Catalytic cracking oil refining device based on coupling of microwaves with ultrasonic waves

An oil refining unit and catalytic cracking technology, which is applied in the chemical/physical/physical chemical process of applying energy, the petroleum industry, and the treatment of hydrocarbon oil, etc. It can solve the problem of insufficient penetration depth of microwave radiation, limit the application of microwave technology, and affect the microwave radiation of device volume Uniformity and other issues, to achieve the effect of good oil refining, low refining cost, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

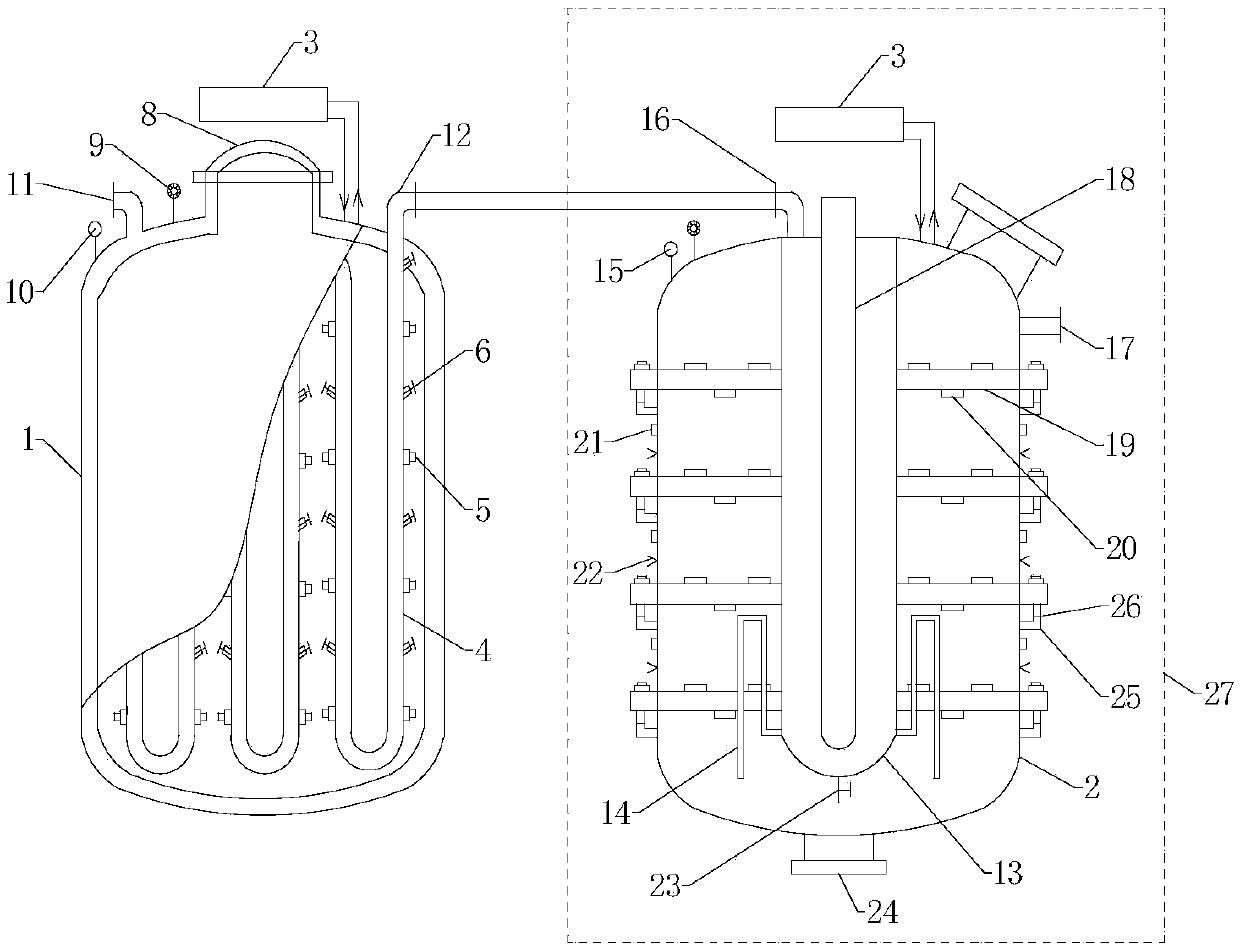

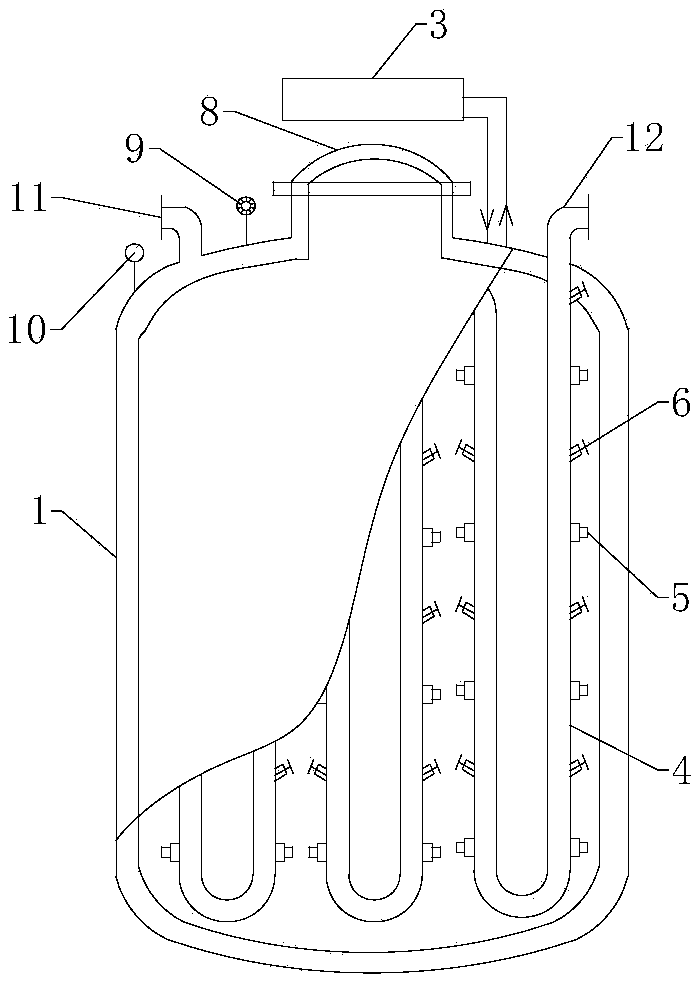

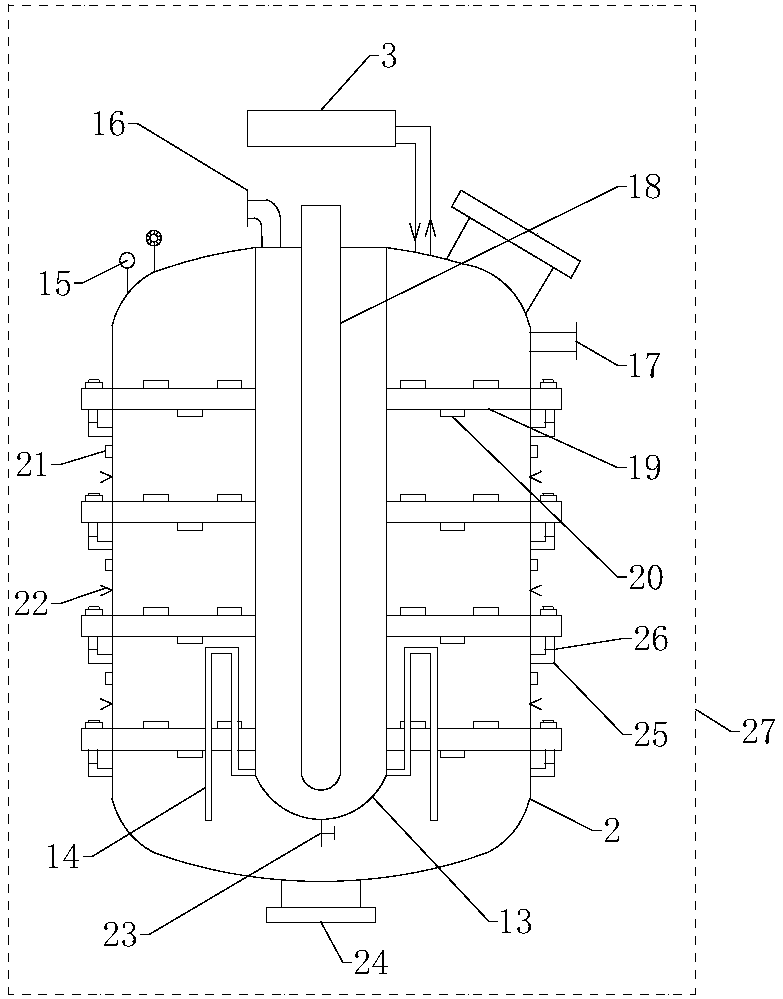

[0022] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-5 Shown: the present invention provides a kind of microwave-coupled ultrasonic catalytic cracking oil refinery unit, comprises vacuum reactor 1, separation kettle 2 and is used for the circulating cooling device 3 that vacuum reactor and separation kettle are cooled, and vacuum reactor refers to reactor The kettle body is a sandwich structure, including an inner kettle body and an outer kettle body. A vacuum cavity is formed between the inner and outer kettle bodies to isolate ultrasonic waves, protect the health of operators and avoid ultrasonic pollution. The reactor body is integrally formed or made of multi-layer The reactor body is spliced together. The reactor body is made of 304 stainless steel. There is a U-shaped tubular resonant cavity 4 inside the vacuum reactor. A microwave generator 5 and an ultrasonic generator 6, the top of the resonant cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com