Preparation method of catalytic cracking catalyst for maximizing isomeric low-carbon olefin production

A low-carbon olefin and catalytic cracking technology, which is applied in the direction of catalyst activation/preparation, catalytic cracking, physical/chemical process catalysts, etc., and can solve the problem of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) 440g of Beta molecular sieve is beaten with water, 14.8g of 85% phosphoric acid and 20ml of ferric chloride solution are added for modification, the slurry is filtered, and the filter cake is baked at 600°C for 1.5h after drying;

[0040] (2) 2.63Kg ZSM-5 molecular sieve is beaten with water, 1000ml of sodium hydroxide solution is added, the reaction temperature is controlled at 75°C, the reaction time is 1 hour, the slurry is filtered, and the filter cake is set aside;

[0041] (3) Beta, ZSM-5 molecular sieve treated in (1), (2) are beaten together with 3.86Kg kaolin, 1.29KgREUSY molecular sieve, 4.31Kg pseudo-boehmite, acidified;

[0042] (4) Spray-dry the slurry in (3) to obtain the desired catalyst, marked as YG-1.

Embodiment 2

[0044] (1) 660g of Beta molecular sieve and water beating, adding 33.3g of 85% phosphoric acid and 45ml of ferric chloride solution for modification, filtering the slurry, drying the filter cake and roasting at 600°C for 1.5h;

[0045] (2) 2.11Kg ZSM-5 molecular sieve is beaten with water, 400ml of sodium hydroxide solution is added, the reaction temperature is controlled at 75°C, the reaction time is 1 hour, the slurry is filtered, and the filter cake is set aside;

[0046] (3) Beta, ZSM-5 molecular sieve treated in (1), (2) is beaten together with 4.22Kg kaolin, 1.65KgREUSY molecular sieve, 3.85Kg pseudo-boehmite, acidified;

[0047] (4) Spray-dry the slurry in (3) to obtain the desired catalyst, marked as YG-2.

Embodiment 3

[0049] (1) 880g of Beta molecular sieve is beaten with water, 59.3g of 85% phosphoric acid and 80ml of ferric chloride solution are added for modification, the slurry is filtered, and the filter cake is baked at 600°C for 1.5h after drying;

[0050] (2) 1.58Kg ZSM-5 molecular sieve is beaten with water, 450ml of sodium hydroxide solution is added, the reaction temperature is controlled at 75°C, the reaction time is 1 hour, the slurry is filtered, and the filter cake is set aside;

[0051] (3) Beta, ZSM-5 molecular sieve treated in (1), (2) are beaten together with 4.46Kg kaolin, 2.00KgREUSY molecular sieve, 3.54Kg pseudo-boehmite, acidified;

[0052] (4) Spray-dry the slurry in (3) to obtain the desired catalyst, marked as YG-3.

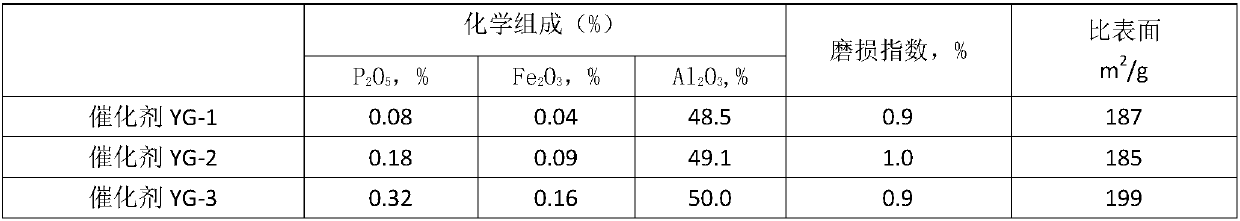

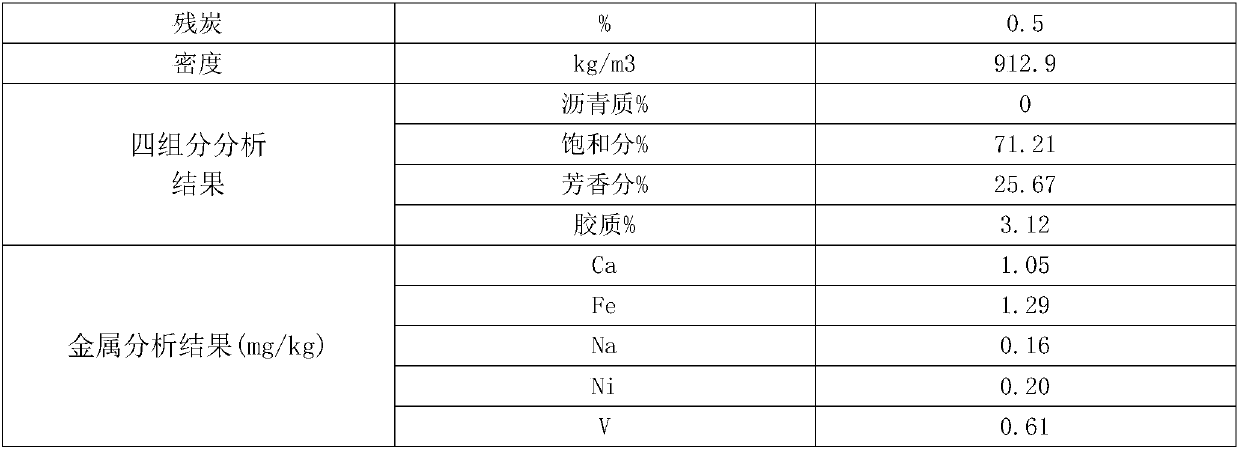

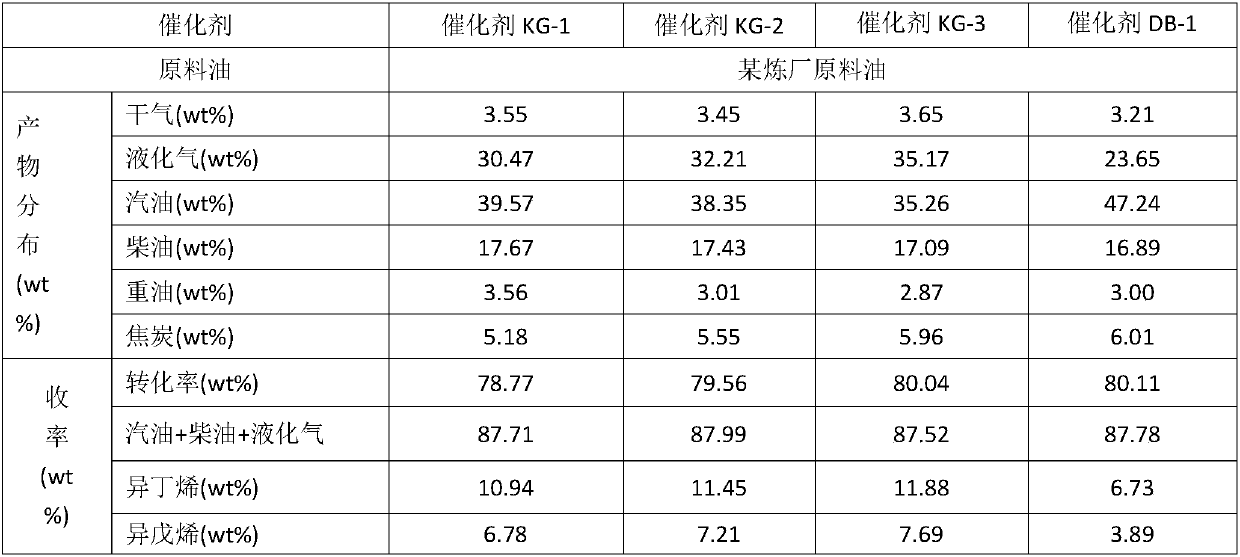

[0053] Analysis Catalyst YG-1, Catalyst YG-2, Catalyst YG-3, and Catalyst DB-1 are common catalysts that produce isoolefins produced by Huicheng Environmental Protection Technology. The analysis result of catalyst in the example is as follows

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com