Double-layer composite refractory material, double-layer composite refractory material ditch cover, manufacture method for ditch cover, and application of material

A refractory, double-layer composite technology, applied in the field of metallurgy, can solve the problems of easy falling off, high strength and rigidity, easy to be subjected to strong impact, etc., and achieves good thermal insulation effect, good thermal shock resistance, and pollution reduction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

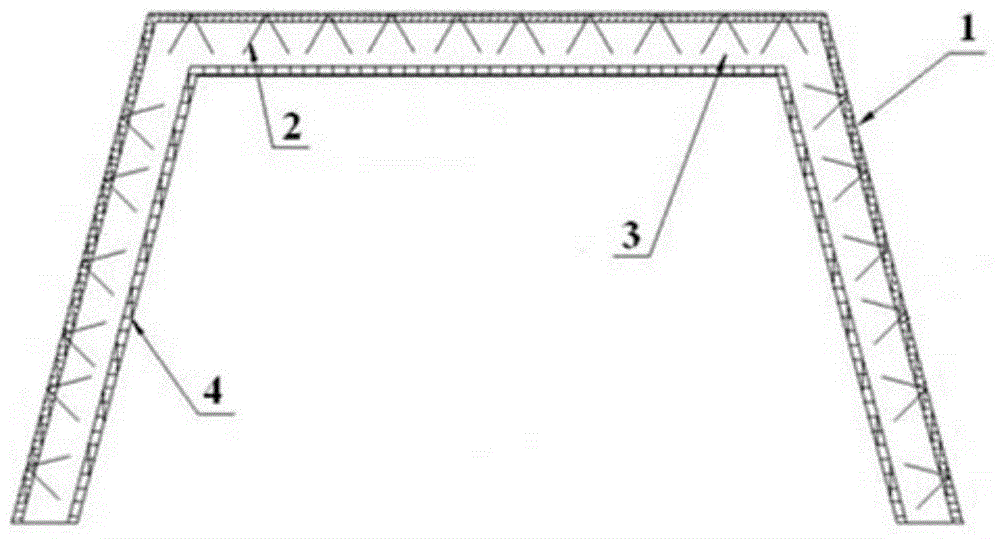

[0023] Such as figure 1 As shown, it is a double-layer composite refractory ditch cover for an iron gutter of an ironmaking blast furnace provided by an embodiment of the present invention. The trench cover includes a steel structure shell 1 , a main refractory material layer 3 filled in the steel structure shell 1 , and an anti-hot metal scour layer 4 arranged on the inner and outer surfaces of the steel structure shell 1 . A plurality of umbrella-shaped reinforcing ribs 2 are also connected to the outer inner surface of the steel structure shell 1 . The thickness of the main refractory material layer 3 is 10-15 cm, and the thickness of the anti-flushing layer 4 is 2-5 mm. The cross section of the ditch cover is trapezoidal, and the sample size is 5.5m long*(bottom width 2m, top width 1.5m)*high 1.3m.

[0024] In this embodiment, the composition of the main refractory material layer 3 is (in parts by weight): 1 part of ceramsite, 0.67 part of floating beads, 0.05 part of pe...

Embodiment 2

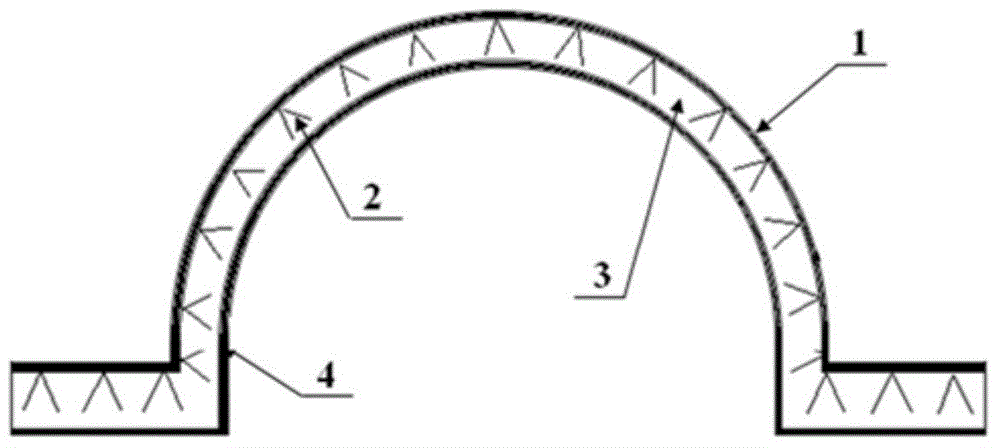

[0029] Such as figure 2 As shown, it is a double-layer composite refractory ditch cover for an iron gutter of an ironmaking blast furnace provided by an embodiment of the present invention. The cross-section of the double-layer composite refractory trench cover is arc-shaped, and the size is 5.5m*(bottom width: 2m, arc top radius: 1m)*height: 1.3m.

[0030] In this embodiment, the composition of the main refractory material layer 3 is (by weight): 1.5 parts of ceramsite, 1 part of floating beads, 0.1 part of perlite, 1.5 parts of calcium aluminate cement (CA-50), 0.05 parts of steel fiber, 0.55 parts of water, 0.012 parts of water reducing agent. Pour the lightweight refractory castable into the concrete mixer, add water and mix evenly until the castable just segregates.

[0031] In the present embodiment, the composition of the anti-hot metal scour layer 4 is (in parts by weight): 20 parts of concentrated phosphoric acid, 8 to 8.5 parts of water, Al(OH) 3 5 parts of fine ...

Embodiment 3

[0035] An embodiment of the present invention provides a double-layer composite refractory ditch cover for an iron ditch of an iron-making blast furnace. The cross-section of the ditch cover is rectangular, and the size is 5.5m long * 2m wide at the bottom * 0.15m high.

[0036] In this embodiment, the composition of the light and high-strength main body layer is (in parts by weight): 1 part of ceramsite, 0.67 part of floating beads, 0.05 part of perlite, 1.2 parts of calcium aluminate cement (CA-50), 0.02 part of steel fiber, water 0.38 parts, 0.01 parts of water reducing agent. Pour the lightweight refractory castable into the concrete mixer, add water and mix evenly until the castable just segregates.

[0037]In this embodiment, the composition of the wear-resistant and anti-scouring surface layer is (in parts by weight): 20 parts of phosphoric acid, 8 to 8.5 parts of water, Al(OH) 3 5 parts of fine powder, 0.35 parts of aluminum silicate fiber, α-Al 2 o 3 22 parts of fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com