Water preparation technology of metasilicic acid-enriched low-scale mineral water

A mineral water, silicic acid type technology, applied in water/sewage treatment, heating water/sewage treatment, light water/sewage treatment, etc., to achieve the effect of strong product adaptability, quality safety, taste and appearance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

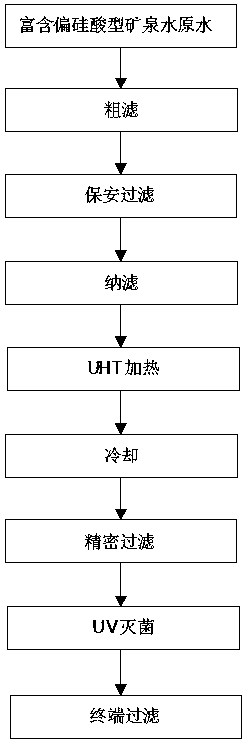

[0028] as attached figure 1 As shown, a kind of metasilicate-rich low-scaling mineral water water production process of the present invention improves the raw water selection and production process. The raw water is selected from high-hardness natural drinking mineral water rich in metasilicate. The production process of scale mineral water is as follows: raw water is taken from deep well, coarse filtration, security filtration, nanofiltration, UHT heating, cooling, fine filtration, UV sterilization, and terminal filtration to form low scale mineral water. The produced water can be filled into packaged drinking water, and can also be used as a direct drinking water pipeline to enter the household.

[0029] in,

[0030] The raw water is pumped from deep groundwater by the deep well pump in the purification well room and supplied to the raw water tank.

[0031] The coarse filtration process selects anthracite, manganese sand, 0.5-1 quartz sand, 1-2 quartz sand, 2-4 quartz sand...

Embodiment 2

[0041] as attached figure 1 As shown, the present invention is a water production process of metasilicate-rich low-scale mineral water, which improves the raw water selection and production process. The raw water is selected from high-hardness natural drinking mineral water rich in strontium and metasilicate. The low-scale mineral water production process is as follows: the raw water is taken from deep wells, coarsely filtered, security filtered, nano-filtered, UHT heated, cooled, finely filtered, UV sterilized, and terminally filtered to form low-scale mineral water. The produced water can be filled into packaged drinking water, and can also be used as a direct drinking water pipeline to enter the household.

[0042] in,

[0043] The raw water is pumped from deep groundwater by the deep well pump in the purification well room and supplied to the raw water tank.

[0044] The coarse filtration process selects anthracite, manganese sand, 0.5-1 quartz sand, 1-2 quartz sand, 2-4...

Embodiment 3

[0054] as attached figure 1 As shown, the present invention is a water production process of low-scale mineral water rich in metasilicate, which improves the selection of raw water and production process. The raw water is selected from natural drinking mineral water with low hardness rich in metasilicate. The production process of scale mineral water is as follows: raw water is taken from deep well, coarse filtration, security filtration, nanofiltration, UHT heating, cooling, fine filtration, UV sterilization, and terminal filtration to form low scale mineral water. The produced water can be filled into packaged drinking water, and can also be used as a direct drinking water pipeline to enter the household.

[0055] in,

[0056] The raw water is pumped from deep groundwater by the deep well pump in the purification well room and supplied to the raw water tank.

[0057] The coarse filtration process selects anthracite, manganese sand, 0.5-1 quartz sand, 1-2 quartz sand, 2-4 q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com