NXN fine pitch array collimator

A technology of collimator and optical fiber array, applied in the field of optical communication, can solve the problems of difficult commercialization, large collimator interval, and high raw material cost, and achieve the goal of ensuring direction consistency, high collimation parallelism, and low raw material cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

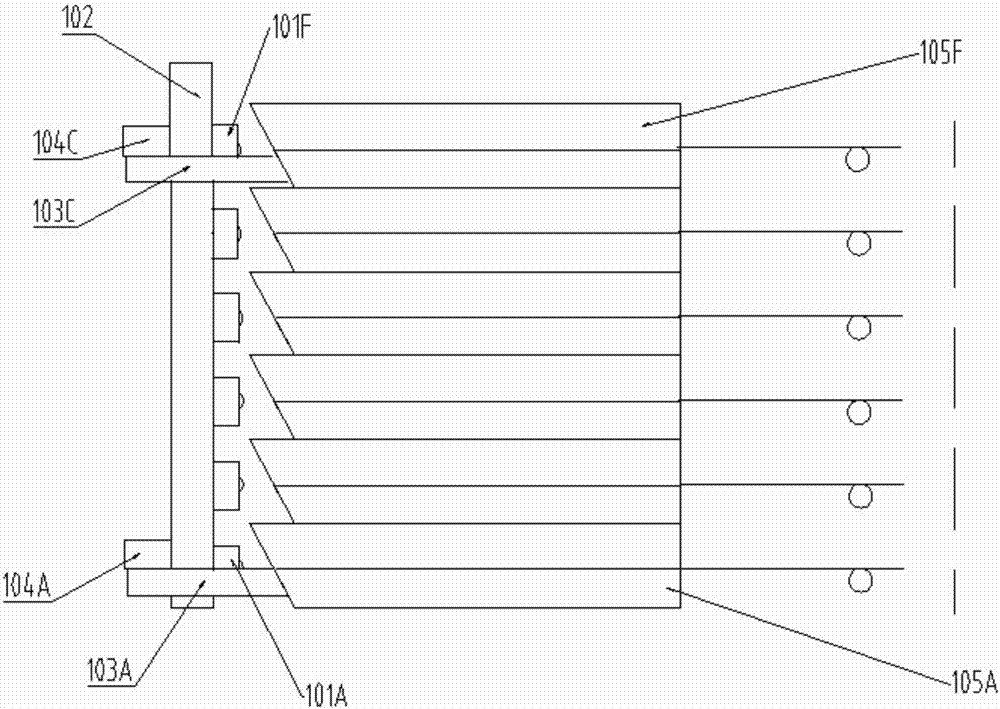

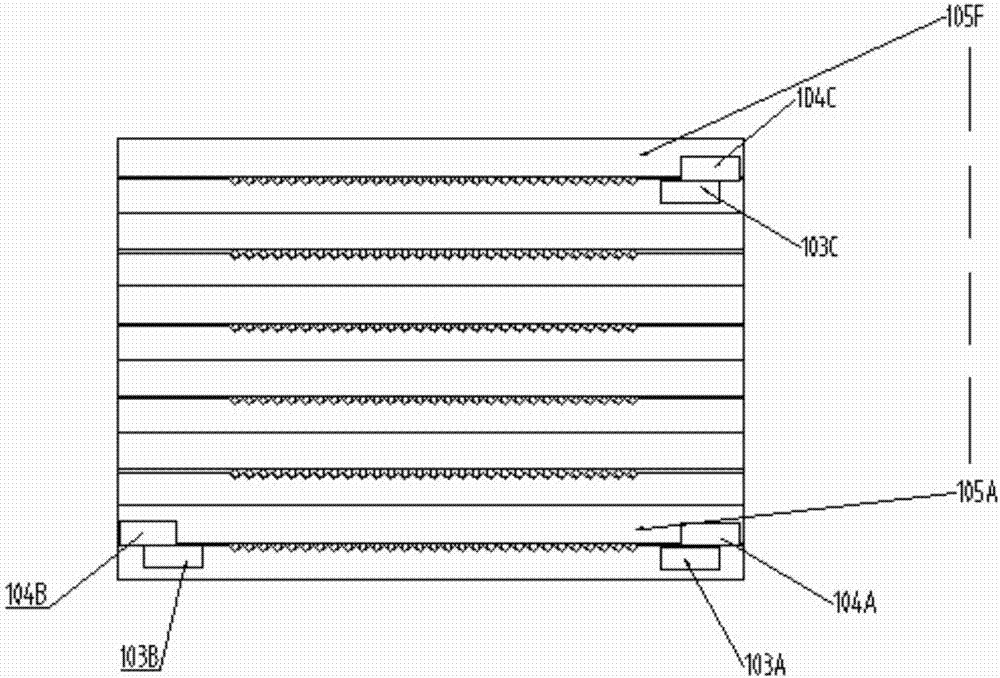

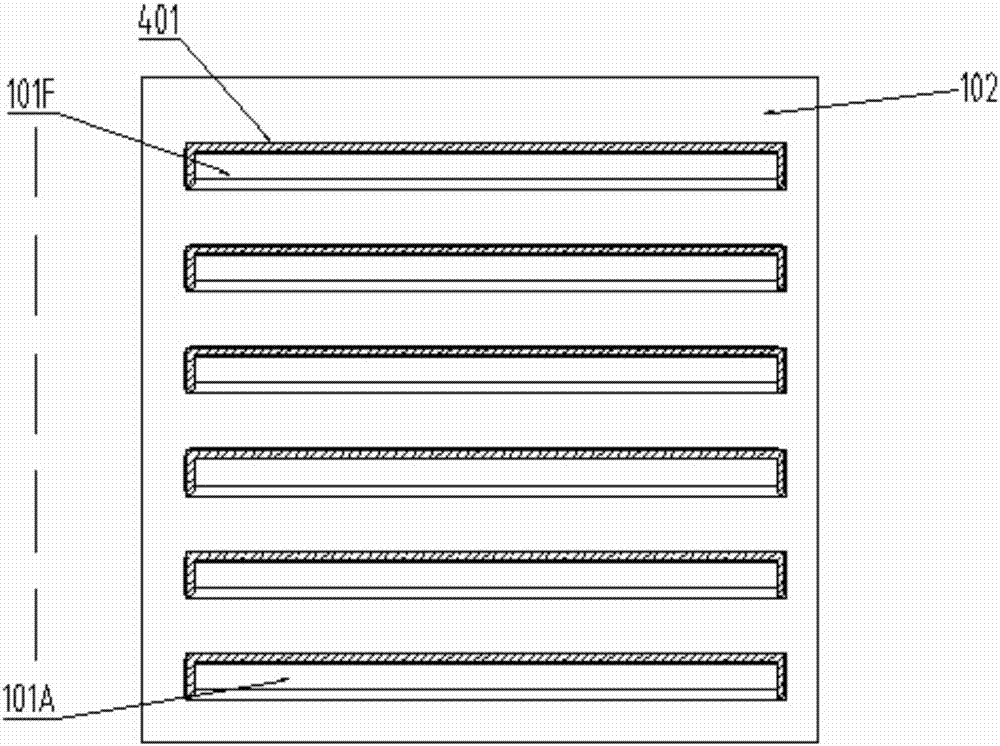

[0039] figure 1 It is the structural diagram of the array collimator of embodiment 1, figure 2 It is the layout diagram of the fixed block of the lens array frame in Embodiment 1, image 3 is the structure diagram of the lens array on the exit surface of the array collimator, Figure 4 is the focal length consistency debugging diagram of the optical fiber array, Figure 5 It is a schematic diagram of the linear misalignment of the one-dimensional lens array relative to the one-dimensional fiber array, Figure 6 It is a schematic diagram of the misalignment of the center of the one-dimensional lens array relative to the one-dimensional fiber array, Figure 7 It is a lens array linearity and center alignment debugging diagram. In this embodiment, the array collimator includes: N 1×NV grooved fiber arrays 105A-105F, 3 sets of lens array frame fixing blocks 103A, 103B, 103C, 104A, 104B , 104C, a lens array fixing frame 102, and N 1×N lens arrays 101A˜101F. Wherein the 1×N fi...

Embodiment 2

[0051] Figure 8 It is a structural diagram of the array collimator in Embodiment 2. In this embodiment, the array collimator includes: N 1×N V-groove fiber arrays 105A-105F, and three sets of lens array frame fixing blocks 103A, 103B, 103C, 104A, 104B , 104C, 1 lens array fixing frame 102, N 1×N lens arrays 101A-101F, N-1 total reflection prism strips 801A-801E, N-3 total reflection prism spacers 802A-802C. Wherein each of the 1×N fiber arrays 105A-105F is adjusted for focal length consistency and then sequentially stacked and packaged to form the N×N fiber array. One end of the lens array frame fixing block group 103A, 103B, 103C, 104A, 104B, 104C is attached to the front face of the optical fiber array, and the other end is attached to the lens array fixing frame 102, so as to realize the connection between the N×N optical fiber array and the The connection of the lens array fixing frame 102 is fixed. The 1×N lens arrays 101 are aligned with the configured 1×N optical fib...

Embodiment 3

[0066] Figure 9 It is the structural diagram of the array collimator of embodiment 3, Figure 10It is the structural diagram of the optical fiber array in Embodiment 3. In this embodiment, the array collimator includes: N 1×N V-groove arrays 903A-903F, N×N optical fibers 905, a fiber array cover plate 904, and a right-angle glass body 901, N fixed glass blocks 902 and N lens arrays 101A-101F. Wherein the N 1×N V-shaped grooves are laminated and bonded layer by layer after penetrating the N optical fibers, and the fiber array cover plate 904 is laminated and bonded on the top layer, and the N× N fiber array as a whole. The right-angled glass body 901 is glued to the bottom of the whole N×N optical fiber array. After the 1×N lens arrays 101 are in the debugging state, they are bonded and fixed with the fixed glass block 902 protruding from the step surface of the right-angled glass body 901, and repeated N times to form the N×N lens array in Example 3 layer by layer. Array ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Straightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com