Atomic gas chamber of compound eye-type stacked dense multi-bubble structure, and preparation method thereof

An atomic gas cell and stack-intensive technology, which is applied in the field of atomic gas cells with compound-eye stack-intensive multi-bubble structure, can solve the problems of luminous intensity fluctuation and spectral frequency instability, achieve small temperature fluctuation and improve long-term frequency stability. degree, the effect of low temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

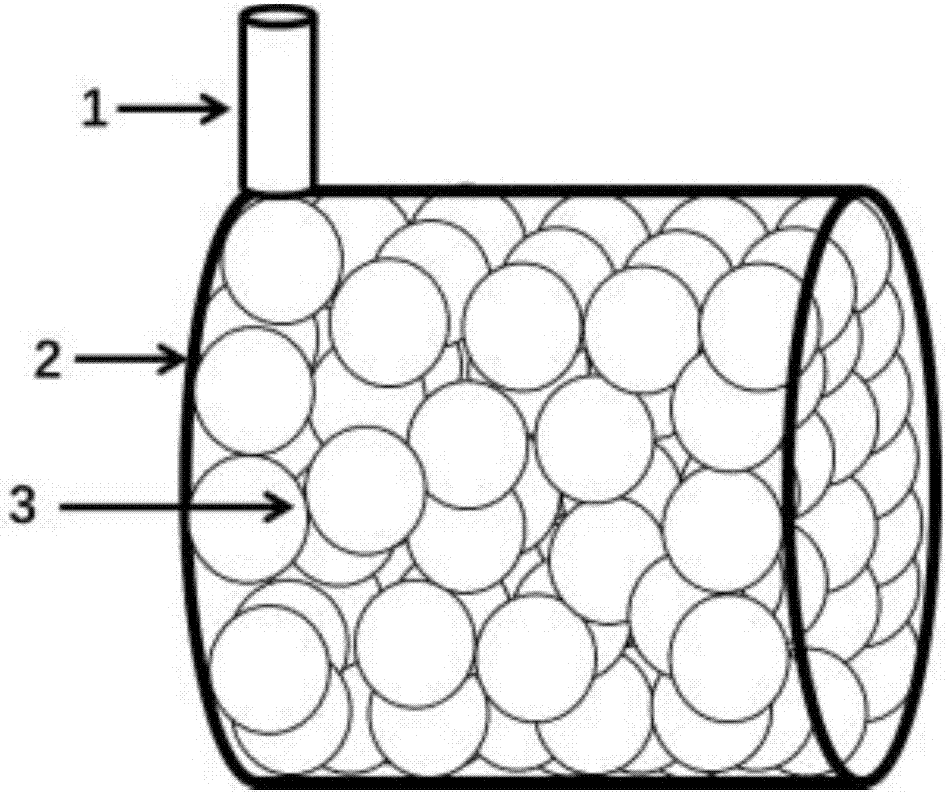

[0026] Constructed as figure 2 The shown rubidium atom gas cell includes a glass shell 2 and microatom bubbles 3 filled in the glass shell 2 . The glass shell adopts a cylindrical glass shell with a diameter of 16 and a length of 30 mm, and the diameter of the rubidium atom gas chamber 3 is 0.5 mm. The rubidium atom gas chamber 3 is filled with argon and rubidium 85 atoms.

[0027] By reserving a vent hole 1 in the glass shell 2, argon gas is filled into the glass shell 2 through the vent hole 1, so that the argon gas exists between the rubidium atom gas chambers 3, so that the multiple rubidium atom gas chambers are located The air pressure inside and outside the environment is the same, thereby reducing the penetration of rubidium atoms into the glass and stabilizing the air pressure of the rubidium atom air chamber. Then the exhaust hole 1 is closed to realize a rubidium atom gas chamber with a dense multi-bubble structure.

[0028] Since each microatomic bubble does no...

Embodiment 2

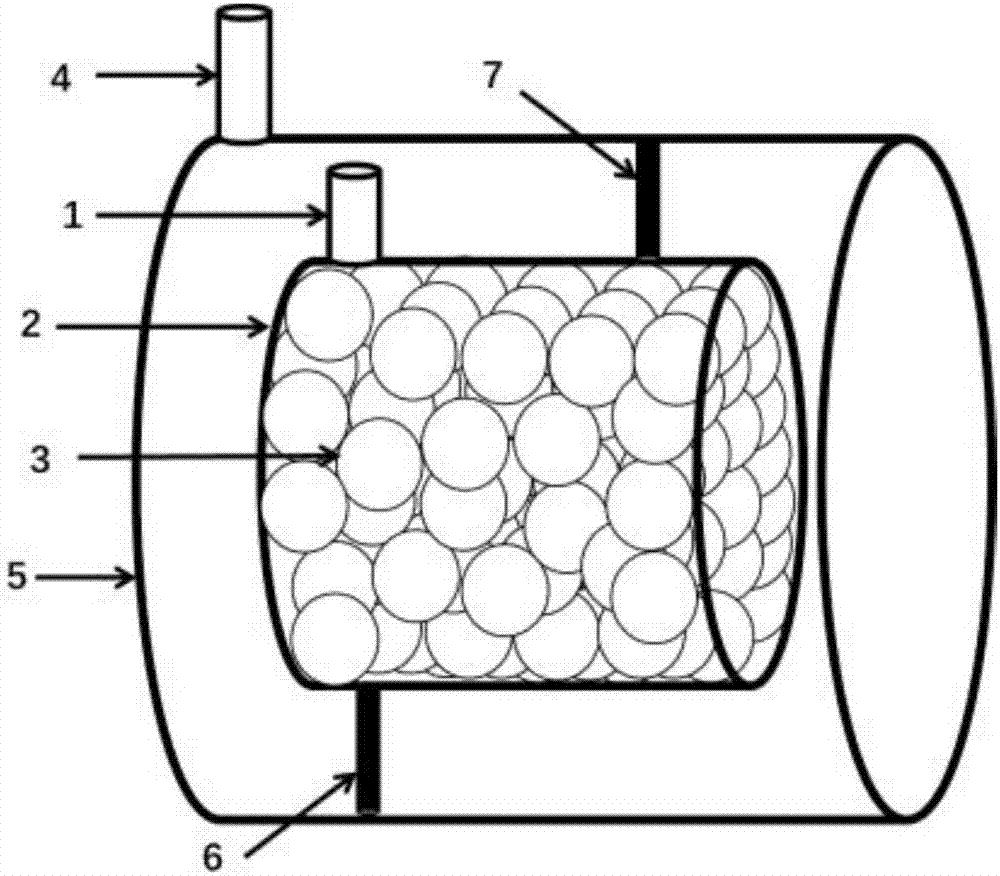

[0030] In order to further reduce temperature drift and pressure frequency shift in the gas chamber, a further second glass enclosure 5 can be set on the basis of the rubidium atom gas chamber of embodiment 1, and the rubidium atom gas chamber of embodiment 1 is fixed on the second Inside the glass enclosure 5, as image 3 shown. Through the second exhaust hole 4 reserved on the second glass shell 5, the two glass shells are evacuated to further improve the thermal insulation effect of the inner glass shell, thereby solving the long-term problem of the rubidium atomic frequency standard to a greater extent. The bottleneck problem of poor stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com