Three-dimensional porous sheet ferroferric oxide/carbon nanometer electromagnetic wave absorption material and preparing method thereof

A technology of ferroferric oxide and absorbing materials, which is applied in the directions of magnetic materials, inorganic material magnetism, magnetic field/electric field shielding, etc., can solve the problems of low reflection loss intensity, achieve low production cost, improve electromagnetic wave absorption performance, and high magnetic permeability rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

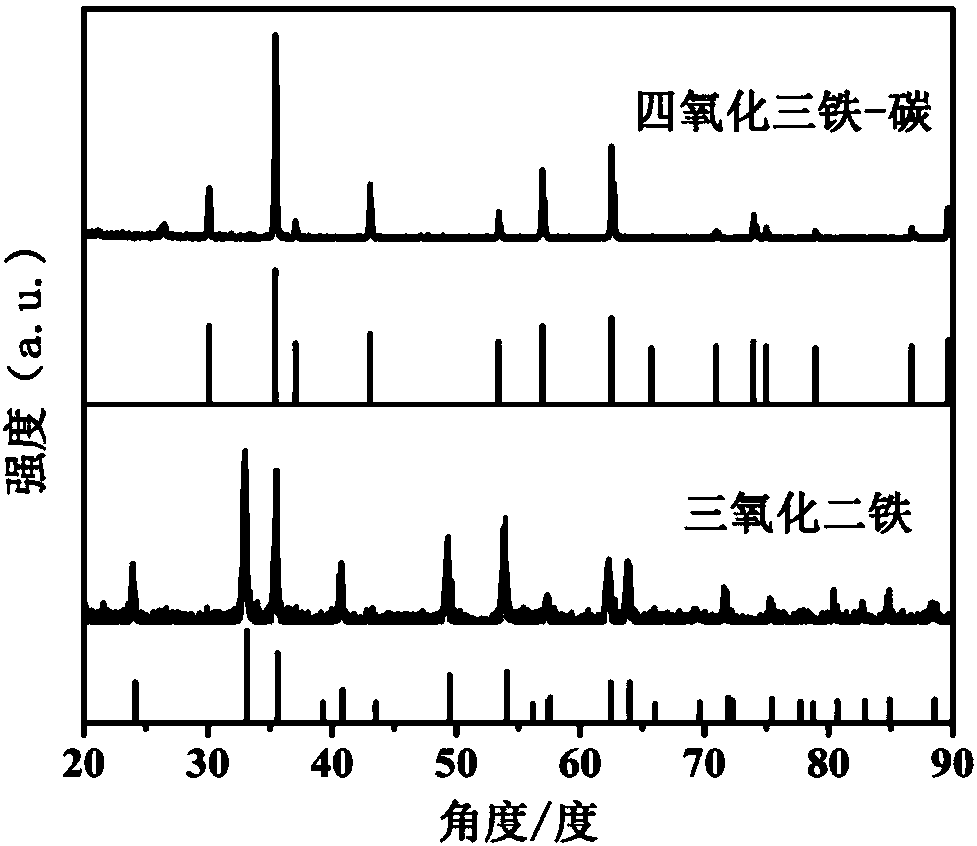

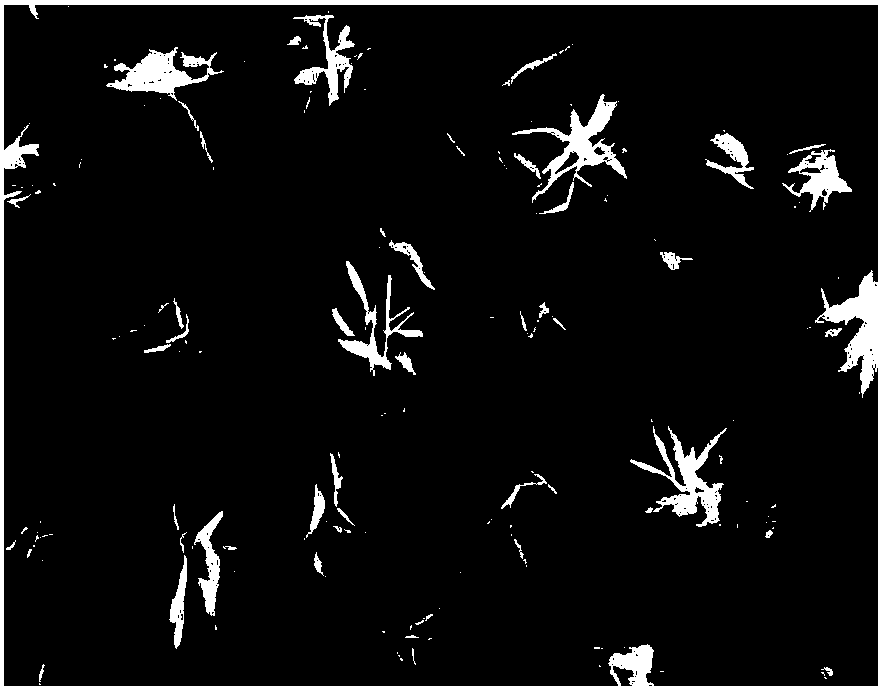

[0054] A method for preparing a three-dimensional porous lamellar Fe3O4 / carbon nanometer electromagnetic wave absorbing material, comprising the following steps:

[0055] 1) FeCl 3 ·6H 2 O, urea is as the precursor of synthesizing ferric oxide, and polyvinylpyrrolidone is as surfactant, adds in the 100mL ethylene glycol solvent by mass ratio 3:4:4, and in airtight reactor, reacts 10h under 180 ℃, After the reaction is completed, the product is washed and dried to obtain iron oxyhydroxide; the prepared iron oxyhydroxide is calcined at 350°C for 3 hours to obtain ferric oxide powder;

[0056] 2) Mix 1.5g of ferric oxide powder in step 1) with 0.5g of pyrrole, and then react in a closed reaction kettle at 550°C for 5h to obtain a three-dimensional porous lamellar ferric oxide / carbon nano Electromagnetic wave absorbing material.

[0057] The TG test was carried out on the electromagnetic wave absorbing material prepared in this embodiment, and the mass percentages of carbon and...

Embodiment 2

[0065] A method for preparing a three-dimensional porous lamellar Fe3O4 / carbon nanometer electromagnetic wave absorbing material, comprising the following steps:

[0066] 1) Fe(NO 3 ) 3 9H 2 O, urea is as the precursor of synthesizing ferric oxide, and polyvinylpyrrolidone is as surfactant, adds in 100mL ethylene glycol solvents by mass ratio 3:4:2, and in airtight reactor, reacts 30h under 100 ℃, After the reaction is completed, the product is washed and dried to obtain iron oxyhydroxide; the prepared iron oxyhydroxide is calcined at 300°C for 5 hours to obtain ferric oxide powder;

[0067] 2) Mix 2g of ferric oxide powder in step 1) with 1g of pyrrole, and then react in a closed reaction kettle at 500°C for 30h to obtain a three-dimensional porous layered ferric oxide / carbon nanometer electromagnetic wave absorber Material.

[0068] The TG test was carried out on the electromagnetic wave absorbing material prepared in this embodiment, and the mass percentages of carbon a...

Embodiment 3

[0072] A method for preparing a three-dimensional porous lamellar Fe3O4 / carbon nanometer electromagnetic wave absorbing material, comprising the following steps:

[0073] 1) Fe(NO 3 ) 3 9H 2 O, urea is used as the precursor of synthesizing ferroferric oxide, and polyvinylpyrrolidone is used as surfactant, adds in 100mL ethylene glycol solvents by mass ratio 1:3:0.5, and in airtight reactor, reacts 2h under 400 ℃, After the reaction is completed, the product is washed and dried to obtain iron oxyhydroxide; the obtained iron oxyhydroxide is calcined at 500°C for 1 hour to obtain ferric oxide powder;

[0074] 2) Take 4g of ferric oxide powder in step 1) and mix with 1g of pyrrole, and then react in a closed reaction kettle at 600°C for 2h to obtain a three-dimensional porous lamellar ferric oxide / carbon nanometer electromagnetic wave absorption Material.

[0075]The TG test was carried out on the electromagnetic wave absorbing material prepared in this embodiment, and the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com