Preparation method of O-methyl-threonine/tyrosine

A technology of tyrosine and threonine, which is applied in the field of preparation of threonine/tyrosine derivatives, can solve the problems of dangerous raw materials, long steps, unfriendly environment, etc., and achieve the effect of reliable operability and short reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

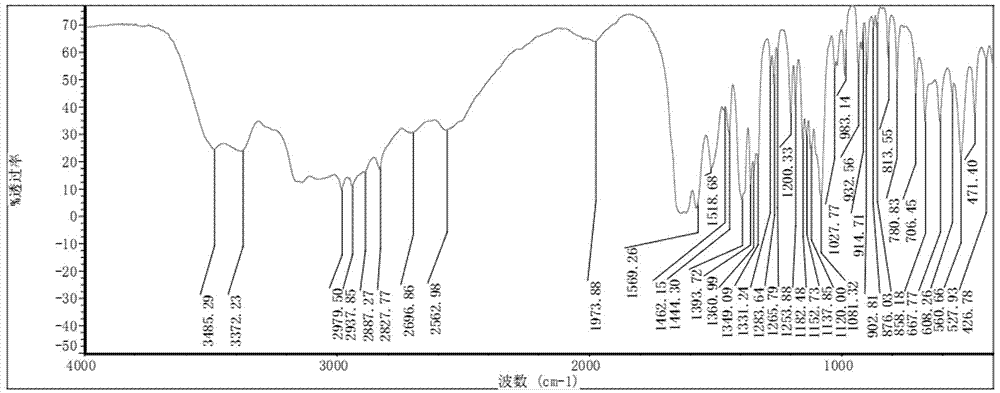

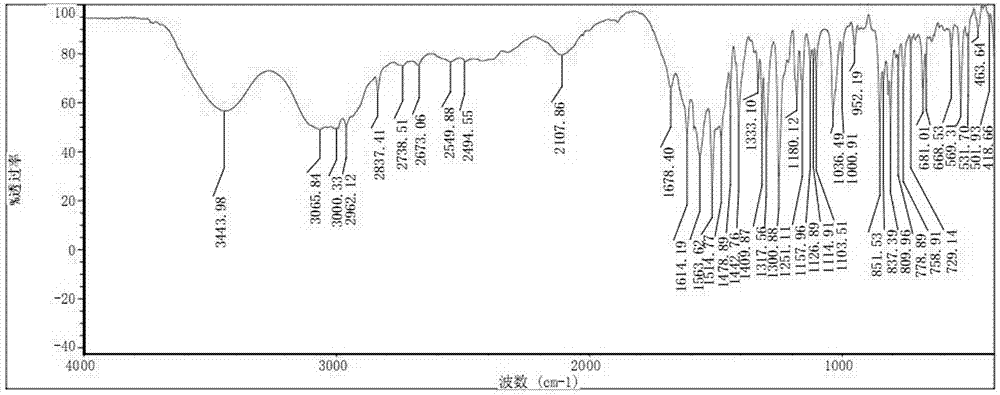

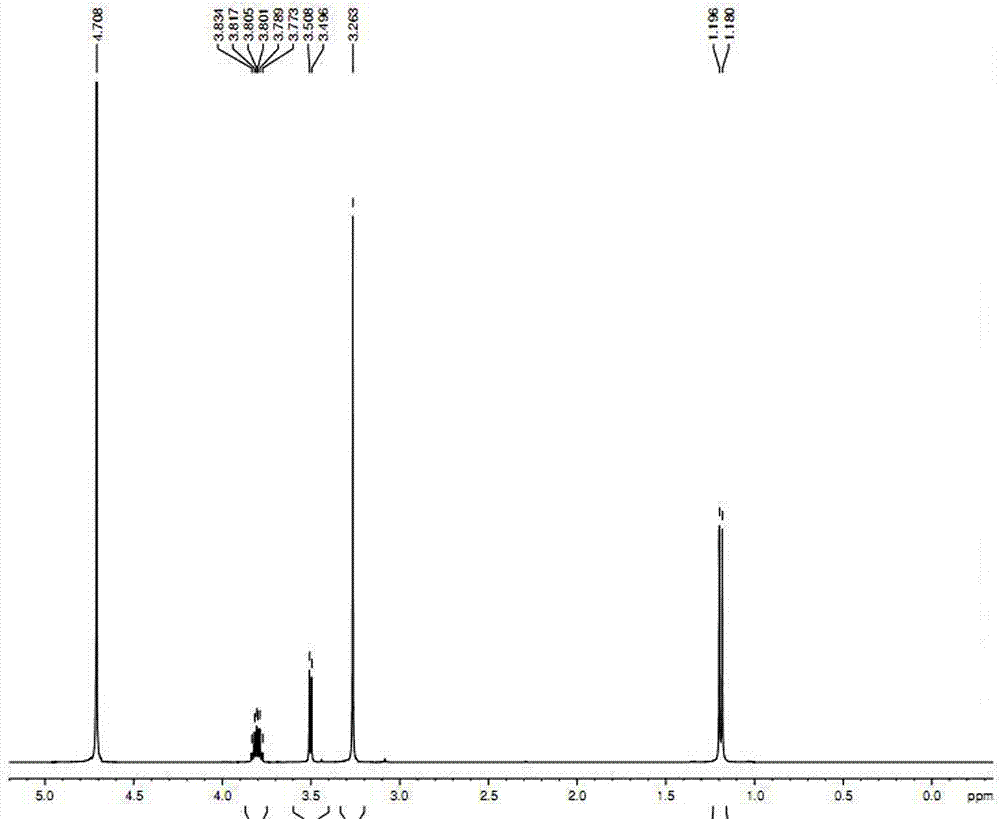

[0016] Add N-tert-butoxycarbonyl-L-threonine into acetone, after all dissolve, keep the reaction system at 20-35°C, add 8 equivalents of sodium hydroxide in batches, stir for 2 hours after the addition, keep the reaction system at 0 -20°C, add 4 equivalents of dimethyl sulfate dropwise, react overnight at room temperature (20-30°C) after addition, add water to the reaction system, evaporate acetone at 40-50°C, after removing acetone, add Ethyl acetate and crushed ice, acidified with solid citric acid to pH=2-3, separated layers, discarded the water phase, washed the oil phase with saturated brine three times, dried over sodium sulfate for 2 hours, filtered to remove sodium sulfate, evaporated Part of ethyl acetate was added with petroleum ether and stirred for crystallization to obtain N-tert-butoxycarbonyl-O-methyl-L-threonine with a yield of 61%. Dissolve N-tert-butoxycarbonyl-O-methyl-L-threonine in acetone, keep at 10-25°C, add 4 equivalents of p-toluenesulfonic acid in ba...

Embodiment 2

[0018] Add N-tert-butoxycarbonyl-D-threonine into acetone, after all dissolve, keep the reaction system at 20-35°C, add 8 equivalents of sodium hydroxide in batches, stir for 2 hours after the addition, keep the reaction system at 0 -20°C, add 4 equivalents of dimethyl sulfate dropwise, react overnight at room temperature (20-30°C) after addition, add water to the reaction system, evaporate acetone at 40-50°C, after removing acetone, add Ethyl acetate and crushed ice, acidified with solid citric acid to pH=2-3, separated layers, discarded the water phase, washed the oil phase with saturated brine three times, dried over sodium sulfate for 2 hours, filtered to remove sodium sulfate, evaporated Part of ethyl acetate was added with petroleum ether and stirred for crystallization to obtain N-tert-butoxycarbonyl-O-methyl-D-threonine with a yield of 58%. Dissolve N-tert-butoxycarbonyl-O-methyl-D-threonine in acetone, keep at 10-25°C, add an equivalent amount of trifluoroacetic acid ...

Embodiment 3

[0020] Add N-tert-butoxycarbonyl-DL-threonine into acetone, after all dissolved, keep the reaction system at 20-35°C, add 8 equivalents of sodium hydroxide in batches, stir for 2 hours after the addition, keep the reaction system at 0 -20°C, add 4 equivalents of dimethyl sulfate dropwise, react overnight at room temperature (20-30°C) after addition, add water to the reaction system, evaporate acetone at 40-50°C, after removing acetone, add Ethyl acetate and crushed ice, acidified with solid citric acid to pH=2-3, separated layers, discarded the water phase, washed the oil phase with saturated brine three times, dried over sodium sulfate for 2 hours, filtered to remove sodium sulfate, evaporated Part of ethyl acetate was added with petroleum ether and stirred to crystallize to obtain N-tert-butoxycarbonyl-O-methyl-DL-threonine with a yield of 63%. N-tert-butoxycarbonyl-O-methyl-DL-threonine was dissolved in acetone, kept at 10-25°C, added 4 equivalents of p-toluenesulfonic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com