Titanium alloy spectacle frame and preparation method thereof

A technology of titanium alloy and spectacle frame, which is applied in the field of glasses, can solve problems such as improving the composition of titanium alloy, and achieve the effects of improving compatibility, reducing defects, and improving melting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

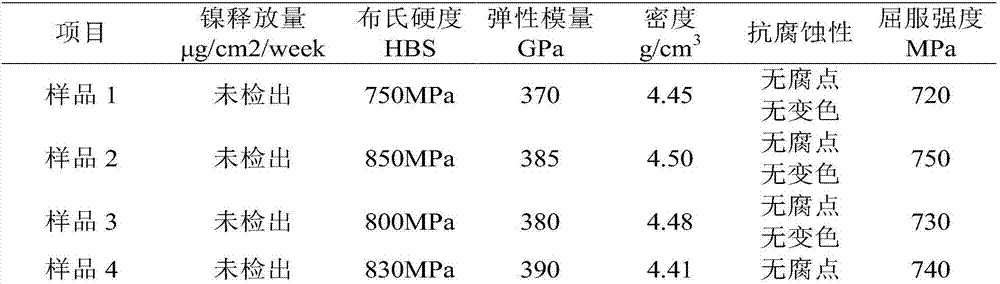

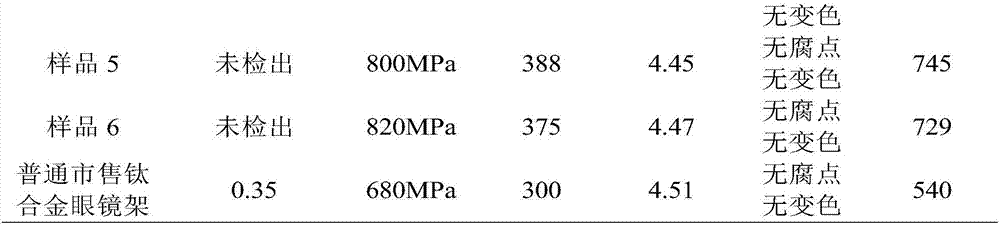

Examples

Embodiment 1

[0029] A titanium alloy spectacle frame, the composition and mass percentage of the titanium alloy are: 10% zirconium, 21% scandium, the balance of titanium and unavoidable impurities not exceeding 0.001%.

[0030] The preparation method of above-mentioned titanium alloy spectacle frame comprises the following steps:

[0031] Step 1, preparation of the master alloy: under vacuum conditions, the zirconium sponge and scandium in the mass percentage are mixed and pressed into a consumable electrode, and a zirconium scandium master alloy ingot is made in a vacuum arc consumable melting furnace;

[0032] Step 2, preparation of titanium alloy: rolling the zirconium-scandium master alloy ingot obtained in step 1 into a sheet, and rolling it into a cylindrical master alloy electrode roll; pressing the sponge titanium in the mass percentage into a cylindrical electrode block, Placed in a cylindrical intermediate alloy electrode roll, pressed into a consumable electrode, and melted into...

Embodiment 2

[0035] A titanium alloy spectacle frame, the composition and mass percentage of the titanium alloy are: 15% hafnium, 25% cobalt, the balance of titanium and unavoidable impurities not exceeding 0.001%.

[0036] The preparation method of above-mentioned titanium alloy spectacle frame comprises the following steps:

[0037] Step 1, preparation of a master alloy; mixing and pressing the hafnium and cobalt in the mass percentage into a consumable electrode, and making a hafnium-cobalt master alloy ingot in a vacuum arc consumable melting furnace;

[0038] Step 2, preparation of titanium alloy: rolling the hafnium-cobalt master alloy ingot obtained in step 1 into a sheet, and rolling it into a cylindrical master alloy electrode roll; pressing the sponge titanium in the mass percentage into a cylindrical electrode block, Placed in a cylindrical master alloy electrode roll, pressed into a consumable electrode, and melted into an ingot three times in a vacuum arc consumable melting fu...

Embodiment 3

[0041] A titanium alloy spectacle frame, the composition and mass percentage of the titanium alloy are: 10% platinum, 23% palladium, the balance of titanium and unavoidable impurities not exceeding 0.001%.

[0042] The preparation method of above-mentioned titanium alloy spectacle frame comprises the following steps:

[0043] Step 1, preparation of a master alloy; mixing and pressing the platinum and palladium in the mass percent to form a consumable electrode, and making a platinum-palladium master alloy ingot in a vacuum arc consumable smelting furnace;

[0044]Step 2, preparation of titanium alloy: rolling the platinum-palladium master alloy ingot obtained in step 1 into a sheet, and rolling it into a cylindrical master alloy electrode roll; pressing the sponge titanium in the mass percentage into a cylindrical electrode block, Placed in a cylindrical master alloy electrode roll, pressed into a consumable electrode, and melted into an ingot three times in a vacuum arc consu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com