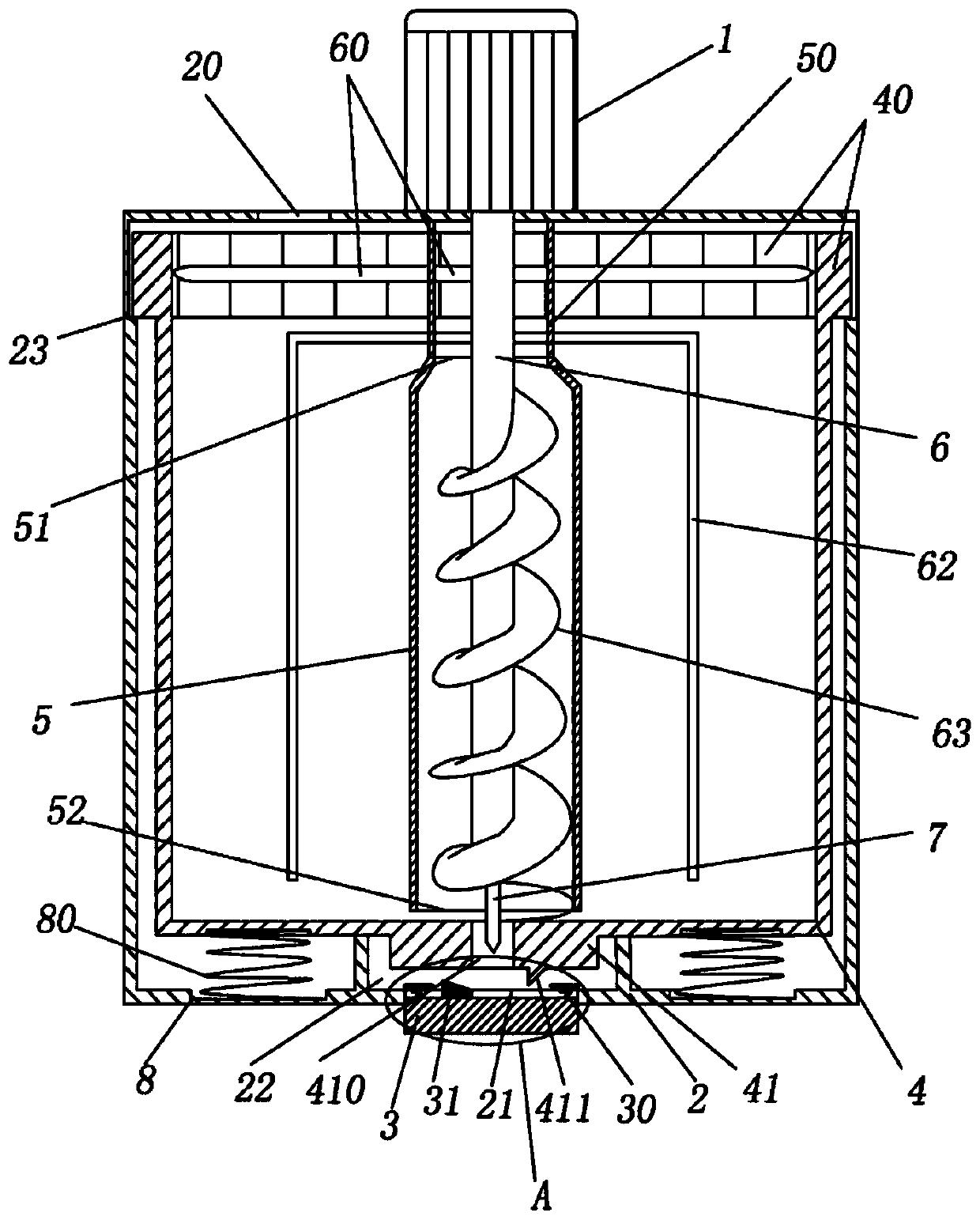

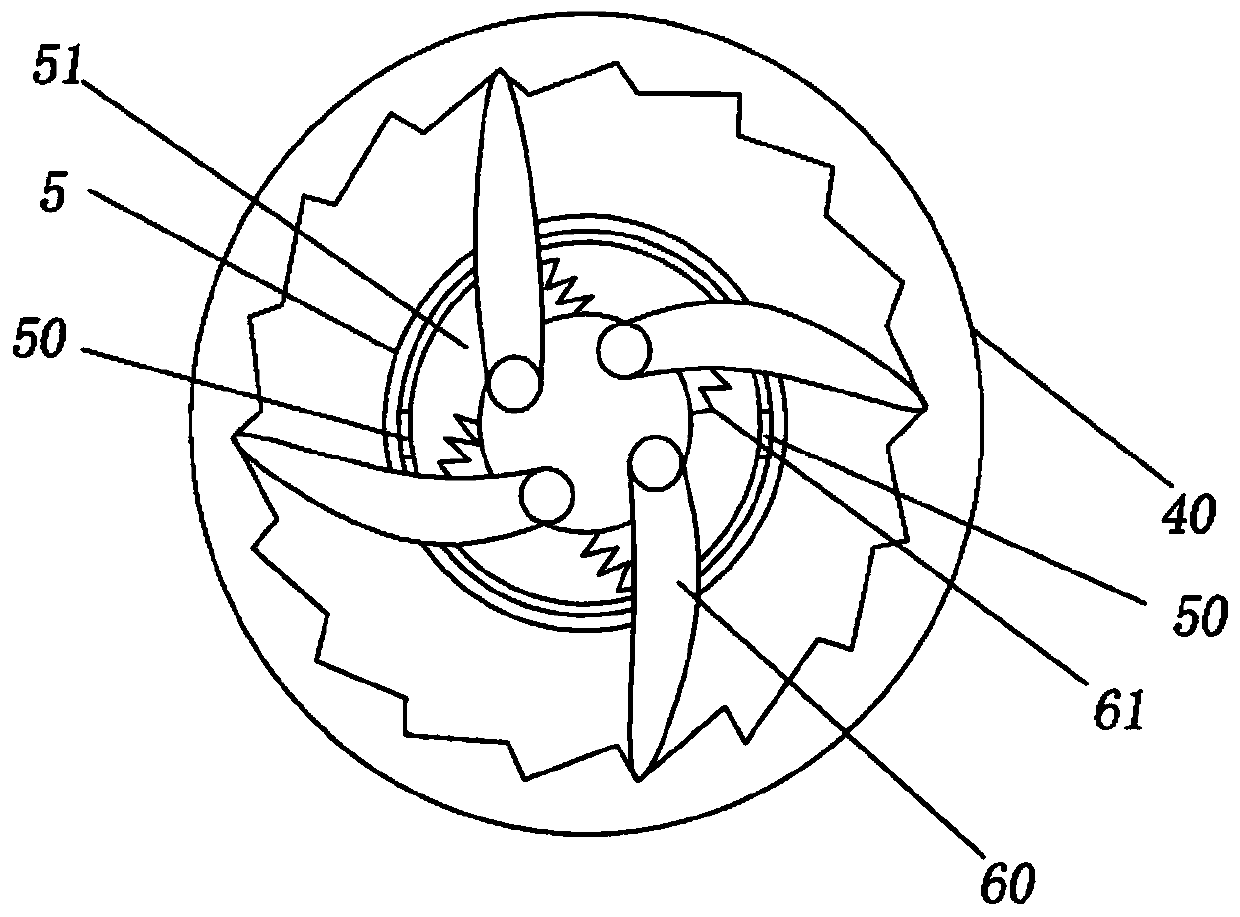

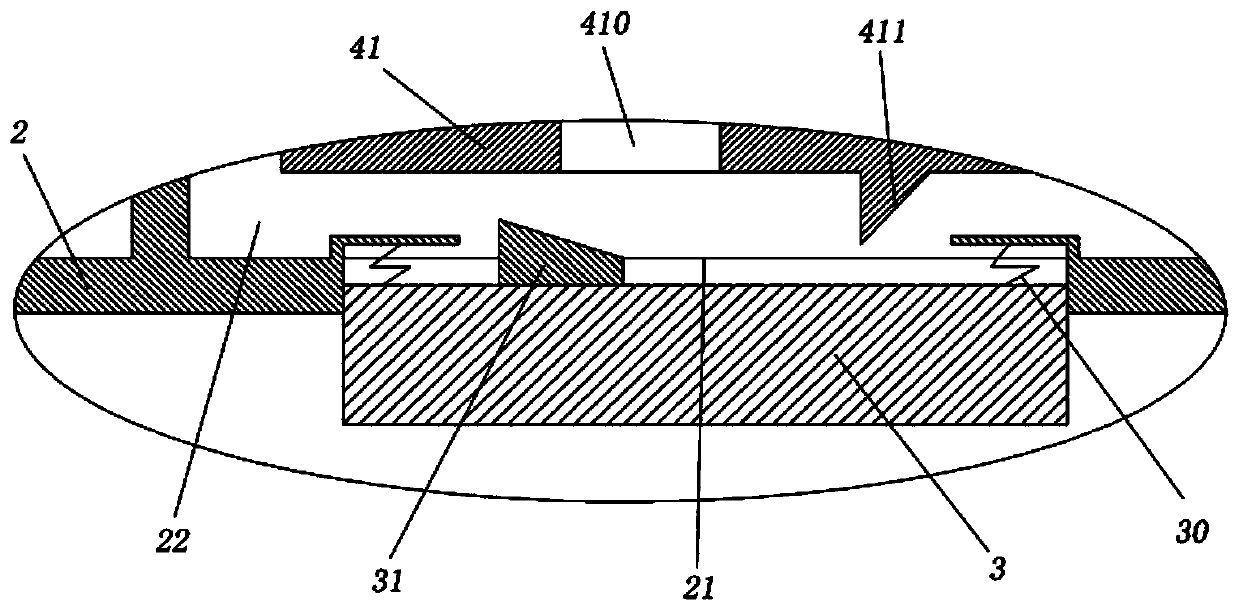

Mortar processing method

A processing method and mortar technology, which is applied in the preparation of mud mixture and the field of mortar preparation, can solve the problems affecting the quality of slurry, easy to solidify and agglomerate, and block the discharge port, so as to ensure the quality of slurry and the stability of the slurry process , the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0045] The difference between this embodiment and Example 1 is: in step A, the ingredients: by mass parts, weigh 10Kg of cement, 10Kg of construction slag powder, 6Kg of stone powder, 3Kg of gypsum powder, 4Kg of fly ash, and 0.7Kg of binder , 15Kg of water.

Embodiment 3

[0047] The difference between this embodiment and Example 1 is: in step A, the ingredients: by mass parts, weigh cement 5-15Kg, construction slag powder 15Kg, stone powder 8Kg, gypsum powder 4Kg, fly ash 5Kg, binding agent 1Kg, water 20Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com