Conjugate two-component solvent-free electrospinning nanofiber and preparation method and device thereof

A micro-nano fiber and two-component technology, applied in the direction of electrospinning, fiber treatment, fiber chemical characteristics, etc., can solve the problems of electromagnetic interference, affecting the smooth spinning, complicated heating devices, etc., to achieve high raw material utilization rate, The preparation method is simple and the experimental conditions are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

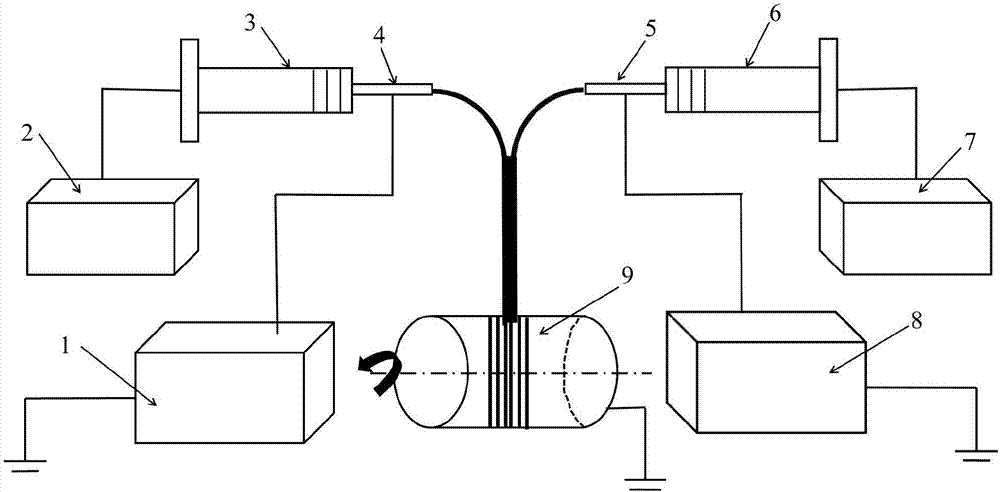

[0027] Such as figure 1As shown, a conjugated two-component solvent-free electrospinning device, the electrospinning device includes two liquid storage mechanisms, each of the liquid storage mechanisms is connected to a spinning nozzle, and the liquid storage mechanisms are connected to The driving mechanism that drives the liquid into the spinning nozzle. The nozzles of the two spinning nozzles are arranged horizontally. The nozzles of the two spinning nozzles are opposite to each other. One of the spinning nozzles is electrically connected to the positive pole of the positive high-voltage power supply 1, and the negative pole of the positive high-voltage power supply 1 is grounded. , the other spinning nozzle is electrically connected to the negative pole of the negative high-voltage power supply 8, the positive pole of the negative high-voltage power supply 8 is grounded, and a grounded collector is arranged directly below the two spinning nozzles; the liquid storage mechani...

Embodiment 3

[0033] The method for preparing micro-nano fibers using the device of Example 1 may further comprise the steps:

[0034] (1) Configure the spinning precursor solution: add 50 parts of octyl acrylate, 15 parts of ethylene glycol dimethacrylate, 10 parts of methacrylic acid, 0.02 parts of hydroquinone, and 264-antioxidant in the reaction kettle 0.02 parts, 3 parts of ethylene glycol, stirred for about 0.5 hours, added 15 parts of ABS resin, 3 parts of cumene hydrogen peroxide, and continued to stir for about 2 hours to obtain the oxidized component spinning precursor; in another reaction kettle Add 52 parts of octyl acrylate, 8 parts of ethylene glycol dimethacrylate, 10 parts of methacrylic acid, 0.01 part of hydroquinone, stir for about 0.5 hours, add 15 parts of nitrile rubber, 8 parts of tetramethylthiourea parts, continue to stir for about 2 hours to obtain the reducing component spinning precursor solution; the parts are the parts by mass of the raw materials;

[0035] (2...

Embodiment 4

[0037] The method for preparing micro-nano fibers using the device of Example 1 may further comprise the steps:

[0038] (1) Configure the spinning precursor solution: add 50 parts of isobornyl methacrylate, 15 parts of ethylene glycol dimethacrylate, 10 parts of methacrylic acid, 0.02 parts of hydroquinone, 264- 0.02 part of antioxidant, 3 parts of ethylene glycol, stirred for about 0.5 hours, added 15 parts of nitrile rubber, 3 parts of cumene hydrogen peroxide, and continued to stir for about 2 hours to obtain the oxidized component spinning precursor solution. Add 52 parts of isobornyl methacrylate, 8 parts of ethylene glycol dimethacrylate, 10 parts of methacrylic acid, 0.01 part of hydroquinone into a reaction kettle in sequence, stir for about 0.5 hours, add 15 parts of nitrile rubber , 8 parts of N,N-dimethylaniline, and continued to stir for about 2 hours to obtain the reducing component spinning precursor solution; the parts mentioned are the mass parts of the raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com