Sampling and sample preparation system and sampling and sample preparation method

A sample preparation system and carbon dioxide technology, which are applied in separation methods, chemical instruments and methods, preparation of samples for testing, etc., can solve the difficulty in formulating subsidy standards and subsidy policies for biomass co-firing power generation, restricting co-firing power generation technology and its Market development, lack of biomass mixing and other issues, to achieve the effect of improving sampling efficiency, reducing costs, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

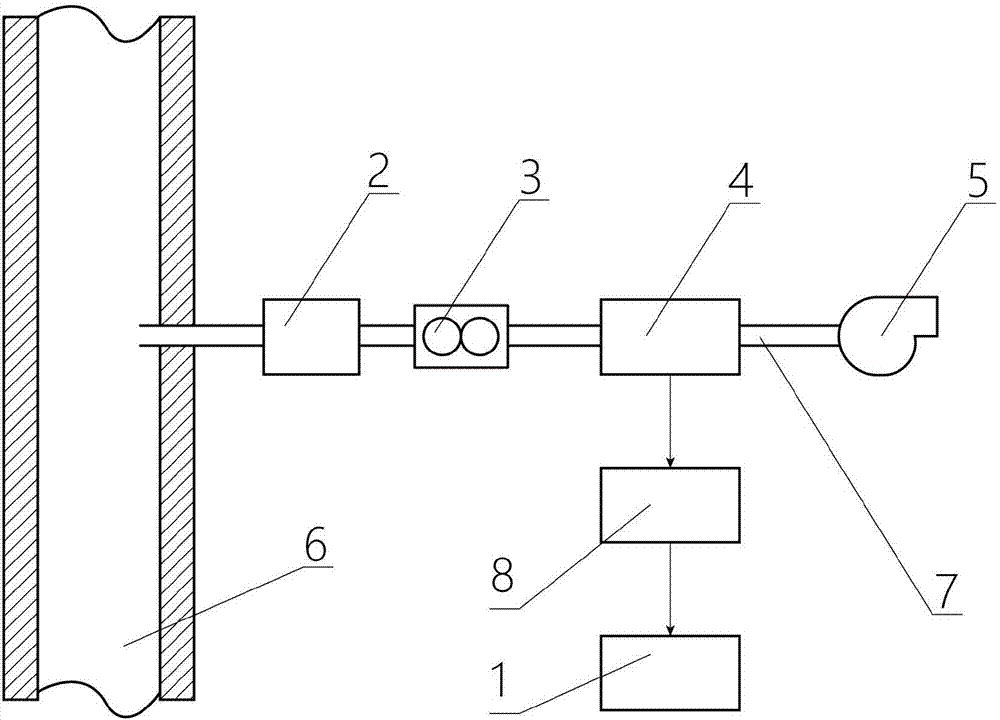

[0089] The first embodiment of the present invention provides a sample preparation system, which is set in a coal-mixed biomass power station, see figure 1 Shown, including:

[0090] The sampling pipe 7 connected to the boiler flue 6 of the coal-mixed biomass power plant is arranged in sequence from the end close to the boiler flue 6 to the end far away from the boiler flue 6 of the sampling pipe 7:

[0091] Filter device 2, mass flow controller 3, carbon dioxide trap 4 and air extraction device 5.

[0092] The sampling system also includes a carbon dioxide transfer device 8 and a carbon-14 test device 1. The carbon dioxide transfer device 8 is used to transfer the carbon dioxide in the carbon dioxide trap 4 to the carbon-14 test device 1 and the carbon-14 test device 1 is used to test carbon dioxide. Carbon-14 measurement.

[0093] figure 1 The arrow in indicates the direction of carbon dioxide transfer.

[0094] Among them, the carbon dioxide trap 4 mentioned in this embodiment may b...

Embodiment approach 2

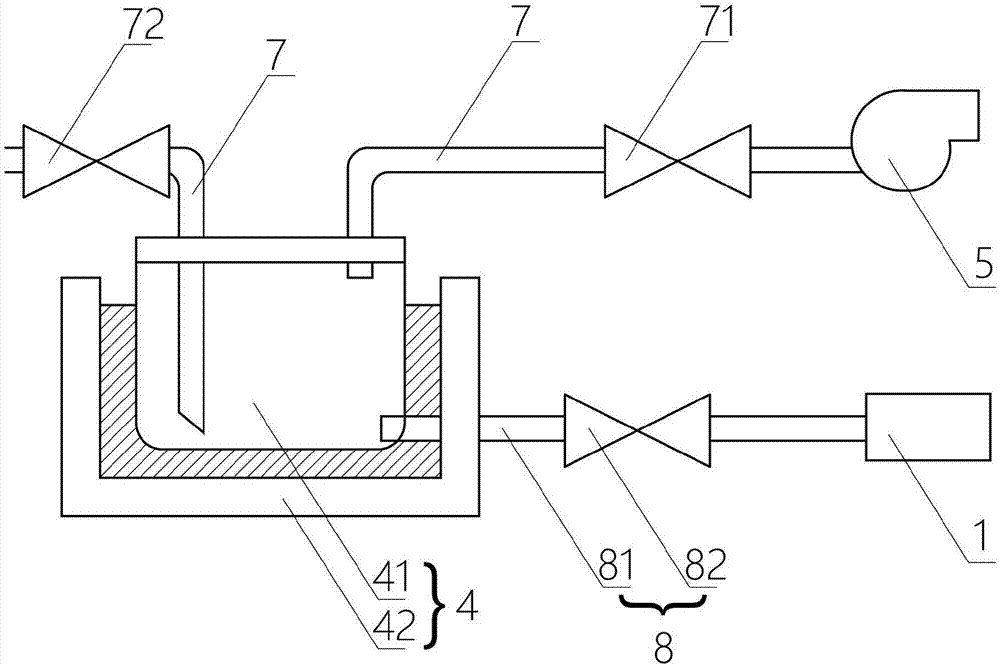

[0127] The second embodiment of the present invention provides a sampling and sample preparation system. The second embodiment is a further improvement of the sampling and sample preparation system of the first embodiment. The main improvement is that in the second embodiment of the present invention , See image 3 As shown, carbon dioxide trap 4 includes:

[0128] A capture container 41 for fixing carbon dioxide and a temperature adjustment device 42 for adjusting the temperature of the capture container 41.

[0129] An emptying valve 71 is installed on the sampling pipe 7 where the air extraction device 5 and the carbon dioxide trap 4 are connected, and the sampling pipe 7 is equipped with a front-end valve at the position connecting the mass flow controller 3 and the carbon dioxide trap 4 Valve 72.

[0130] The transfer device includes a transfer pipe 81 connected to the carbon dioxide trap 4 at one end, and the other end of the transfer pipe 81 is connected to the carbon-14 test...

Embodiment approach 3

[0144] The third embodiment of the present invention provides a sampling and sample preparation system. The third embodiment is an improvement of the second embodiment of the sampling and sample preparation system. The main improvement lies in that, in the third embodiment of the present invention, See Figure 5 As shown, the transfer pipe 81 is sequentially arranged from the part close to the carbon dioxide trap 4 to the part far away from the carbon dioxide trap 4:

[0145] The gas compressor 83, the pressure vessel 84, the second transfer valve 85 and the transfer pump 86.

[0146] The first transfer valve 82 is arranged between the gas compressor 83 and the carbon dioxide trap 4;

[0147] The gas compressor 83 is used to compress carbon dioxide into a liquid or supercritical state in the pressure vessel 84.

[0148] The transfer pump 86 is used to transfer the carbon dioxide in the pressure vessel 84 to the carbon-14 testing device 1.

[0149] This embodiment also provides a sampli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com