A kind of carbon fiber reinforced PET composition and preparation method thereof

A technology of carbon fiber and composition, which is applied in the field of polymer composite materials, can solve the problems affecting the appearance and performance of compression-resistant parts, and achieve the effects of improving flow performance, improving compression resistance, and increasing interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

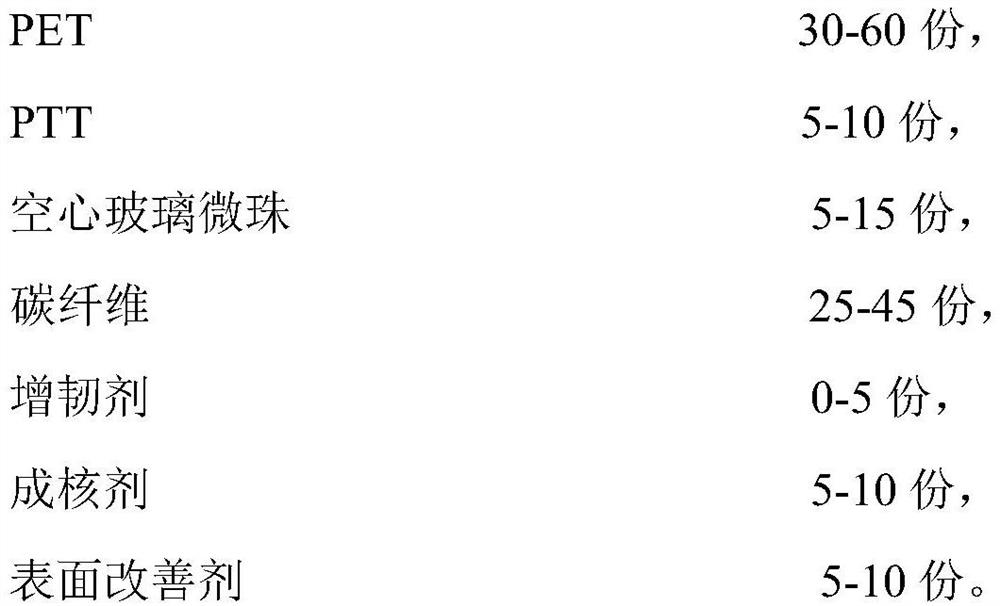

Method used

Image

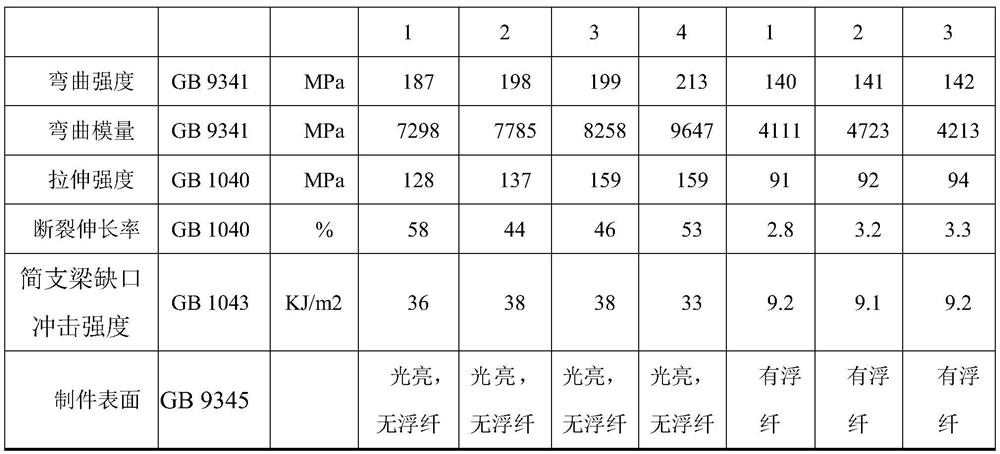

Examples

Embodiment 1

[0033] (1) Dry PET at 110°C for 4 hours; PTT at 110°C for 4 hours;

[0034] (2) take by weighing dry 60 parts of PET, 5 parts of PTT, 25 parts of carbon fiber, 5 parts of hollow glass microspheres, 5 parts of sodium benzoate, 5 parts of surface improving agent (ethylene bis fatty acid amide (TAF) and The weight ratio of silicone oil is 1:1);

[0035] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-min;

[0036] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0037] (5) The material is melt-extruded and granulated by a twin-screw extruder to obtain a glass fiber reinforced PET composition;

[0038] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 230°C, the temperature of the second zone is 245°C, the temperature of the third zone is 255°C, the temperature of the fourth zone is 265°C, the temperatur...

Embodiment 2

[0040] (1) Dry PET at 120°C for 4 hours; PTT at 120°C for 4 hours;

[0041] (2) Take by weighing 40 parts of dry PET, 10 parts of PTT, 30 parts of carbon fiber, 15 parts of hollow glass microspheres, 5 parts of toughening agent maleic anhydride grafted ethylene-octene copolymer, 5 parts of Sodium benzoate, 5 parts of surface improving agent (ethylene bis fatty acid amide (TAF): silicone oil weight ratio is 1:1);

[0042] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-5min;

[0043] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0044] (5) The material is melt-extruded and granulated by a twin-screw extruder to obtain a glass fiber reinforced PET composition;

[0045] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 220°C, the temperature of the second zone is 225°C, the temperature of the third z...

Embodiment 3

[0047] (1) Dry PET at 140°C for 5 hours; PTT at 120°C for 5 hours;

[0048] (2) take by weighing dry 40 parts of PET, 6 parts of PTT, 10 parts of hollow glass microspheres, 35 parts of carbon fiber, 3 parts of toughening agent ethylene-methyl acrylate copolymer, 5 parts of sodium benzoate, 5 parts Parts of surface improving agent (ethylene bis fatty acid amide (TAF): silicone oil weight ratio is 1:1);

[0049] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-5min;

[0050] (4) Then the above-mentioned uniformly mixed material is added to the feeding port of the twin-screw extruder;

[0051] (5) The material is melt-extruded and granulated by a twin-screw extruder to obtain a glass fiber reinforced PET composition;

[0052] The processing technology of the twin-screw extruder is as follows: the temperature of the first zone of the twin-screw extruder is 240°C, the temperature of the second zone is 255°C, the temperature of the third zone is 265°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com