Preparation method and application of a carbon nitride/bismuth selenate composite material

A composite material, bismuth selenate technology, applied in catalyst activation/preparation, chemical instruments and methods, oxidation preparation of carbonyl compounds, etc., can solve the problem of no research report on nano-composite photocatalysts, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

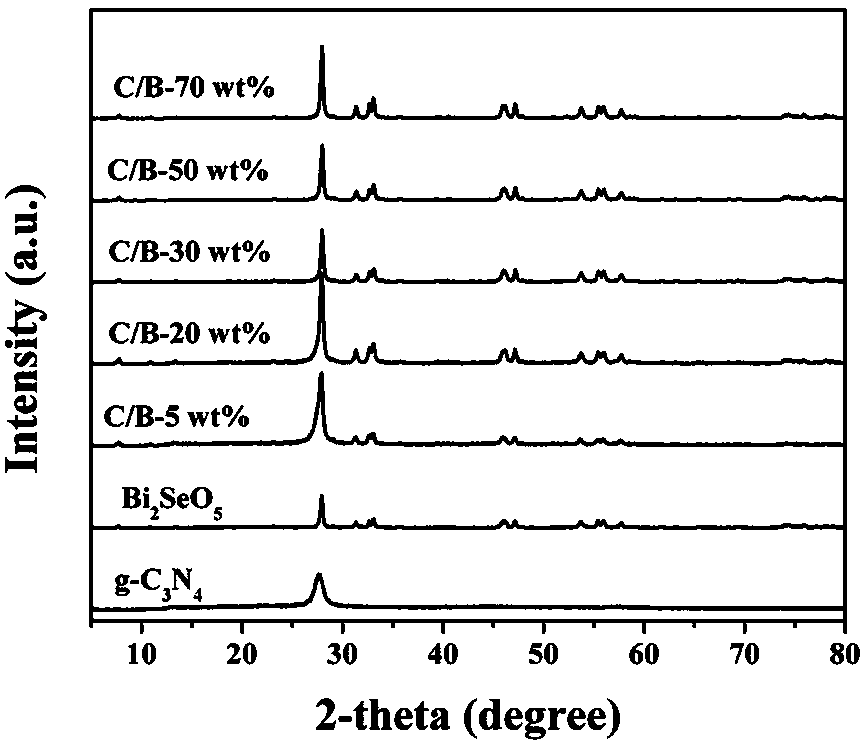

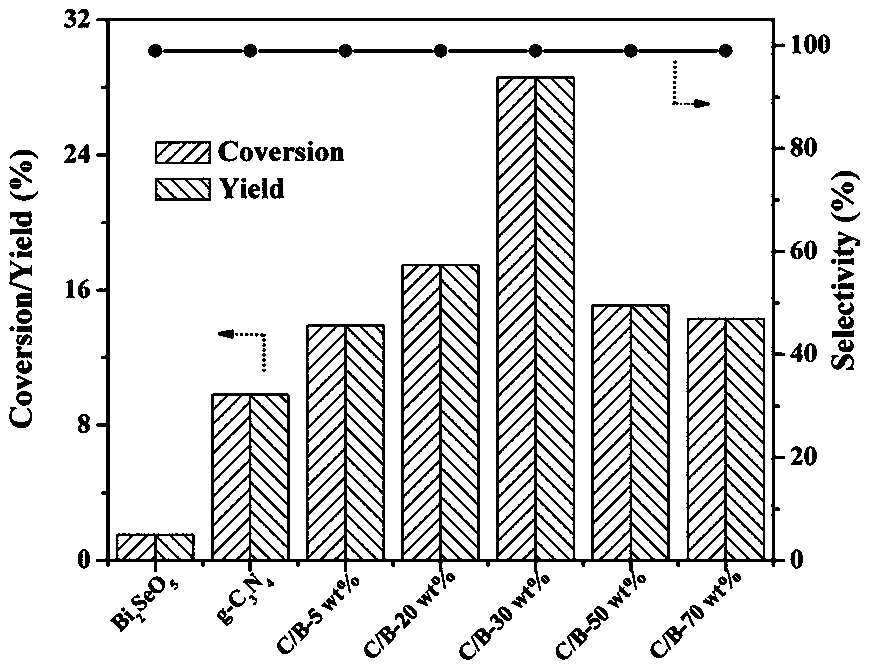

Embodiment 1

[0022] (1) Mix 2 mmol of bismuth carbonate and 3 mmol of selenium powder evenly, place them in a muffle furnace, and calcinate at 500 °C for 3 h in a hydrogen-nitrogen mixed atmosphere with a hydrogen content of 20 v / v% (the heating rate is 5 ℃ / min), the obtained solid sample is Bi 2 SeO 5 ;

[0023] (2) Add 0.5 g of urea powder into water, heat to 100 ℃ to dissolve, then add 10 g of Bi under the action of ultrasound 2 SeO 5 powder, stirred for 6 hours, cooled to room temperature, centrifuged and dried in an oven at 80 °C, the dried sample was fully ground and placed in a tube furnace, mixed with hydrogen and nitrogen with a hydrogen content of 0.5v / v% In air, calcined at 350 °C for 2 h (heating rate 1 °C / min), you can get g-C 3 N 4 / Bi 2 SeO 5 Composite; the resulting sample is denoted as C / B-5 wt%.

Embodiment 2

[0025] (1) Mix 2 mmol of bismuth carbonate and 3 mmol of selenium powder evenly, place them in a muffle furnace, and calcinate at 500 °C for 3 h in a hydrogen-nitrogen mixed atmosphere with a hydrogen content of 0.5 v / v% (heating rate is 5 ℃ / min), the obtained solid sample is Bi 2 SeO 5 ;

[0026] (2) Add 2 g of urea powder into water, heat to 100 °C to dissolve, then add 10 g of Bi 2 SeO 5 powder, stirred for 6 hours, cooled to room temperature, centrifuged and dried in an oven at 80 °C, the dried sample was fully ground and placed in a tube furnace, in a hydrogen-nitrogen mixture with a hydrogen content of 20v / v% , calcined at 500 °C for 2 h (heating rate 3 °C / min), to obtain g-C 3 N 4 / Bi 2 SeO 5 Composite; the resulting sample is noted as C / B-20 wt%.

Embodiment 3

[0028] (1) Mix 2 mmol of bismuth carbonate and 3 mmol of selenium powder evenly, place them in a muffle furnace, and calcinate at 500 °C for 3 h in a hydrogen-nitrogen mixed atmosphere with a hydrogen content of 10 v / v% (the heating rate is 10 ℃ / min), the obtained solid sample is Bi 2 SeO 5 ;

[0029] (2) Add 3 g of urea powder into water, heat to 100 °C to dissolve, then add 10 g of Bi 2 SeO 5 powder, stirred for 6 hours, cooled to room temperature, centrifuged and dried in an oven at 80 °C, the dried sample was fully ground and placed in a tube furnace, mixed with hydrogen and nitrogen with a hydrogen content of 0.5v / v% In air, calcined at 400 °C for 2 h (heating rate 5 °C / min), you can get g-C 3 N 4 / Bi 2 SeO 5 Composite; the resulting sample is denoted as C / B-30 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com