Preparation method of precious metal-non-precious metal mixed catalyst

A mixed catalyst and non-precious metal technology, applied in the direction of catalyst activation/preparation, heterogeneous catalyst chemical elements, chemical instruments and methods, etc., can solve the problems of unsatisfactory catalytic efficiency, diesel vehicle exhaust pollution, poor thermal stability, etc. Achieve the effects of easy control of the preparation process, reduced emissions, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

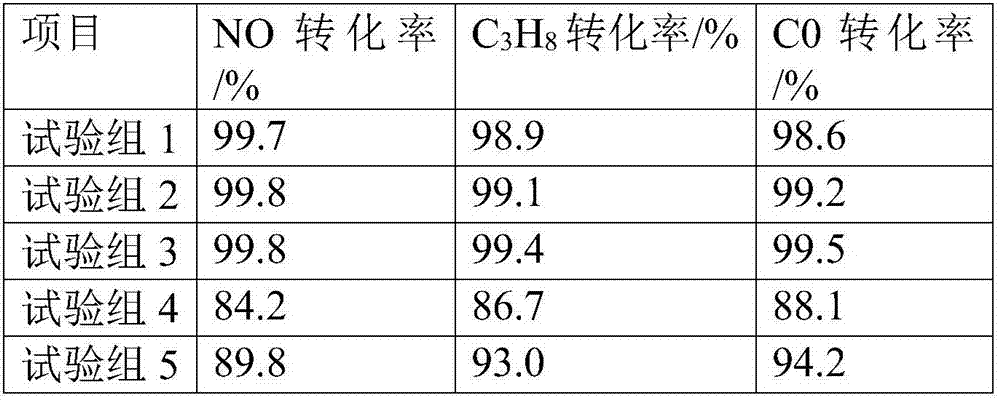

Examples

Embodiment 1

[0024] A preparation method of noble metal-non-noble metal mixed catalyst, comprising the following steps:

[0025] S1: Preparation of Au-Al 2 o 3

[0026] Add aluminum nitrate to deionized water to prepare a 0.8mol / L aluminum nitrate solution, then add laurylamine to it, and after high-speed stirring, continue to add ammonia water to it until the pH of the mixed solution is 9.5, and let it stand at room temperature for 4 Hours later, filter with suction, dry the filter residue and roast at 440°C for 80min to obtain active Al 2 o 3 ;

[0027] The active Al prepared above 2 o 3 Add it into the chloroauric acid solution, after ultrasonic treatment for 40 minutes, heat the mixed solution to 65°C, add ammonia water to the solution until the pH of the solution is 10.2, keep it warm for 2 hours, then filter and dry to obtain Au-Al 2 o 3 ;

[0028] S2: Preparation V 0.5 Ti 0.5 o 2

[0029] Mix vanadium dioxychloride, titanyl sulfate, and strontium nitrate in a mass ratio...

Embodiment 2

[0039] A preparation method of noble metal-non-noble metal mixed catalyst, comprising the following steps:

[0040] S1: Preparation of Au-Al 2 o 3

[0041] Add aluminum nitrate to deionized water to prepare a 0.8mol / L aluminum nitrate solution, then add laurylamine to it, and after high-speed stirring, continue to add ammonia water to it until the pH of the mixed solution is 10, and let it stand at room temperature for 5 Hours later, filter with suction, dry the filter residue and roast at 460°C for 90 minutes to obtain active Al 2 o 3 ;

[0042] The active Al prepared above 2 o 3 Add it to the chloroauric acid solution, ultrasonically treat it at 40-65°C for 2.5 hours, then filter and dry to obtain Au-Al 2 o 3 ;

[0043] S2: Preparation V 0.5 Ti 0.5 o 2

[0044] Mix vanadium dioxychloride, titanium oxysulfate, and strontium nitrate in a mass ratio of 1:1:3, add deionized water to it, and then add ammonia water to it until the pH of the mixed solution is 10.6, and l...

Embodiment 3

[0054] A preparation method of noble metal-non-noble metal mixed catalyst, comprising the following steps:

[0055] S1: Preparation of Au-Al 2 o 3

[0056] Add aluminum nitrate to deionized water to prepare a 0.8mol / L aluminum nitrate solution, then add laurylamine to it, and after stirring at a high speed, continuously add ammonia water to it until the pH of the mixed solution is 10.5, and let it stand at room temperature for 6 Hours later, filter with suction, dry the filter residue and roast at 480°C for 100min to obtain active Al 2 o 3 ;

[0057] The active Al prepared above 2 o 3 Add it into the chloroauric acid solution, after ultrasonic treatment for 60 minutes, heat the mixed solution to 75°C, add ammonia water to the solution until the pH of the solution is 10.7, keep it warm for 3 hours, then filter and dry to obtain Au-Al 2 o 3 ;

[0058] S2: Preparation V 0.5 Ti 0.5 o 2

[0059] After mixing vanadium dioxychloride, titanium oxysulfate, and strontium ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com