High-pressure biogas slurry discharger

A discharger and high-pressure technology, applied in the field of high-pressure biogas liquid discharge agitator, can solve the problems affecting the development of biogas industry, unsatisfactory effect, laborious and other problems, and achieve the improvement of liquid discharge efficiency, simple structure, and increased gas production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

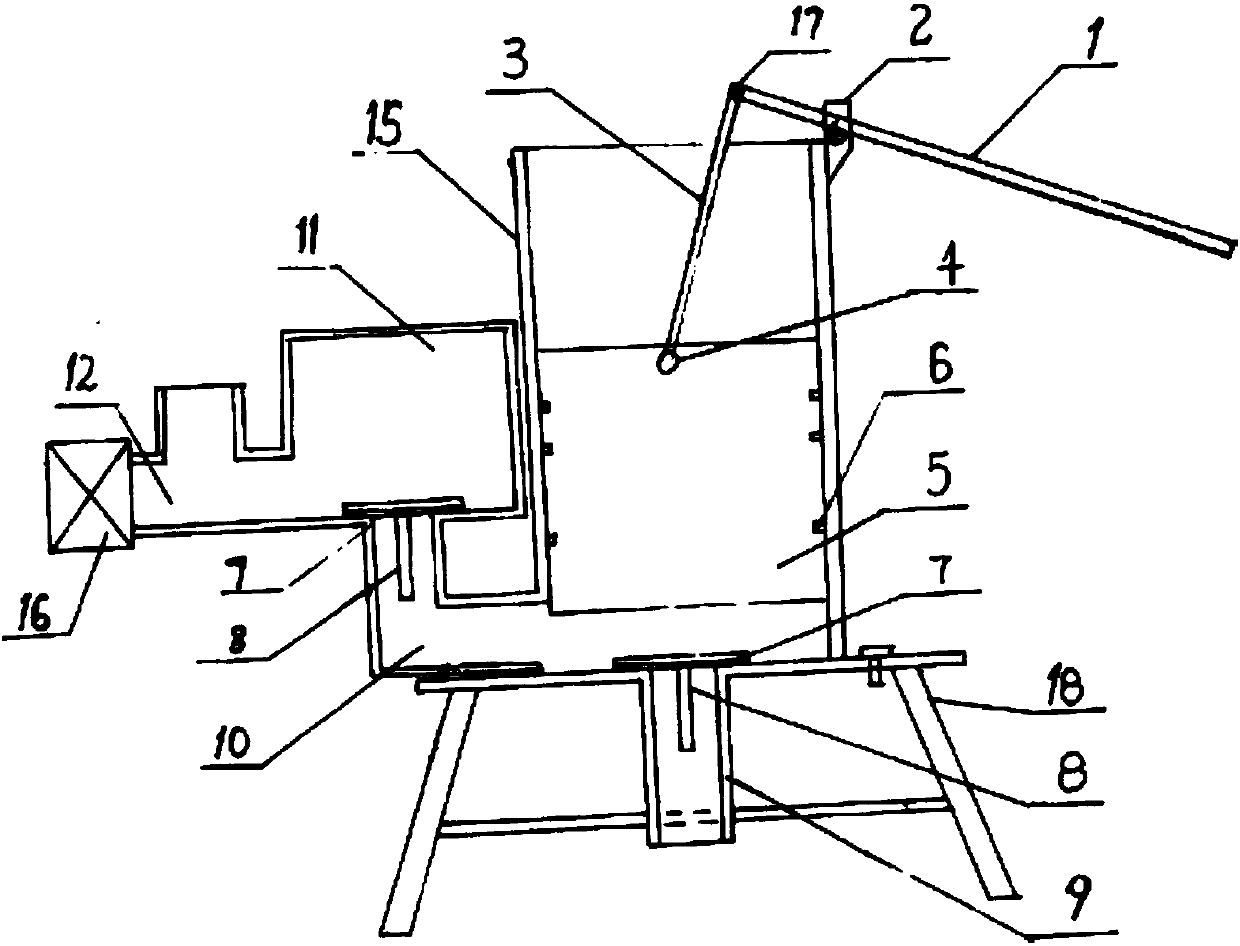

[0007] Below in conjunction with accompanying drawing, the present invention is described in further detail: select the whole set of cylinder liner, piston, piston ring, piston pin of 195 diesel engines for use, assemble as it is, weld the upper fulcrum on the upper edge of the cylinder liner, use a steel pipe with a diameter of 20MM Make the movable connection between the handle and the fulcrum, use the steel bar with a diameter of 12MM as the connecting rod, one end is connected with the piston pin, and the other end is connected with the handle. After welding the water inlet pipe at the bottom of the cylinder liner, put an appropriate size flat gasket and positioning pin at the joint, then connect the connecting pipe on the bottom side of the cylinder liner, and connect the high-pressure tank to the other end of the connecting pipe. The connection with the connecting pipe is provided with a flat gasket and a positioning pin, and the supporting valve is fixed on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com