Catalyst component for olefin polymerization and catalyst containing catalyst component

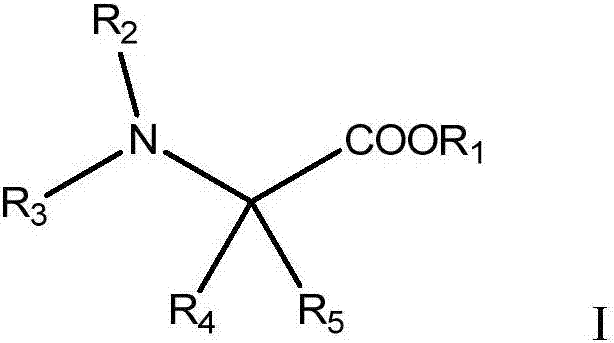

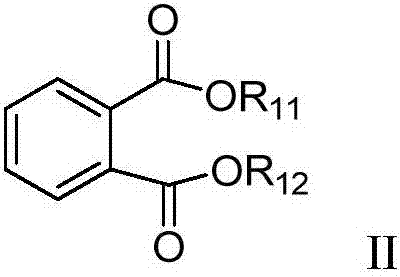

An olefin polymerization and solid catalyst technology is applied in the field of catalyst components for olefin polymerization and catalysts thereof, and can solve the problems of narrow molecular weight distribution of olefin polymers and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0111] The preparation of embodiment 1-10 solid catalyst component:

[0112] Get the alkoxymagnesium carrier 10g that makes in the preparation example, toluene 50mL, add the electron donor compound shown in Table 1 (comprising electron donor compound I and optional electron donor compound II) and be mixed with suspension; Add 40mL of toluene and 60mL of titanium tetrachloride to the 300mL reaction kettle that has been repeatedly replaced by high-purity nitrogen, then add the prepared suspension into the kettle, raise the temperature to 80°C, and continue to heat up to 115°C after constant temperature for 1 hour. After 2 hours, the liquid (mother liquor) was press-filtered clean. Add a mixed solution of 90 mL of toluene and 60 mL of titanium tetrachloride and raise the temperature to 110° C. and stir for 1 hour (titanium treatment), press filter the liquid (mother liquor), then add a mixed solution of 120 mL of toluene and 30 mL of titanium tetrachloride and raise the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com