Light high-intensity electromagnetic windshield glass and manufacturing method thereof

An electromagnetic shielding and windshield technology, applied in the fields of magnetic field/electric field shielding, electrical components, coatings, etc., can solve the problems of difficulty in implementation, reduced resistance and strength of electromagnetic shielding films, and achieves high light transmittance requirements. High light rate, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation steps of the electromagnetic shielding windshield are:

[0026] (1) Wash and dry the surface layer 1, put it into a chemical strengthening furnace for chemical strengthening, after the strengthening is completed, take out the surface layer 1, clean and dry;

[0027] (2) adopting the method for magnetron sputtering to plate an electric heating film layer 2 on the surface of the surface layer 1, the square resistance of the electric heating film layer 2 is controlled at 5-10Ω / □;

[0028] (3) After the electric heating film layer 2 is plated, the electrode layer 10 is plated on the electric heating film layer 2, and the electrode layer 10 width is 10mm;

[0029] (4) The electromagnetic shielding layer 4 is prepared on the surface of the inner layer 5. The specific preparation method is as follows: first, a metal film is plated on the inner layer 5, and then the micro-nano grid structure is etched on the metal film. The line width is 0.5-15μm, and the grid ...

Embodiment 1

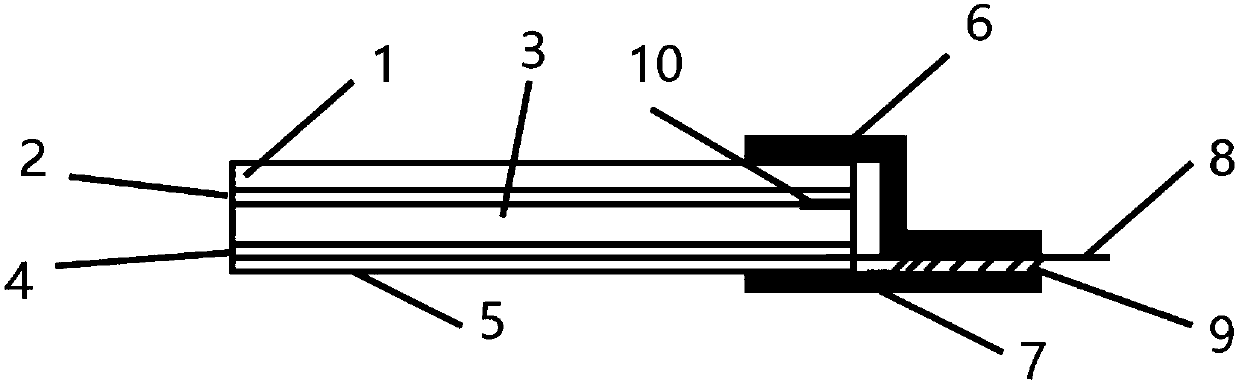

[0033] The electromagnetic shielding windshield consists of 10 parts. The first part is the surface layer, the second part is the electric heating film layer, the third part is the middle adhesive layer, the fourth part is the electromagnetic shielding layer, the fifth part is the inner layer, the sixth part is the upper frame, and the seventh part It is the lower frame, the 8th part is the electrical connection lead-out layer, the 9th part is the adhesive layer, and the 10th part is the electrode layer.

[0034] The surface layer 1 is made of chemically strengthened aluminosilicate glass, the electric heating film layer 2 is made of indium tin oxide (ITO) film, and the electric heating film layer 2 is prepared on the surface layer 1 by magnetron sputtering. The middle adhesive layer 3 is made of polyurethane, the electromagnetic shielding layer 4 is a metal micro-nano grid structure, the inner layer 5 is made of PET, the upper frame 6 and the lower frame 7 are carbon fiber re...

Embodiment 2

[0044] The electromagnetic shielding windshield consists of 10 parts. The first part is the surface layer, the second part is the electric heating film layer, the third part is the middle adhesive layer, the fourth part is the electromagnetic shielding layer, the fifth part is the inner layer, the sixth part is the upper frame, and the seventh part It is the lower frame, the 8th part is the electrical connection lead-out layer, the 9th part is the adhesive layer, and the 10th part is the electrode layer.

[0045] The surface layer 1 is made of chemically strengthened aluminosilicate glass, the electric heating film layer 2 is made of indium tin oxide (ITO) film, and the electric heating film layer 2 is prepared on the surface layer 1 by magnetron sputtering. The intermediate adhesive layer 3 is made of polyurethane, the electromagnetic shielding layer 4 is a metal micro-nano grid structure, the inner layer 5 is made of ultra-thin flexible glass, the upper frame 6 and the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com