Catalyst for catalyzing selective hydrogenation of chloro nitro-compound

A technology for selective hydrogenation of aryl nitro compounds, applied in the preparation of amino compounds, organic compounds, physical/chemical process catalysts, etc., can solve the problems affecting the overall performance of the catalyst, the easy aggregation of platinum nanoparticles, and the complexity of the preparation process. , to achieve superior catalytic activity, solvent green and pollution-free, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

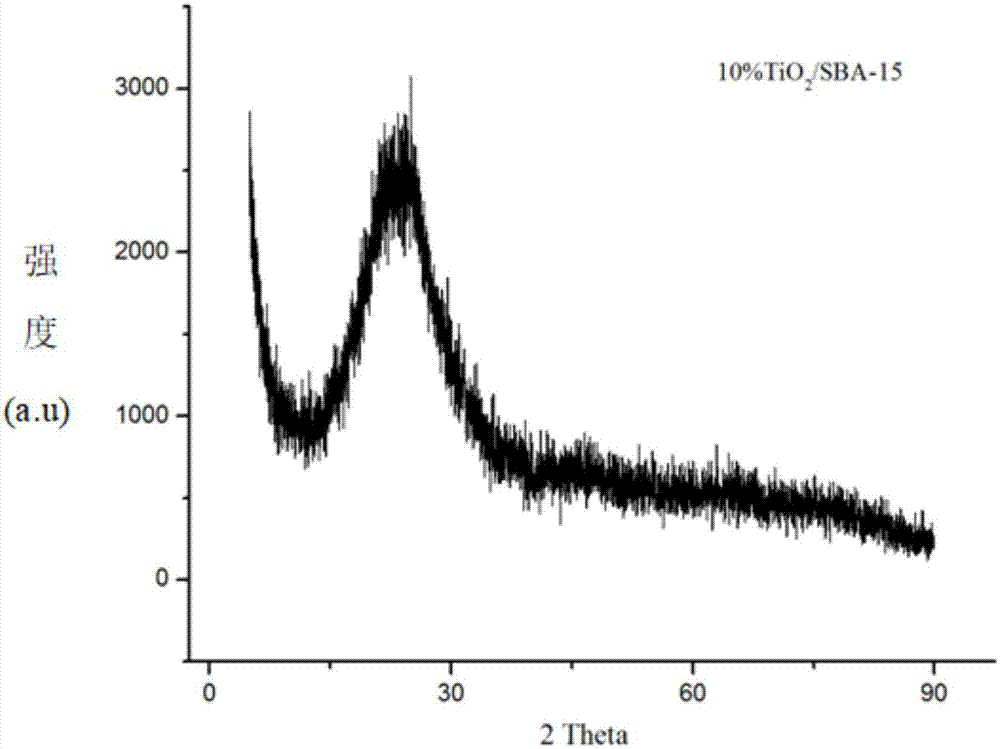

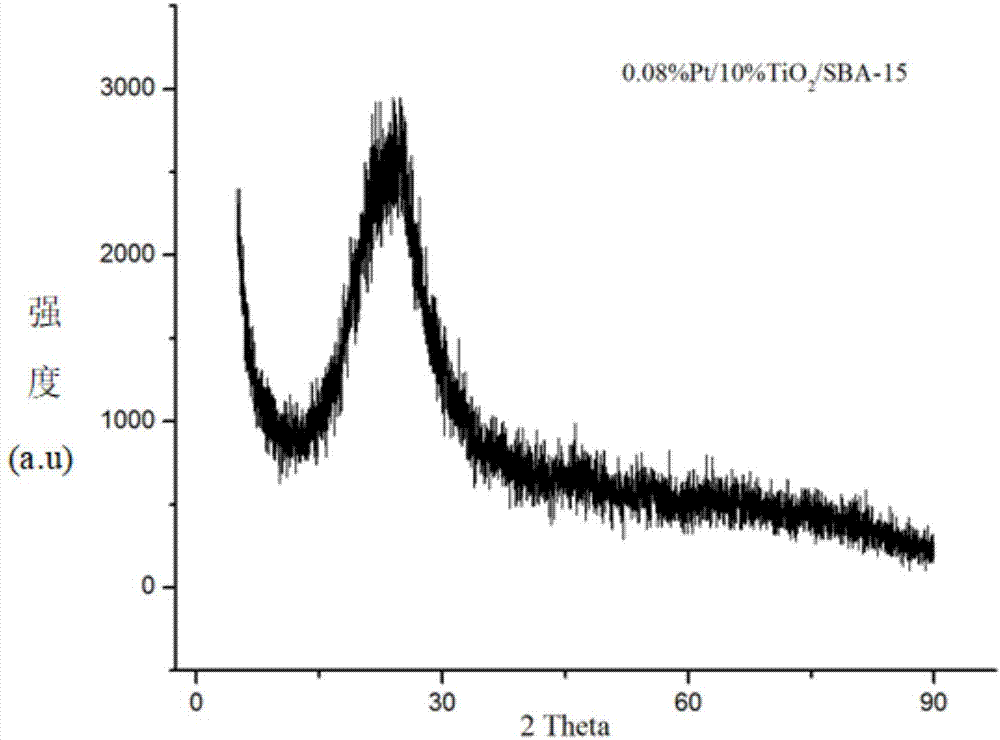

[0038] The mesoporous silicon material SBA-15 was added to 15 mL of absolute ethanol, and ultrasonically oscillated for 2 hours to obtain a mixture of treated SBA-15 and absolute ethanol. Under the condition of stirring, drop 0.5mL butyl titanate into the above mixture drop by drop, stir for 1h; slowly add 1mL water to the mixture to hydrolyze the butyl titanate, and continue stirring for 1h to completely hydrolyze the butyl titanate . Heat and stir at 40°C to make the above mixture into a gel. Vacuum drying overnight at 80°C to get 10% TiO 2 / SBA-15 composite carrier (TiO in the composite carrier 2 Content is 10wt%). Take 0.702gTiO 2 / SBA-15 composite carrier dispersed in 100mL deionized water, add 10mL anhydrous methanol, ultrasonically disperse for 10min, then add 0.1mL chloroplatinic acid solution, ultrasonically disperse for 20min, and then place the solution under ultraviolet light under stirring conditions After 12 hours, the resulting solution was filtered and was...

Embodiment 2

[0040] With embodiment 1, the difference is that Pt / TiO 2 The mass fraction of Pt in / SBA-15 is 0.08%, that is, 0.08%Pt / 10%TiO 2 / SBA-15.

Embodiment 3

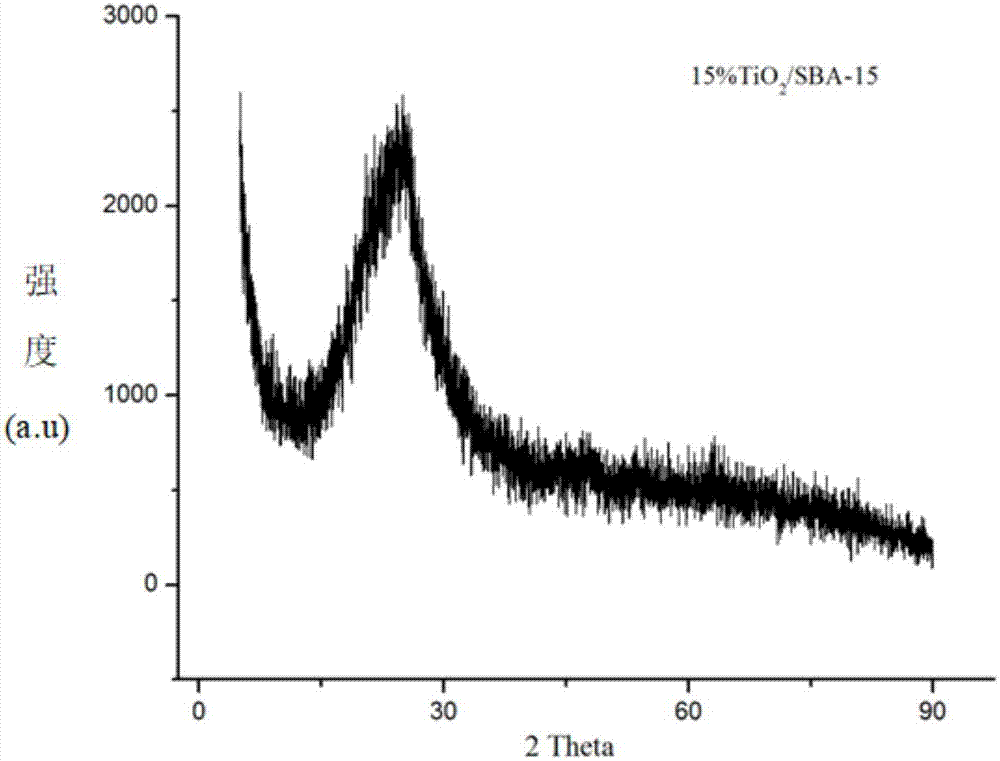

[0042] With embodiment 1, the difference is that Pt / TiO 2 / TiO in SBA-15 2 The mass fraction in the composite support is 15%, that is, 0.1%Pt / 15%TiO 2 / SBA-15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com