Automated vinegar-brewing integrated machine

An all-in-one machine and vinegar brewing technology, which is applied in the preparation of vinegar and other directions, can solve the problems of uneven heating, high labor intensity and low utilization rate of equipment, and achieves the advantages of increasing stirring force, enhancing stirring effect and high equipment utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

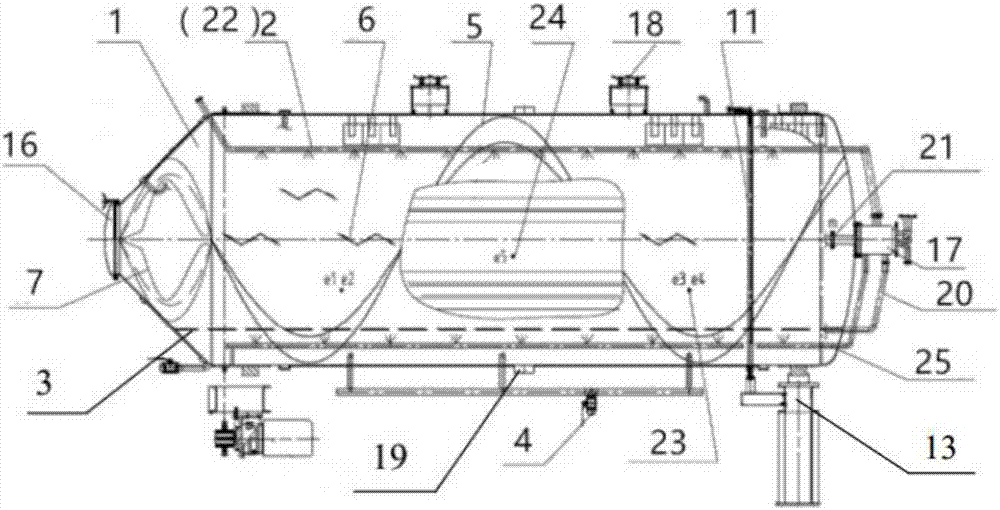

[0033] Embodiment 1 of the present invention provides an automatic vinegar brewing integrated machine, which can realize the fermentation of vinegar grains, smoked grains and vinegar pouring processes in the same equipment, eliminating the pollution and waste caused by material transportation between processes.

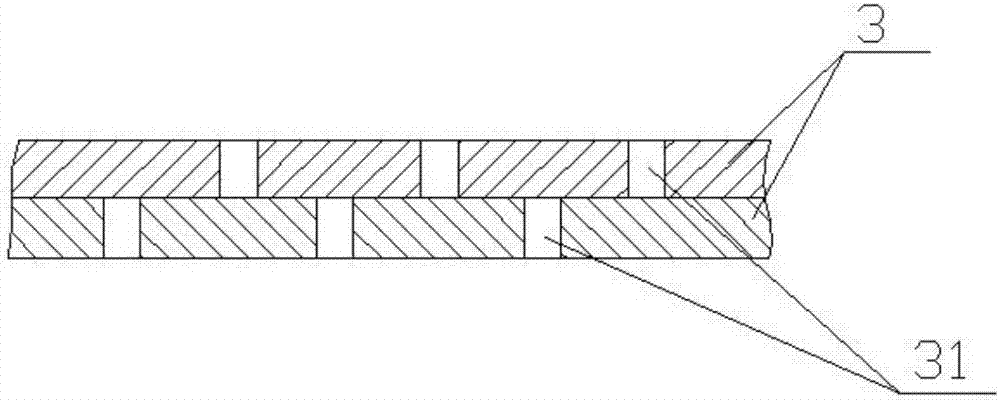

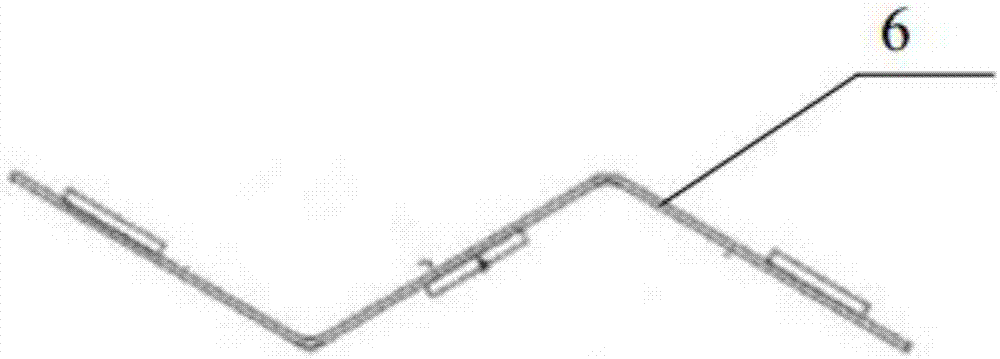

[0034] like figure 1 As shown, Embodiment 1 comprises a horizontal drum-shaped tank body 1, a heating layer, a stirring device, a spray device 2, a filtrate device and an air inlet pipe 25, wherein the air inlet pipe 25 is arranged in the tank body 1, and the heating The layer is arranged outside the tank body 1, and the heating layer can be a laser jacket or water belt for heating, and a heating medium (steam, heat transfer oil, etc.) is passed into the water belt. The internal material is heated. The stirring device and the spraying device 2 are respectively arranged in the tank body 1. The filtrate device includes a sieve plate 3 and a liquid outlet pipe 4. outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com