Melting-casting sand mold material and preparation method thereof

A technology of sand mold and brick sand, which is applied in the field of melting and casting sand mold materials and its preparation, can solve the problems of low utilization rate, pollution of the environment, waste of resources, etc., and achieve the effects of thin erosion layer, reduction of environmental load, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

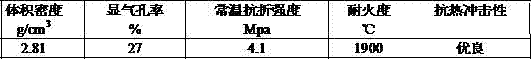

[0021] Expressed in weight percentage, the raw materials are: 15% of recycled magnesia-spinel brick sand of 5~3mm, 45% of recycled magnesia-spinel brick sand of 3~1mm, and recycled magnesia-spinel brick sand -The weight composition of spinel brick sand is: MgO 82.5%, MgO+Al 2 o 3 91.9%, Fe 2 o 3 0.72%, CaO 1.03%, 40% of magnesia ≤ 1mm, the MgO content of magnesia is 95.3%; The ratio of 7 is added to the water glass solution, and it is used after standing for 24 hours. Modified water glass modulus is 2.9. Weigh the above-mentioned raw materials according to the required ratio, mix the materials in the mixer for 1 minute, add 5% by weight of modified water glass, continue to stir for 3 minutes, and carry out manual or mechanical molding according to the size of the template after discharging. Dry at ℃ for 8 hours, and form molds as required after drying. Its performance indicators are shown in the following table 1:

[0022]

Embodiment 2

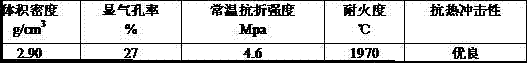

[0024] Expressed in weight percentage, the raw materials are: 10% of recycled magnesite-spinel brick sand of 5~3mm, 45% of recycled magnesite-spinel brick sand of 3~1mm, recycled magnesium of ≤1mm Periclase-spinel brick sand 20%, the weight composition of recycled magnesite-spinel brick sand is: MgO 80.4%, MgO+Al 2 o 3 88.9%, Fe 2 o 3 0.76%, CaO 1.25%, magnesia 20%≤1mm, the MgO content of magnesia is 95.7%; The addition amount of modified water glass is 5%, and modified water glass adopts polyacrylamide under normal temperature according to weight ratio 1: The ratio of 10 is added to the water glass solution, and it is used after standing for 24 hours. Modified water glass modulus is 2.7. Weigh the above raw materials according to the required ratio, mix the materials in the mixer for 2 minutes, add 7% weight ratio of modified water glass, continue to stir for 3 minutes, and carry out manual or mechanical molding according to the size of the template after discharging. ...

Embodiment 3

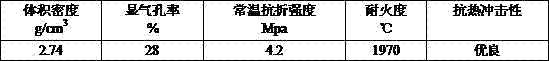

[0026] Expressed in weight percentage, the raw materials are: 12% of recycled magnesia periclase-spinel brick sand of 5~3mm, 55% of recycled magnesia periclase-spinel brick sand of 3~1mm, recycled magnesium of ≤1mm Periclase-spinel brick sand 13%, the weight composition of recycled magnesite-spinel brick sand is: MgO 82.4%, MgO+Al 2 o 3 93.7%, Fe 2 o 3 0.57%, CaO 1.05%, magnesia 20%≤1mm, the MgO content of magnesia is 92.7%; The addition amount of modified water glass is 4%, and modified water glass adopts polyacrylamide under normal temperature according to weight ratio 1: The ratio of 8 is added to the water glass solution, and it is used after standing for 24 hours. Modified water glass modulus is 2.8. Weigh the above raw materials according to the required ratio, mix the materials in the mixer for 2 minutes, add 4% weight ratio of modified water glass, continue to stir for 2 minutes, and carry out manual or mechanical molding according to the size of the template aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com