Preparation method and application of silver iodide/bismuth selenate composite material

A composite material, silver iodide technology, applied in catalyst activation/preparation, chemical instruments and methods, oxidation preparation of carbonyl compounds, etc., can solve problems such as uncontrollable, many steps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

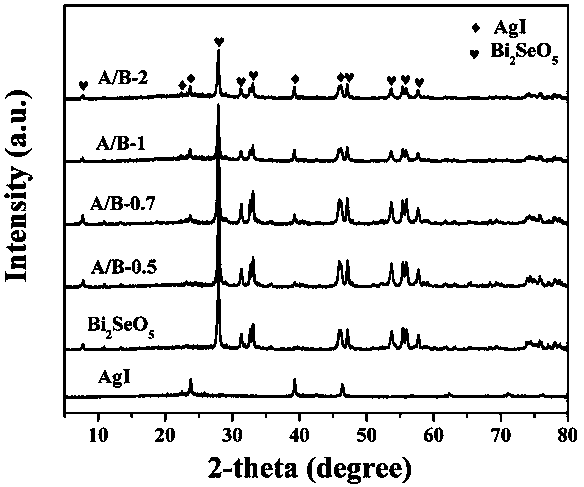

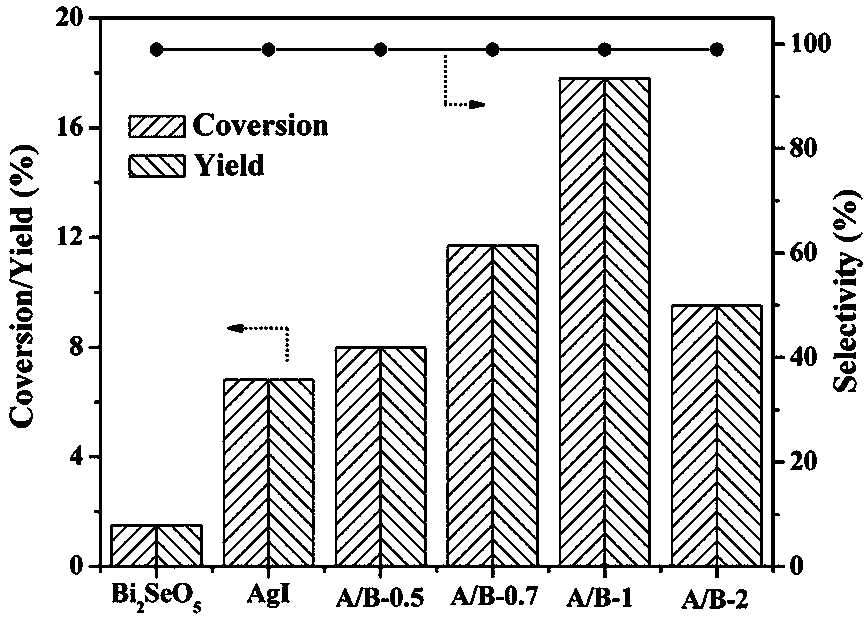

[0023] (1) Photocatalyst Bi 2 SeO 5 Preparation: 2 mmol of bismuth oxide, 3 mmol of selenium powder and 0.5 g of sodium borohydride were mixed evenly, placed in a muffle furnace, and calcined at 500 °C for 3 h in an air atmosphere.

[0024] (2) Composite photocatalyst AgI / Bi 2 SeO 5 Preparation: AgI / Bi with a molar percentage of AgI of 0.5% was prepared by in-situ deposition method 2 SeO 5 Complex, weigh 0.40 mmol Bi 2 SeO 5 The powder was dispersed in 25 mL of deionized water, and then 10 mL of AgNO was added to the resulting solution 3 solution (containing 2 μmol AgNO 3 ); stirred in the dark for 30 min, then added 25 mL of a solution containing 2 μmol KI dropwise until the solution turned bright yellow; centrifuged, washed the precipitate with distilled water and absolute ethanol, and dried in vacuum at 60 °C for 2 h to obtain AgI / Bi 2 SeO 5 Composite precursor; the resulting precursor can be calcined at 200 ℃ for 0.5 h in a nitrogen-hydrogen mixture with a hydro...

Embodiment 2

[0026](1) Photocatalyst Bi 2 SeO 5 Preparation: 2 mmol of bismuth oxide, 3 mmol of selenium powder and 0.5 g of sodium borohydride were mixed evenly, placed in a muffle furnace, and calcined at 500 °C for 3 h in an air atmosphere.

[0027] (2) Composite photocatalyst AgI / Bi 2 SeO 5 Preparation: AgI / Bi with a molar percentage of AgI of 0.7% was prepared by in-situ deposition method 2 SeO 5 Complex, weigh 0.40 mmol Bi 2 SeO 5 The powder was dispersed in 25 mL of deionized water, and then 10 mL of AgNO was added to the resulting solution 3 solution (containing 2.8 μmol AgNO 3 ); stirred in the dark for 30 min, then added 25 mL of a solution containing 2.8 μmol KI dropwise until the solution turned bright yellow; centrifuged, washed the precipitate with distilled water and absolute ethanol, and dried in vacuum at 60 °C for 2 h to obtain AgI / Bi 2 SeO 5 Composite precursor; the resulting precursor can be calcined at 500 ℃ for 0.5 h in a nitrogen-hydrogen mixture with a hyd...

Embodiment 3

[0029] (1) Photocatalyst Bi 2 SeO 5 Preparation: 2 mmol of bismuth oxide, 3 mmol of selenium powder and 0.5 g of sodium borohydride were mixed evenly, placed in a muffle furnace, and calcined at 500 °C for 3 h in an air atmosphere.

[0030] (2) Composite photocatalyst AgI / Bi 2 SeO 5 Preparation: AgI / Bi with a molar percentage of AgI of 1% was prepared by in-situ deposition 2 SeO 5 Complex, weigh 0.40 mmol Bi 2 SeO 5 The powder was dispersed in 25 mL of deionized water, and then 10 mL of AgNO was added to the resulting solution 3 solution (containing 4 μmol AgNO 3 ); stirred in the dark for 30 min, then added 25 mL of a solution containing 4 μmol KI dropwise until the solution turned bright yellow; centrifuged, washed the precipitate with distilled water and absolute ethanol, and dried in vacuum at 60 °C for 2 h to obtain AgI / Bi 2 SeO 5 Composite precursor; the resulting precursor can be calcined at 300 ℃ for 4 h in a nitrogen-hydrogen mixture with a hydrogen content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com