Method for improving growth and carbon fixation rate through improved spirulina key enzyme genes

A key enzyme gene, the technology of spirulina, applied in the field of biomass energy utilization and carbon dioxide emission reduction, can solve limited problems, increase the growth rate of carbon fixation, improve the efficiency of photosynthetic utilization and energy supply, efficient and feasible growth and solidification of spirulina Carbon rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

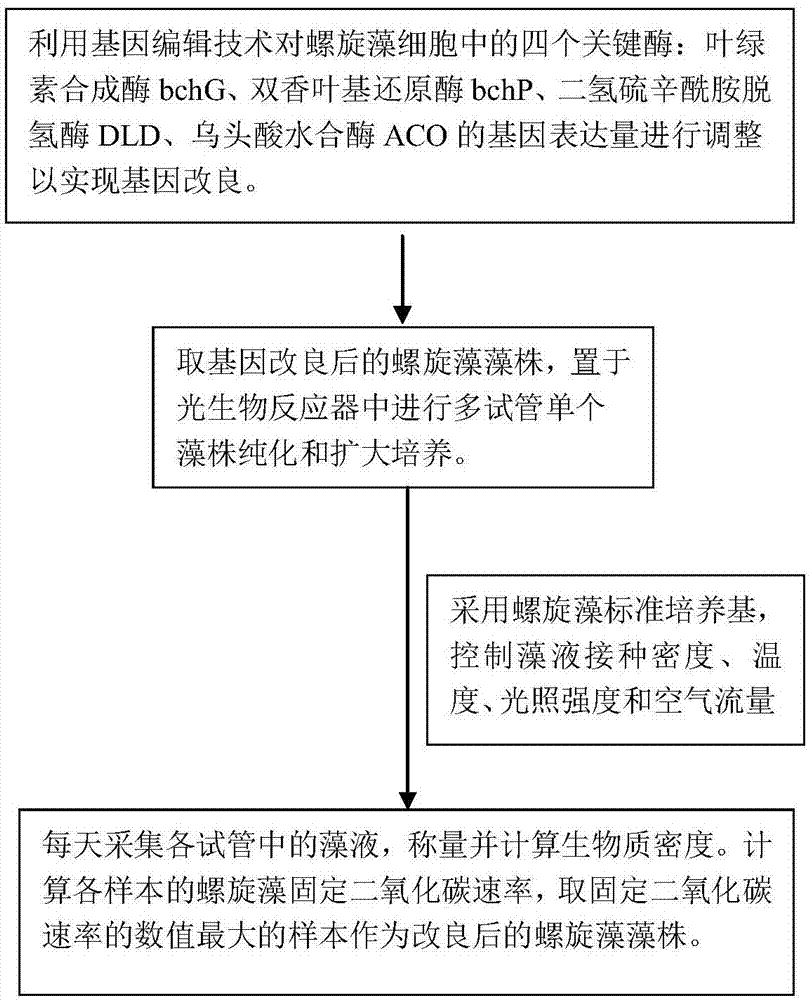

[0024] (1) Using gene editing technology to adjust the gene expression levels of four key enzymes bchG, bchP, DLD, and ACO in Spirulina cells to achieve genetic improvement: the gene expression level of chlorophyll synthase bchG was increased from 120 to 310, double The gene expression of geranyl reductase bchP was increased from 80 to 630, the gene expression of dihydrolipoamide dehydrogenase DLD was increased from 100 to 320, and the gene expression of aconitic acid hydratase ACO was increased from 170 to 460 .

[0025] (2) Take the genetically improved Spirulina strain and place it in a photobioreactor for purification and expansion of a single strain in multiple test tubes. The culture conditions are as follows: Spirulina standard medium is used, the volume of algae liquid is 300 ml, the inoculation density of algae liquid is controlled at 0.1 g / L, the temperature is 27°C, the light intensity is 7000 Lux, and the continuous air flow rate is 30 ml / min.

[0026] (3) Collect...

Embodiment 2

[0028] (1) Using gene editing technology to adjust the gene expression of four key enzymes bchG, bchP, DLD, and ACO in Spirulina cells to achieve genetic improvement: the gene expression of chlorophyll synthase bchG was increased from 130 to 330, double The gene expression of geranyl reductase bchP was increased from 90 to 650, the gene expression of dihydrolipoamide dehydrogenase DLD was increased from 110 to 340, and the gene expression of aconitic acid hydratase ACO was increased from 180 to 480 .

[0029] (2) Take the genetically improved Spirulina strain and place it in a photobioreactor for purification and expansion of a single strain in multiple test tubes. The culture conditions are as follows: Spirulina standard medium is used, the volume of algae liquid is 300 ml, the inoculation density of algae liquid is controlled at 0.1 g / L, the temperature is 27°C, the light intensity is 7000 Lux, and the continuous air flow rate is 30 ml / min.

[0030](3) Collect the algae liq...

Embodiment 3

[0032] (1) Using gene editing technology to adjust the gene expression levels of four key enzymes bchG, bchP, DLD, and ACO in Spirulina cells to achieve genetic improvement: the gene expression level of chlorophyll synthase bchG was increased from 140 to 350, double The gene expression of geranyl reductase bchP was increased from 100 to 670, the gene expression of dihydrolipoamide dehydrogenase DLD was increased from 120 to 360, and the gene expression of aconitic acid hydratase ACO was increased from 190 to 500 .

[0033] (2) Take the genetically improved Spirulina strain and place it in a photobioreactor for purification and expansion of a single strain in multiple test tubes. The culture conditions are as follows: Spirulina standard medium is used, the volume of algae liquid is 300 ml, the inoculation density of algae liquid is controlled at 0.1 g / L, the temperature is 27°C, the light intensity is 7000 Lux, and the continuous air flow rate is 30 ml / min.

[0034] (3) Collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com