Construction method for prestressed reinforced concrete-made circular arch-shaped tower

A technology of reinforced concrete and construction methods, applied to bridge parts, erection/assembly of bridges, bridge materials, etc., can solve the problems of high bearing capacity of foundation foundation, high requirements for pouring quality control measures, and large consumption of support formwork, etc. Achieve the effects of ensuring operational safety, meeting design technical requirements and structural installation quality, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

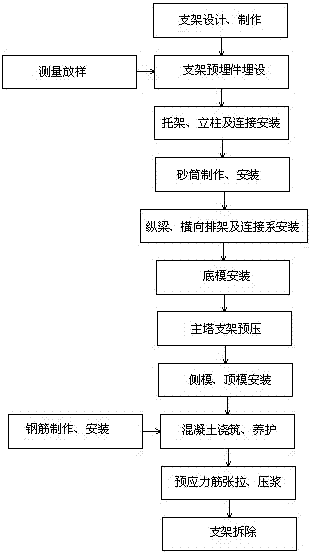

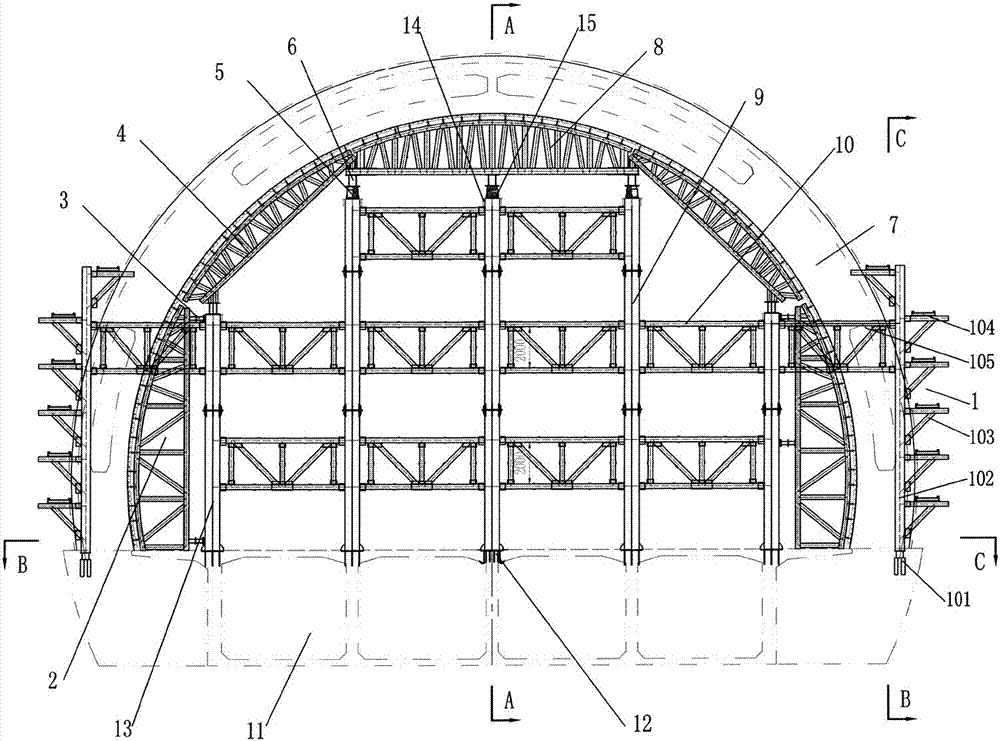

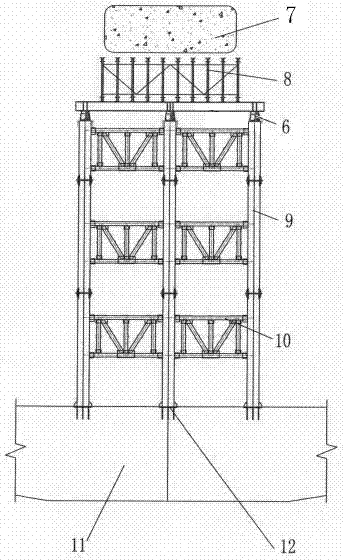

[0038] Such as Figure 1-4 Shown, the construction method of prestressed reinforced concrete circular arch tower of the present invention comprises measurement lofting; Support design and manufacture; Design, manufacture of formwork; Embedded parts are embedded; Bracket, column and connecting system are installed; Installation; the installation of longitudinal beams, horizontal bent frames and connecting systems, specifically includes the following steps:

[0039] 1) Measurement and stakeout: the establishment of the construction control network, including the re-testing of the main control network and the encryption of the construction control network points, the detailed construction and precise positioning of geometric dimensions, inclination angles, line types, etc., and checking the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com