High-adhesion UV (ultraviolet) environment-friendly spraying white primer without sanding and recoating for woodware

A white primer and recoating technology, applied in primers, coatings, epoxy resin coatings, etc., can solve the problems of limited adhesion, low recoating construction efficiency, affecting fullness and furniture aesthetics, etc. Hardness and fullness of paint film, safe and environmentally friendly preparation and use, excellent visual effect and tactile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

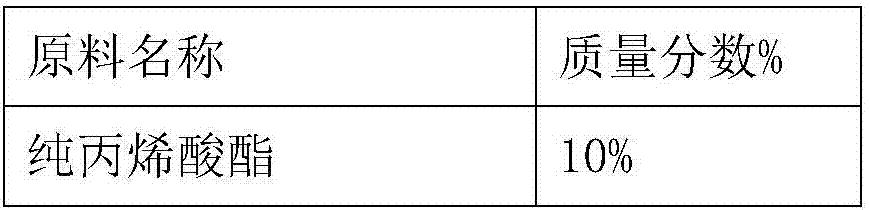

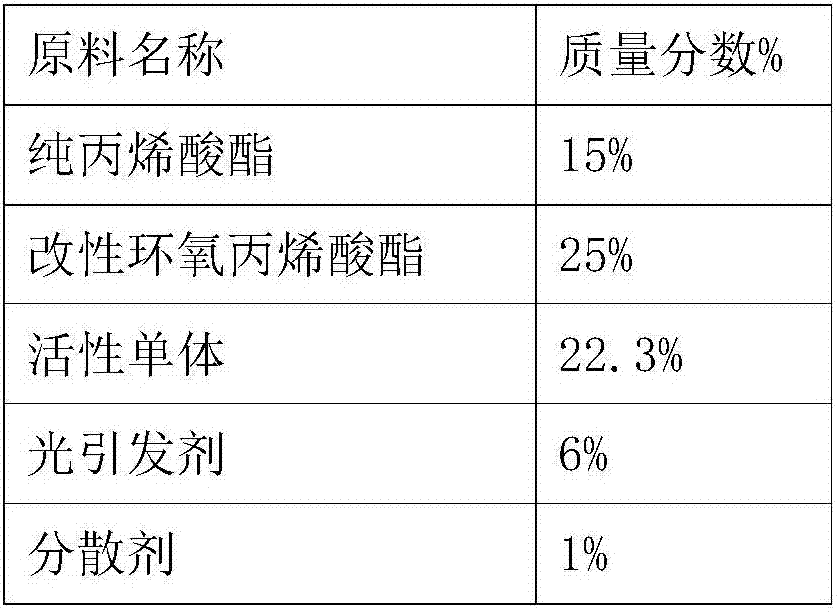

[0023] Embodiment 1: raw material proportioning is:

[0024]

[0025]

[0026] Viscosity: 180cp.

[0027] raw material name

mass fraction%

pure acrylate

15%

25%

active monomer

22.3%

6%

Dispersant

1%

0.2%

R-706

20%

1250 mesh talcum powder

10%

leveling agent

0.5%

[0028] Viscosity: 180cp.

[0029] In the embodiment of the present invention, it should be noted that the addition amount must be kept within the range, otherwise the performance and surface effect of the paint film will be affected.

[0030] In the embodiment of the invention, the raw materials used include:

[0031] Pure acrylic resin: It is acrylic modified acrylic resin, which can improve the adhesion performance of the paint film to the material and the recoating between the paint film layers.

[0032] Modified epoxy acrylate: It is acrylic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com