Silver/silver iodide composite material modified with cadmium tungstate and its preparation method and application

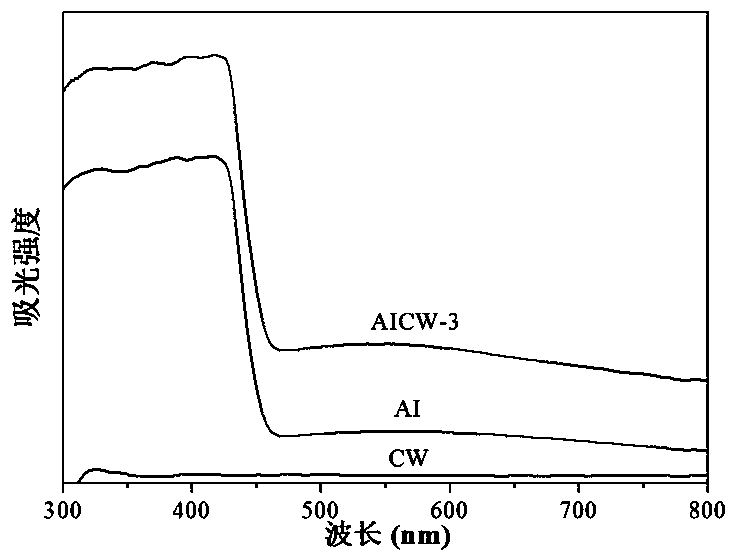

A composite material, cadmium tungstate technology, applied in chemical instruments and methods, catalyst activation/preparation, water treatment of special compounds, etc., can solve the problems of unsatisfactory separation efficiency of photogenerated charges, complex synthesis method, high temperature required, etc., to achieve The effect of photogenerated charge conduction and separation is high, the absorption range is wide, and the absorption intensity is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

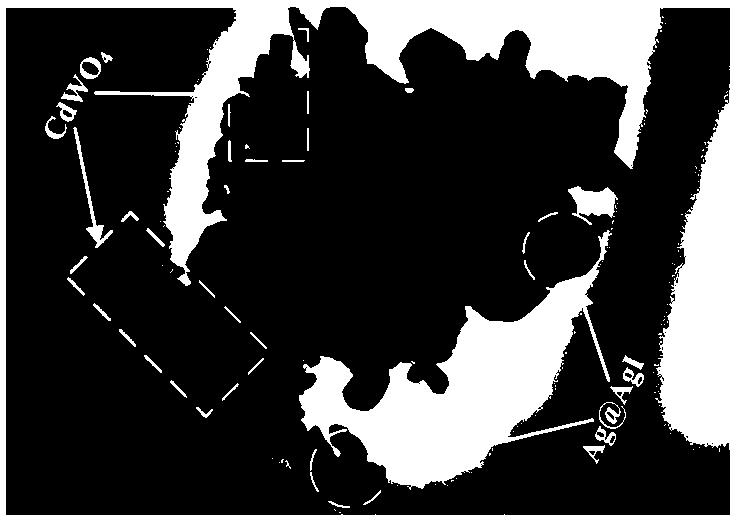

[0049] A silver / silver iodide composite material modified with cadmium tungstate comprises cadmium tungstate and silver / silver iodide material, the silver / silver iodide material is supported on cadmium tungstate, and the silver / silver iodide material is composed of Ag nanoparticles and silver iodide.

[0050] In this embodiment, in the silver / silver iodide composite material modified by cadmium tungstate, the mass percentage of Ag nanoparticles is 1.2%, the mass percentage of silver iodide is 72.4%, and the mass percentage of cadmium tungstate is 26.4%. .

[0051] In this example, the specific surface area of the silver / silver iodide composite material modified by cadmium tungstate is 3.42 m 2 / g, the average pore diameter is 6.44 nm, and the pore volume is 0.0096 cm 3 / g.

[0052] In this embodiment, the silver / silver iodide material is in the shape of random particles with a size of 200 nm to 800 nm; the cadmium tungstate is in the shape of regular nanorods with a length...

Embodiment 2

[0066] A silver / silver iodide composite material modified by cadmium tungstate, which is basically the same as the silver / silver iodide composite material modified by cadmium tungstate of Example 1, the difference being: the silver / silver iodide composite material modified by cadmium tungstate of embodiment 2 Among them, the mass percentage of Ag nanoparticles is 1.5%, the mass percentage of silver iodide is 90.3%, and the mass percentage of cadmium tungstate is 8.2%.

[0067] A kind of preparation method of the silver / silver iodide composite material modified by cadmium tungstate of the above-mentioned present embodiment is basically the same as the preparation method of the silver / silver iodide composite material modified by embodiment 1 cadmium tungstate, the difference is: embodiment 2 CdWO in step (2) 4 The dosage is 50 mg.

[0068] The silver / silver iodide composite (Ag@AgI / CdWO) modified by cadmium tungstate prepared in Example 2 4 ), denoted as AICW-1.

Embodiment 3

[0070] A silver / silver iodide composite material modified by cadmium tungstate, which is basically the same as the silver / silver iodide composite material modified by cadmium tungstate of Example 1, the difference being: the silver / silver iodide composite material modified by cadmium tungstate of embodiment 3 Among them, the mass percentage of Ag nanoparticles is 1.3%, the mass percentage of silver iodide is 83.4%, and the mass percentage of cadmium tungstate is 15.3%.

[0071] A kind of preparation method of the silver / silver iodide composite material modified by the cadmium tungstate of the above-mentioned present embodiment is basically the same as the preparation method of the silver / silver iodide composite material modified by the cadmium tungstate of embodiment 1, the difference is: embodiment 3 CdWO in step (2) 4 The dosage is 100 mg.

[0072] The silver / silver iodide composite (Ag@AgI / CdWO) modified by cadmium tungstate prepared in embodiment 3 4 ), denoted as AICW-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com