Preparation method of self-emulsified water-based photoinitiator and water-based photoinitiator

A water-based photoinitiator, self-emulsifying technology, applied in the direction of coating, etc., can solve the problems such as the decline of the main resin performance, the low photoinitiation efficiency, the increase of the dosage, etc., to achieve good compatibility, reduce the amount of solvent, and facilitate the Emulsifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

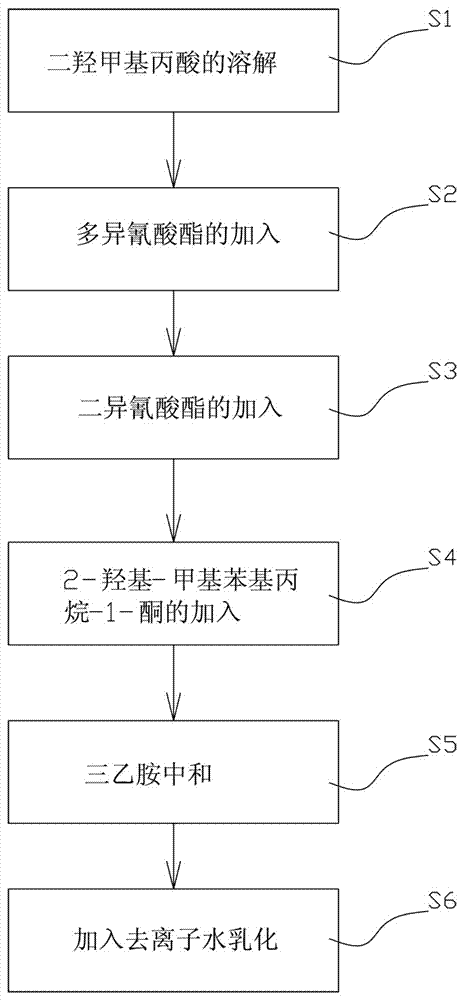

[0024] A kind of preparation method of self-emulsifying type aqueous photoinitiator, comprises the steps:

[0025] S1. Add 15 grams of dimethylolpropionic acid and 18 grams of dimethylamide into a four-necked flask equipped with a thermometer, a reflux condenser, and a mechanical stirring rod, blow nitrogen gas, and heat up to 65°C. The acid dissolves completely;

[0026] S2, drop into the mixture of 21 grams of 1,6-hexamethylene diisocyanate trimer and 0.01 grams of dibutyltin dilaurate, the time of dropping is 1 hour, and the constant temperature reaction is 3 hours;

[0027] S3. Cool down to 45° C., drop in a mixture of 27 g of isophorone diisocyanate and 0.01 g of dibutyltin dilaurate, add the mixture for 0.5 hours, keep warm for 2 hours until the isocyanate group reaches the theoretical value;

[0028] S4. Heat up to 70°C, add 18.97 grams of 2-hydroxy-methylphenylpropan-1-one and 0.01 grams of dibutyltin dilaurate to react until the isocyanate group completely disappears...

Embodiment 2

[0032] A kind of preparation method of self-emulsifying type aqueous photoinitiator, comprises the steps:

[0033] S1. Add 17 grams of dimethylolpropionic acid and 17 grams of dimethylamide into a four-necked flask equipped with a thermometer, a reflux condenser, and a mechanical stirring rod, blow nitrogen, raise the temperature to 65°C, and dissolve the dimethylolpropionic acid The acid dissolves completely;

[0034] S2, drop in the mixture of 22.76 grams of 1,6-hexamethylene diisocyanate trimer and 0.08 grams of dibutyltin dilaurate, the dropping time is 0.5 hours, and the constant temperature reaction is 2 hours;

[0035] S3. Cool down to 45°C, drop in a mixture of 25 g of isophorone diisocyanate and 0.08 g of dibutyltin dilaurate, add the mixture for 1 hour, keep warm for 1.5 hours until the isocyanate group reaches the theoretical value;

[0036] S4. Heat up to 80°C, add 18 grams of 2-hydroxy-methylphenylpropan-1-one and 0.08 grams of dibutyltin dilaurate to react until...

Embodiment 3

[0040] A kind of preparation method of self-emulsifying type aqueous photoinitiator, comprises the steps:

[0041] S1. Add 18 grams of dimethylol propionic acid and 15 grams of N-methylpyrrolidone into a four-necked flask equipped with a thermometer, a reflux condenser, and a mechanical stirring rod, blow nitrogen, and heat up to 50°C. Propionic acid is completely dissolved;

[0042] S2, drop into the mixture of 27 grams of toluene diisocyanate trimer and 0.1 gram of dibutyltin dilaurate, the dropping time is 45 minutes, constant temperature reaction for 3 hours;

[0043] S3. Cool down to 40°C, add dropwise a mixture of 20.7 g of 2,4-toluene diisocyanate and 0.1 g of dibutyltin dilaurate, add the mixture for 1 hour, and keep warm for 2 hours until the isocyanate group reaches the theoretical value;

[0044] S4. Heat up to 75°C, add 19 grams of 2-hydroxy-methylphenylpropan-1-one and 0.1 grams of dibutyltin dilaurate to react until the isocyanate group completely disappears, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com