Fluorine salt test system and method based on molten salt rector passive residual heat removal system

A technology of waste heat removal system and experimental system, which is applied in the field of passive waste heat removal system of molten salt reactor, can solve problems such as the fluorine salt circuit experimental method not involved in the overall design of the fluorine salt experimental circuit, the design method of the fluorine salt experimental circuit, etc. , to achieve the effect of ensuring the stability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

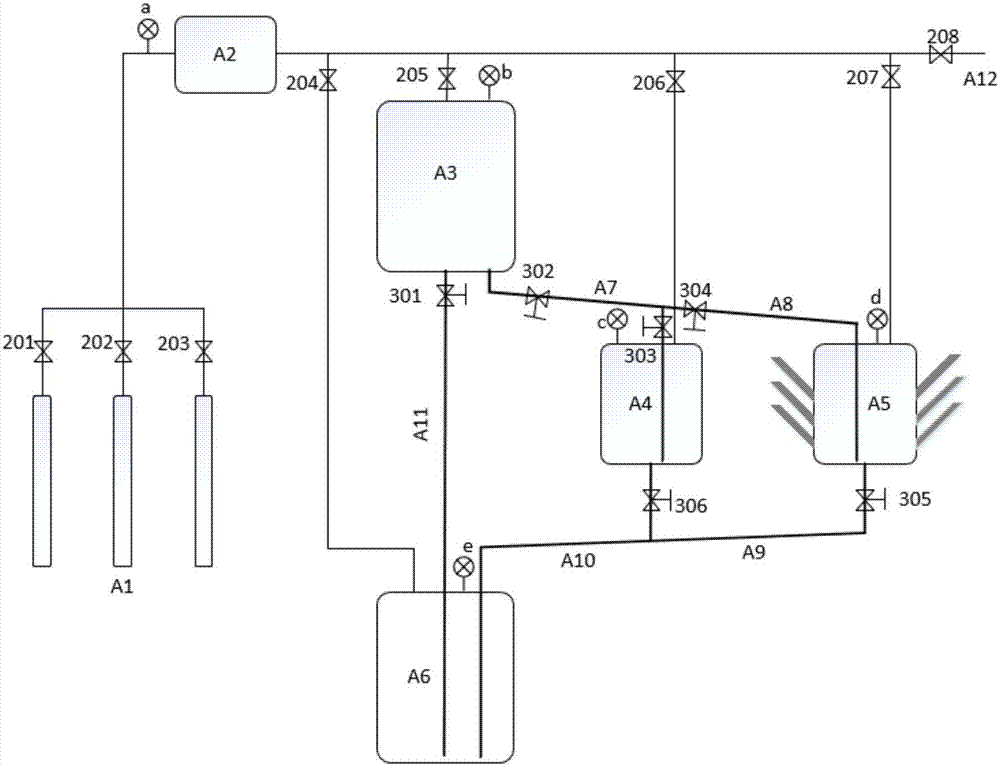

[0029] Such as figure 1 As shown, before the start of the experiment, the argon auxiliary system was used to check the tightness of the system, and the first argon valve 201, the second argon valve 202, and the third argon valve 203 were slowly opened, and the reading of the pressure gauge a rose. a After the reading is stable, open the fourth argon valve 204, the fifth argon valve 205, the sixth argon valve 206, and the seventh argon valve 207 to simulate the core tank A3, the control tank A4, the heat pipe tank A5 and the storage tank The readings of pressure gauges b, c, d and e on A6 rise, and the readings of all pressure gauges do not change significantly after a period of time, indicating that the system is well sealed. Close the first argon valve 201, the second argon valve 202 and the third argon valve 203, slowly open the eighth argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com