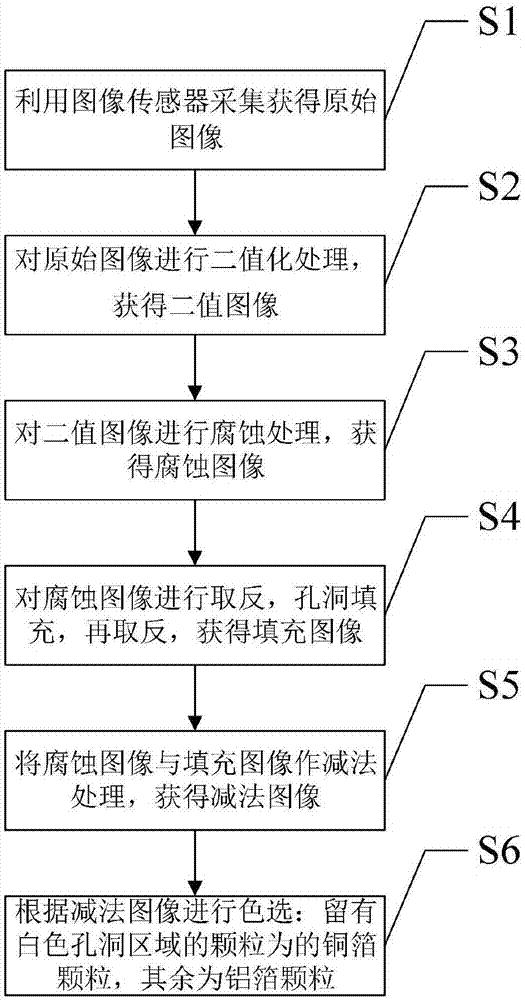

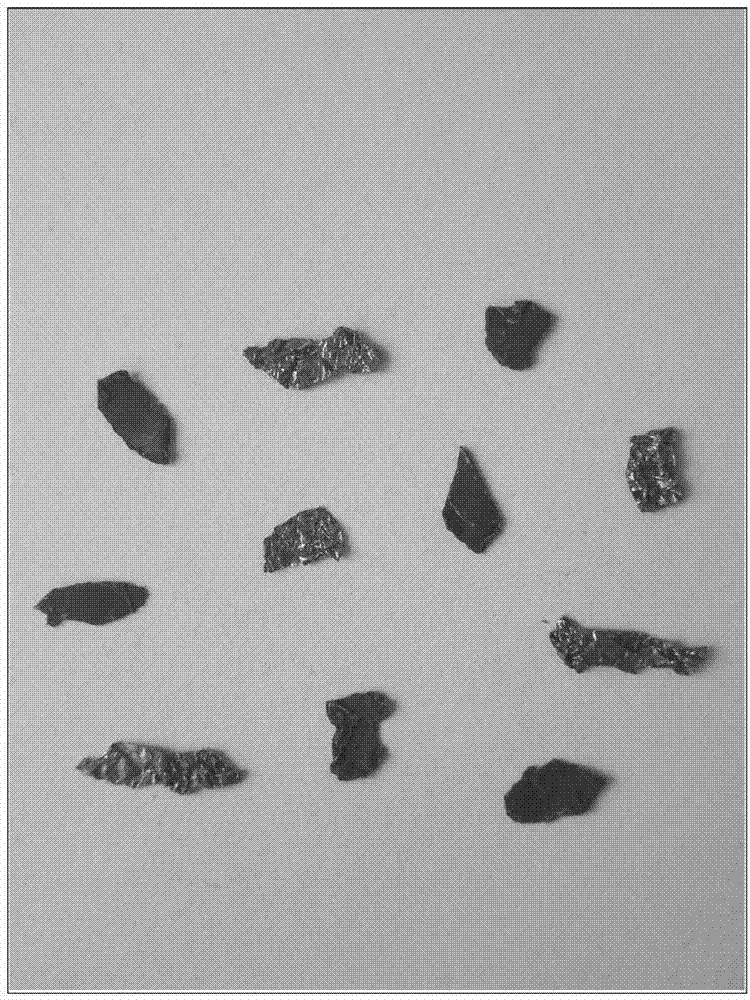

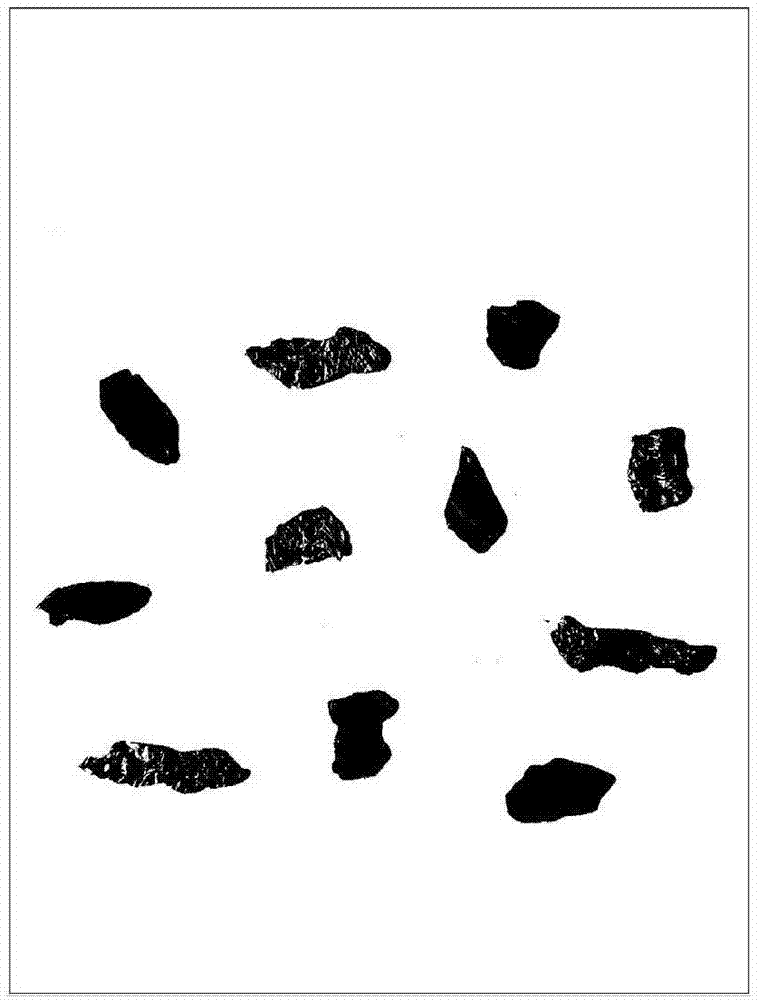

[0026] This embodiment provides a color sorting method for the copper and aluminum foil particles of the crushed product of the power battery cell, and its applicable object—the copper and aluminum foil particles of the crushed product of the power battery cell can be obtained by the following method: crushing the lithium iron phosphate power battery cell The crushed copper-aluminum foil particles obtained after the product is sieved and winnowed to remove powder and plastic diaphragms, the particle diameter of the copper-aluminum foil particles ranges from 3 to 12 mm. Because the electrode material graphite powder on the copper foil is completely dissociated after crushing, but the electrode material on the aluminum foil is basically not dissociated, which causes a large difference in the color and shape texture characteristics of the crushed copper and aluminum foil particles. The selected method realizes the separation of copper and aluminum foil particles.

[0027] The sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com