Partial absorbable sport medicine orthopedic suture line and production method thereof

A technology of sports medicine and sutures, applied in the field of biomedical textile materials, can solve problems such as difficult to meet the mechanical strength requirements of joint soft tissue, infection, loose and uneven structure, and achieve the goal of facilitating cell growth and migration and promoting tissue healing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing absorbable No. 3-0 sutures for soft tissue repair in finger joints and other small joints:

[0031] The first step, fiber raw material selection: select 40dtex PPDO fiber and 40dtex ultra-high molecular weight polyethylene UHMWPE fiber;

[0032] The second step, the preparation of partially absorbable yarn for the shell layer: on the doubling machine, the above-mentioned selected 40dtex polydioxanone (PPDO) and 40dtex ultra-high molecular weight polyethylene fiber raw materials are combined into a partially absorbable yarn thread, and the yarn is wound on the knitting machine bobbin, and 8 bobbins are prepared;

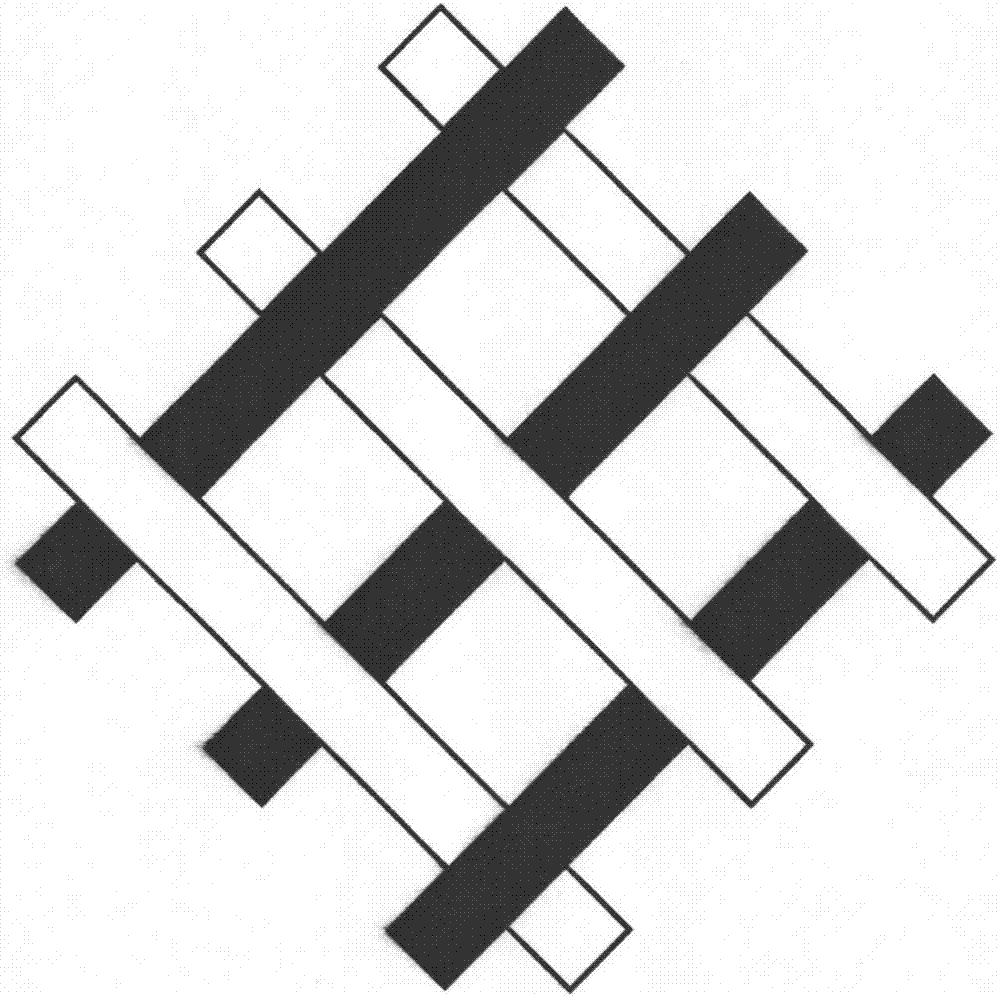

[0033] The third step, suture weaving and molding: select an 8-spindle knitting machine, pour the bobbins of 8 partially absorbable yarns prepared in the second step on the knitting machine spindle, adjust the gear ratio of the knitting machine to 82 / 20, and start Weaving machine for weaving, weaving structure such as figure 1 shown.

...

Embodiment 2

[0036] A preparation method for No. 2-0 suture for soft tissue repair of small joints such as finger joints:

[0037] The first step, fiber raw material selection: select 35dtex polycaprolactone (PCL) fiber and 35dtex ultra-high molecular weight polyethylene UHMWPE fiber;

[0038] The second step, preparation of partially absorbable yarn for the shell layer: combine the selected 35dtex PCL and 35dtex ultra-high molecular weight polyethylene UHMWPE fiber raw materials into one partially absorbable yarn on the doubling machine, and wind the yarn On the knitting machine bobbins, prepare 12 bobbins;

[0039] The third step, core yarn preparation: choose an ultra-high molecular weight polyethylene fiber UHMWPE with a linear density of 110dtex as the core yarn;

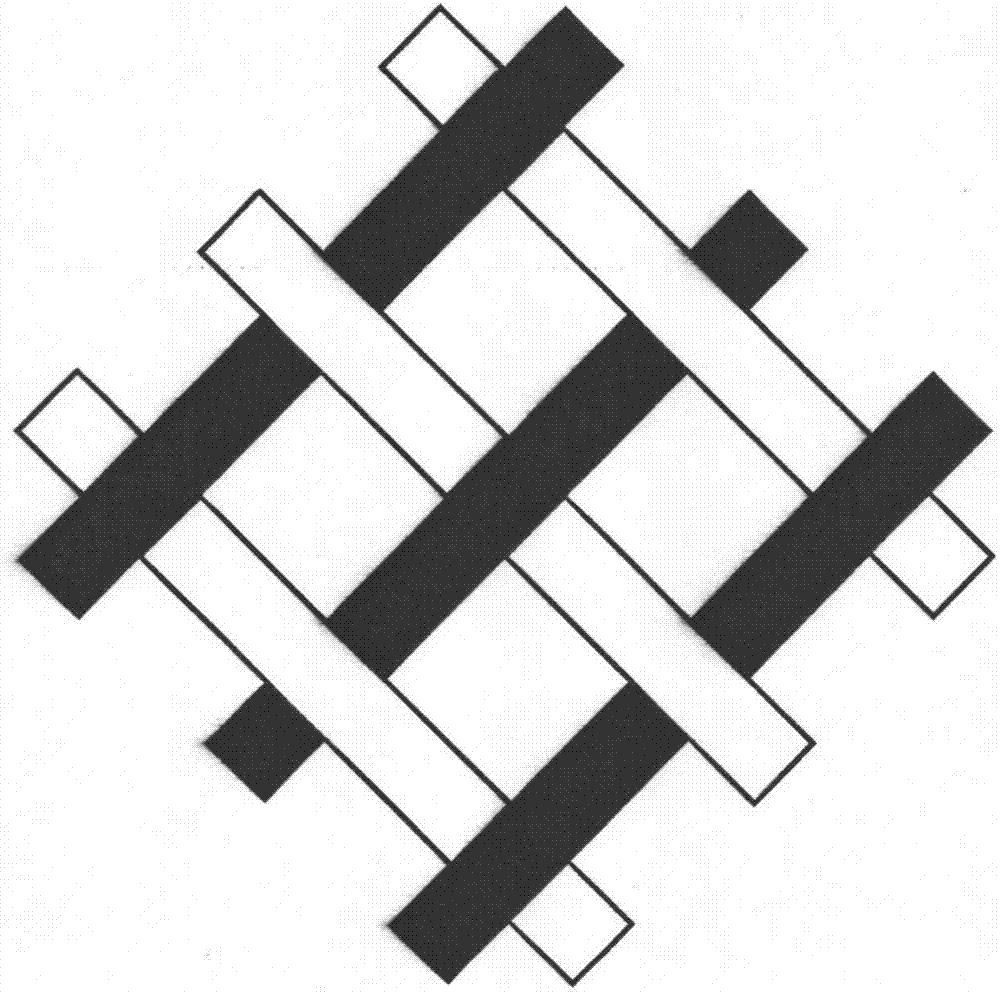

[0040] The fourth step, suture weaving and molding: select a 12-spindle braiding machine, pour the bobbins of 12 partially absorbable yarns prepared in the second step on the braiding machine spindles, and transfer the twi...

Embodiment 3

[0043] A preparation method for No. 2 sutures used for repairing knee joints, shoulder joints, Achilles tendon and other positions:

[0044] The first step, fiber raw material selection: select 55dtex polyglycolide lactide (PLGA) fiber and 55dtex ultra-high molecular weight polyethylene UHMWPE fiber;

[0045] The second step, the preparation of partially absorbable yarn for the shell layer: combine the above-mentioned selected 55dtex PLGA and 55dtex ultra-high molecular weight polyethylene UHMWPE fiber raw materials into one partially absorbable yarn on the doubling machine, and wind the yarn On the knitting machine bobbins, prepare 16 bobbins;

[0046] The third step, core yarn preparation: select 3 ultra-high molecular weight polyethylene UHMWPE fibers with a linear density of 110dtex and twist them with a twist of 40 twists / 10cm as the core yarn;

[0047] The fourth step, suture thread weaving and molding: select a 16-spindle braiding machine, pour the bobbins of 16 partia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com