Laminated production method of channel plate

A grooved plate and lamination technology, applied in the direction of manufacturing tools, ceramic molding machines, mold auxiliary parts, etc., can solve the problems of increasing labor intensity and workload, large plant floor area, unfavorable large-scale production, etc. The effect of production and construction speed, small footprint, and simplified fixed workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the drawings and embodiments:

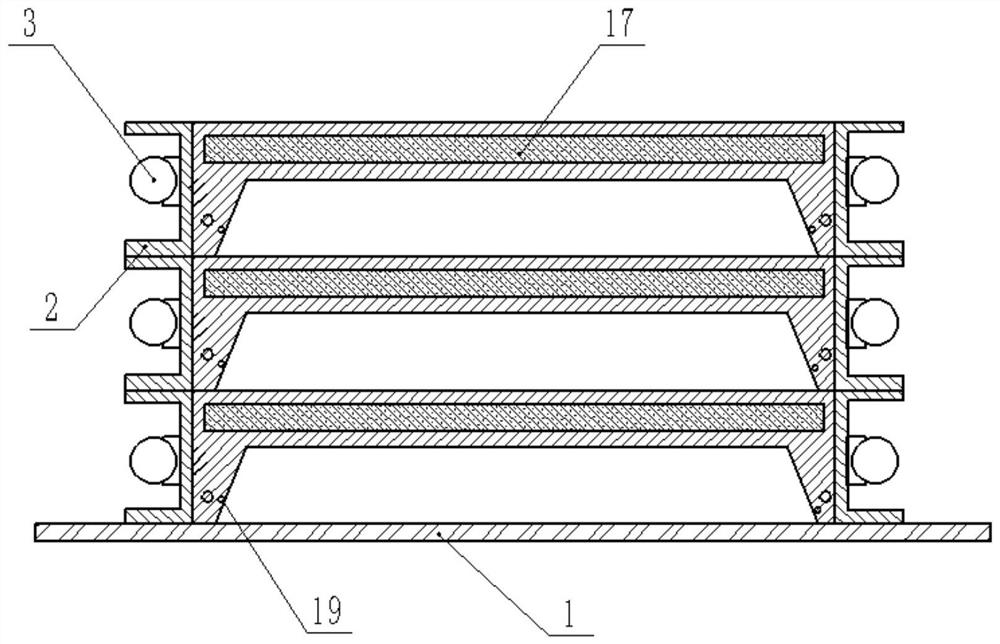

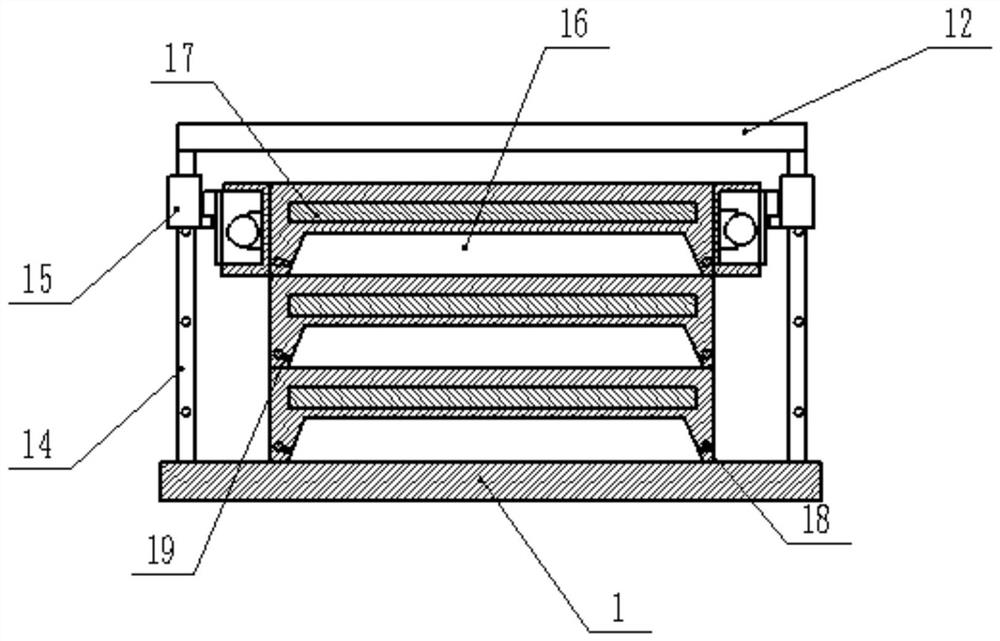

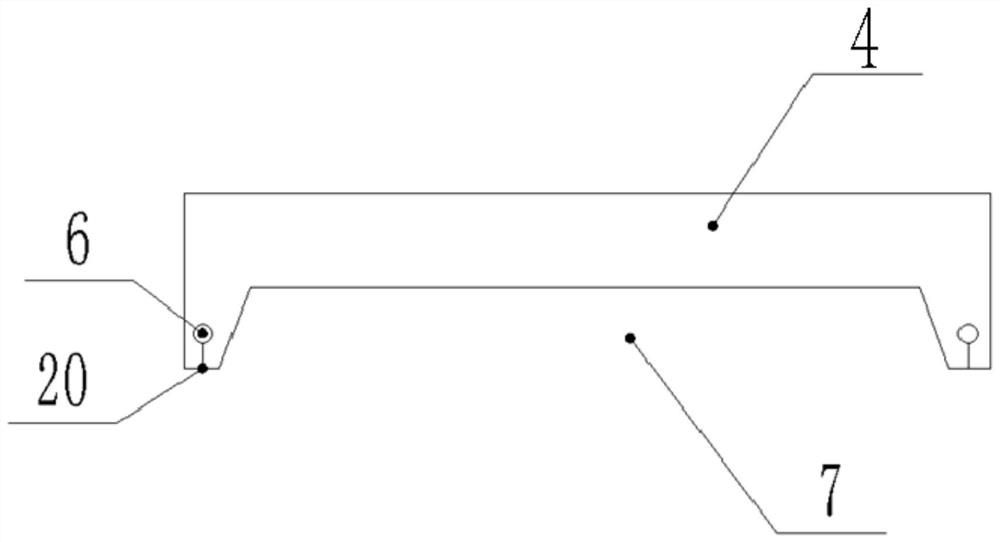

[0046] See Figure 1 to Figure 5 The laminated manufacturing method of a trough-shaped plate shown includes the following steps:

[0047] (1) Clean the ground mold 1 and prepare the side mold 2 and pre-stressed anchors; by cleaning the ground mold 1 to prevent foreign matter from being mixed into the trough plate, the strength and flatness of the bottom surface of the trough plate are affected. influences.

[0048] (2) Brush the release agent or cover the isolation film on the upper surface of the ground mold 1 and the inner side of the side mold 2; by brushing the release agent or cover the isolation film on the upper surface of the ground mold 1 and the inner side of the side mold 2, so that The grooved plate is easier to demold, and due to the setting of the isolation film, the smoothness of the bottom surface of the grooved plate is further increased.

[0049] (3) Str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com