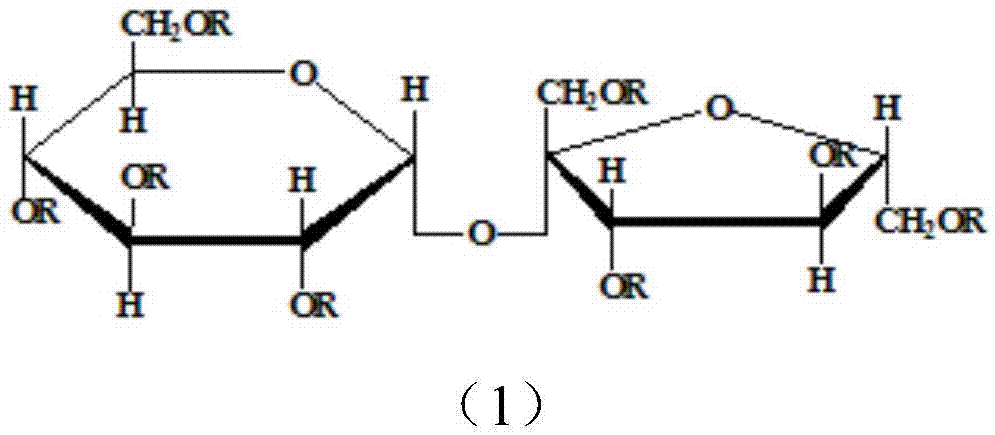

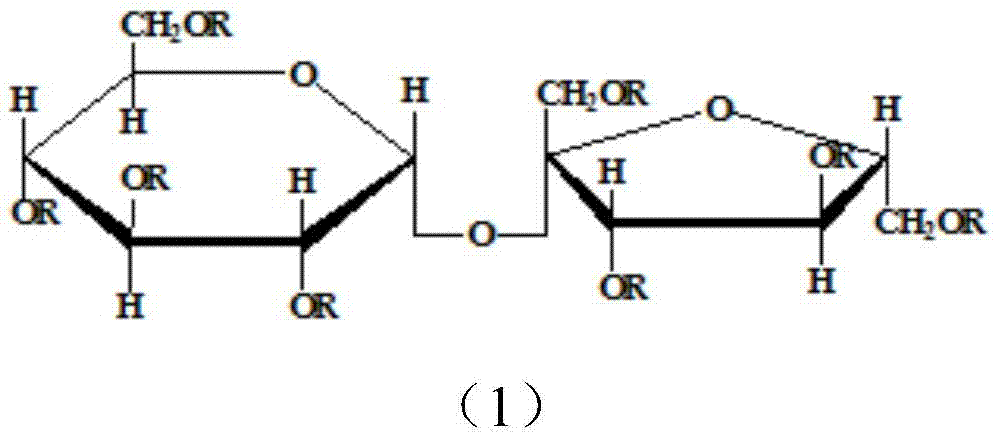

Preparation method of sucrose polyester

A technology of sucrose polyester and sucrose, which is applied in the field of preparation of sucrose polyester, can solve the problems of no industrialized production route for synthetic sucrose polyester, late development of sucrose ester, and few varieties, etc., achieve high purity and improve compatibility , The effect that the reaction is easy to carry out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Synthesis of sucrose polyester crude product:

[0032] Add 15g of water and 0.1mol sucrose to a four-necked flask equipped with a vacuum device and a stirring device, and raise the temperature to 40°C. After the sucrose is completely dissolved, add 3.0g of weakly basic catalyst sodium acetate, and then add 0.033mol of soybean oil Acetate methyl ester, turn on the vacuum to -0.065MPa, heat up to 90°C and react for 8 hours; after the reactants become homogeneous, cool down to below 80°C, release the vacuum, add 0.62mol methyl cottonseed oleate, and add medium-strength Basic catalyst potassium carbonate 2.5g, continue to turn on the vacuum to -0.095MPa, raise the temperature to 150°C and keep it warm for 12 hours to obtain the crude sucrose polyester.

[0033] (2) Removal of catalyst and unreacted sucrose from crude sucrose polyester:

[0034] After the reaction is over, add pure water with a weight 3 times that of the crude sucrose polyester, heat up to 80°C, add 10%...

Embodiment 2

[0045] (1) Synthesis of sucrose polyester crude product:

[0046] Add 30g of water and 0.1mol sucrose to a four-necked flask equipped with a vacuum device and a stirring device, and raise the temperature to 60°C. After the sucrose is completely dissolved, add 3.5g of weakly basic catalyst sodium acetate, and then add 0.24mol of soybean oil Acetate methyl ester, turn on the vacuum to -0.095MPa, heat up to 110°C and react for 3 hours; after the reactants become homogeneous, cool down to below 80°C, release the vacuum, add 0.56mol methyl soybean oleate and add a medium-strength catalyst Potassium carbonate 3.5g, continue to turn on the vacuum to -0.095MPa, raise the temperature to 120°C and keep it warm for 8 hours.

[0047] (2) Removal of catalyst and unreacted sucrose from crude sucrose polyester:

[0048] After the reaction, add pure water twice the weight of the sucrose polyester crude product, heat up to 100°C, adjust the pH to 3 by adding 10% acetic acid solution, stir for...

Embodiment 3

[0059] (1) Synthesis of sucrose polyester crude product:

[0060] Add 60g of water and 0.1mol sucrose to a four-neck flask equipped with a vacuum device and a stirring device, and heat up to 80°C. After the sucrose is completely dissolved, add 5.5g of weakly alkaline catalyst sodium acetate, and then add 0.315mol of coconut oil Methyl cocoate, turn on the vacuum to -0.085MPa, heat up to 100°C and react for 7 hours; after the reactants become homogeneous, cool down to below 80°C, release the vacuum, add 0.735mol methyl coconut oleate and add a medium-strength catalyst Potassium carbonate 5.0g, continue to turn on the vacuum to -0.095MPa, raise the temperature to 115°C and keep it warm for 10 hours.

[0061] (2) Removal of catalyst and unreacted sucrose from crude sucrose polyester:

[0062] After the reaction is over, add pure water with a weight 2.5 times that of the crude sucrose polyester, heat up to 90°C, add 10% acetic acid solution to adjust the pH to 6, stir for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com