Method for primary pulp pulping of paper making

A technology for pulp and wood pulp, applied in the field of household paper, can solve the problems such as difficulty in improving the beating degree of softwood pulp and insignificant improvement effect, and achieve the effects of improving water drainage, reducing energy consumption and reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

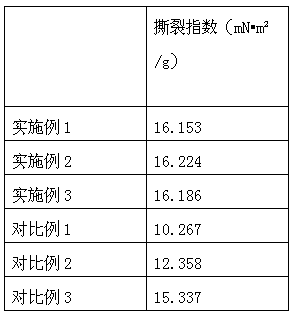

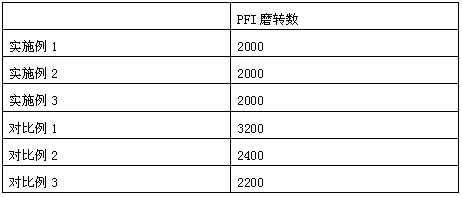

Embodiment 1

[0018] A method for beating raw pulp for papermaking, the raw pulp raw material is mixed wood pulp obtained by mixing 80% hardwood pulp and 20% softwood pulp, and the beating method comprises the following steps:

[0019] (1) Disintegrate the mixed wood pulp with a hydraulic pulper, and then stir it at a speed of 2000r / min for 40min to obtain the disintegrated pulp;

[0020] (2) Add hemicellulase to the decomposed slurry, heat the slurry to 30°C, then adjust the pH of the slurry to 5.5, treat for 5 hours, and then add the enzymatically hydrolyzed slurry to the vacuum reaction Treat in the kettle for 10 minutes, the treatment temperature is 90°C, then take it out, and cool it down to room temperature naturally to obtain the pretreated slurry;

[0021] (3) Add sodium alginate-modified attapulgite with a mass of 0.15% to the pretreatment slurry obtained in step (2), adjust the concentration of the pretreatment slurry to 10%, and then beat it through a PFI refiner for 2000 change...

Embodiment 2

[0030] A method for beating raw pulp for papermaking, the raw pulp raw material is mixed wood pulp obtained by mixing 80% hardwood pulp and 20% softwood pulp, and the beating method comprises the following steps:

[0031] (1) Disintegrate the mixed wood pulp with a hydraulic pulper, and then stir it at a speed of 2500r / min for 40min to obtain the disintegrated pulp;

[0032] (2) Add hemicellulase to the decomposed slurry, heat the slurry to 30-35°C, then adjust the pH of the slurry to 6.0, treat for 8 hours, and then add the enzymatically hydrolyzed slurry to Treat in a vacuum reactor for 15 minutes at a temperature of 100°C, then take it out, and cool it down to room temperature naturally to obtain a pretreated slurry;

[0033] (3) Add 0.3% of the mass of sodium alginate modified attapulgite to the pretreatment slurry obtained in step (2), adjust the concentration of the pretreatment slurry to 10%, and then beat it through a PFI refiner for 2400 change.

[0034] Further, th...

Embodiment 3

[0042] A method for beating raw pulp for papermaking. The raw pulp raw material is mixed wood pulp obtained by mixing 80% hardwood pulp and 20% softwood pulp. The beating method comprises the following steps:

[0043] (1) Decompose the mixed wood pulp with a hydraulic pulper, and then stir it at a speed of 2200r / min for 40min to obtain the decomposed pulp;

[0044] (2) Add hemicellulase to the decomposed slurry, heat the slurry to 33°C, then adjust the pH of the slurry to 5.8, treat for 6 hours, and then add the enzymatically hydrolyzed slurry to the vacuum reaction Treat in the kettle for 10-15min at a temperature of 90-100°C, then take it out and cool it down to room temperature naturally to obtain the pretreated slurry;

[0045] (3) Add 0.2% of the mass of sodium alginate modified attapulgite to the pretreatment slurry obtained in step (2), adjust the concentration of the pretreatment slurry to 10%, and then beat it through a PFI refiner for 2200 change.

[0046] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com