Battery-free automobile tire pressure monitoring transmitter capable of freely moving in tire

A tire pressure monitoring, battery-free technology, applied in tire measurement, electric vehicles, current collectors, etc., can solve the problems of low relative wind speed, low power generation efficiency, and low current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

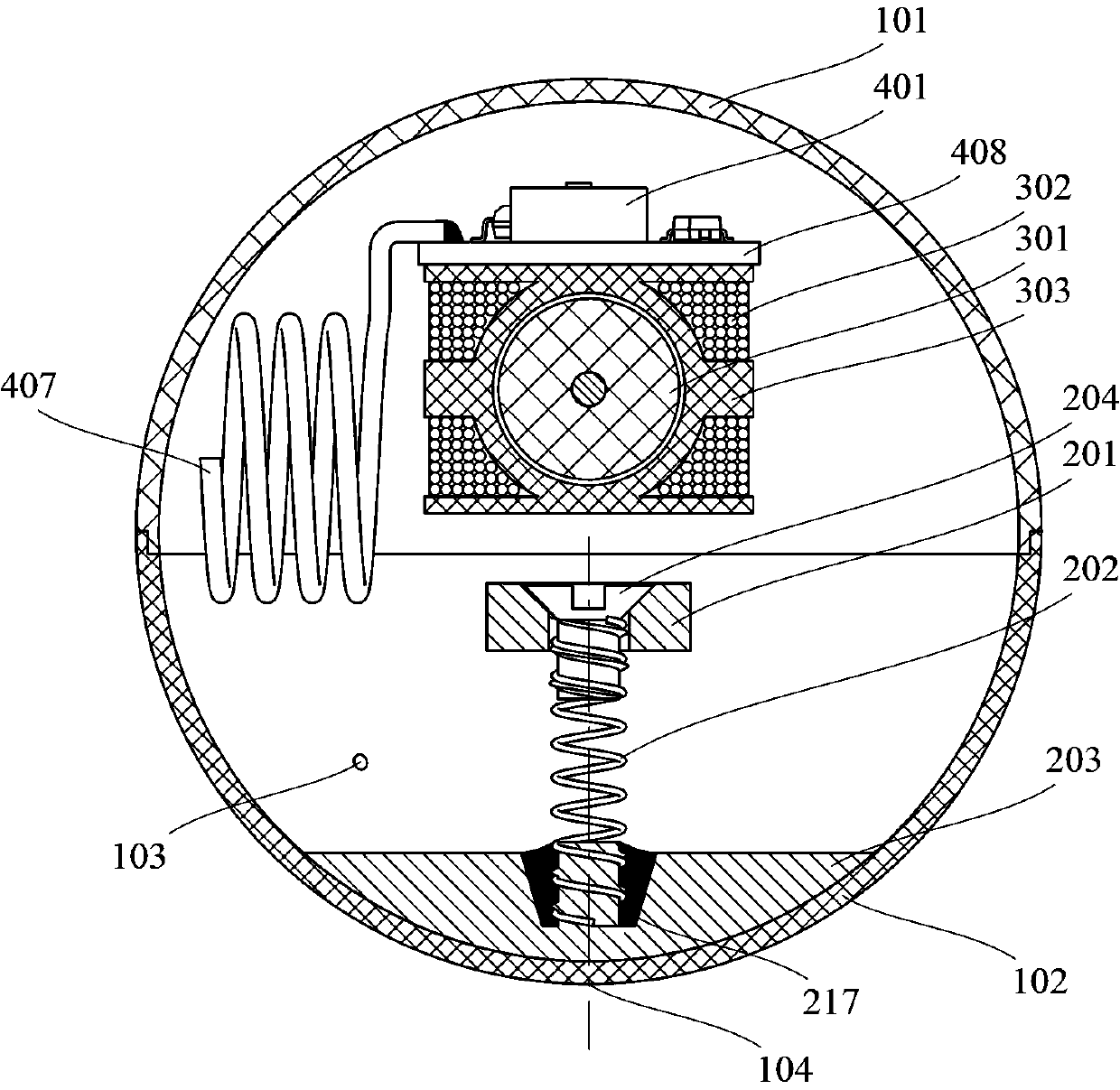

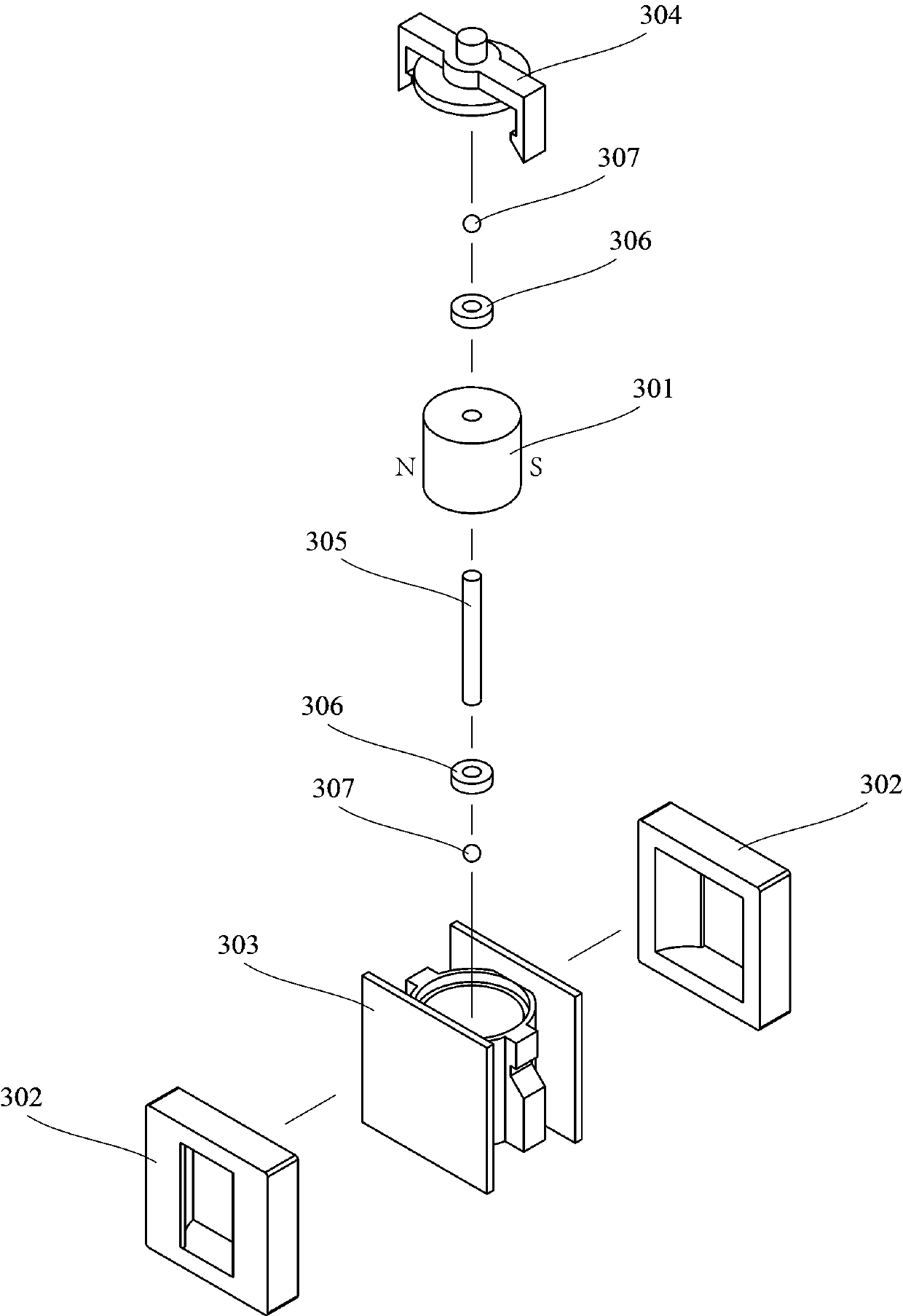

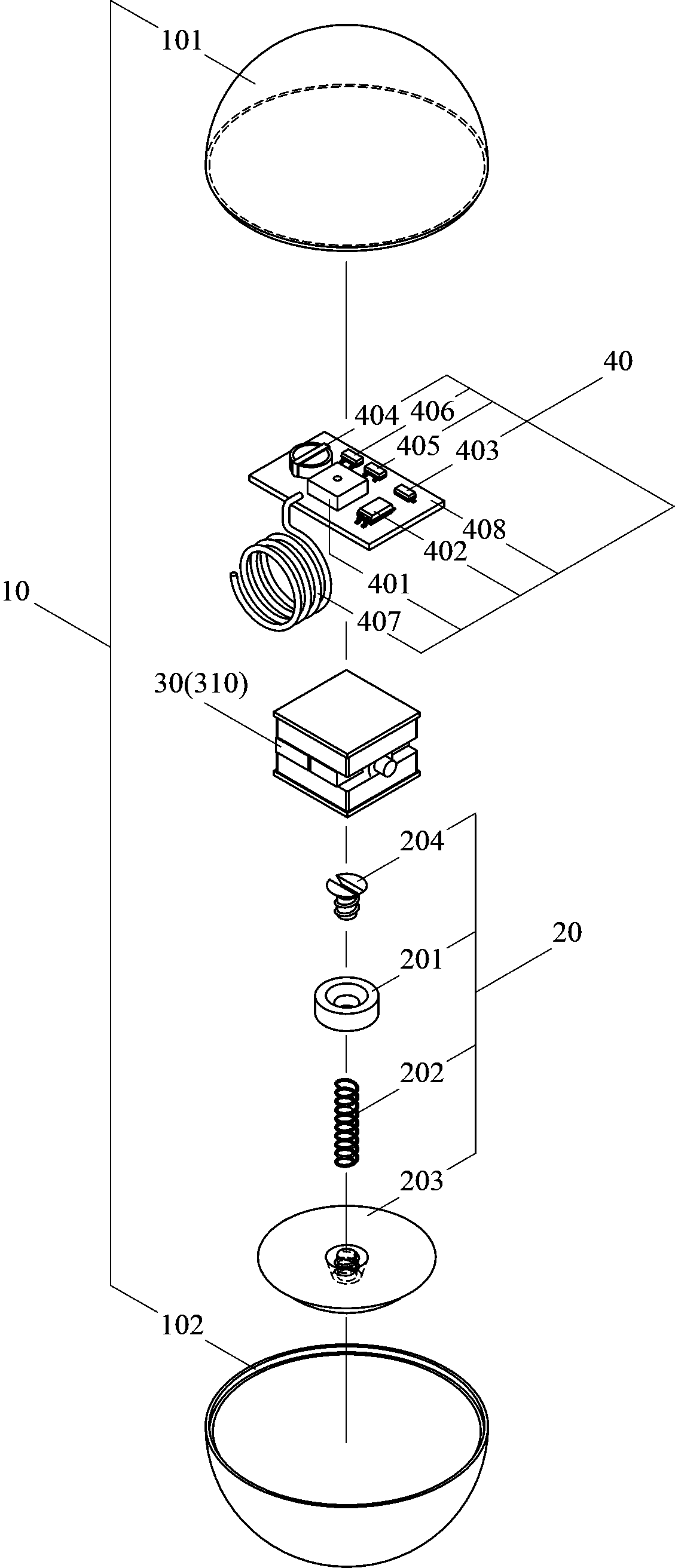

[0039] figure 1 It is a schematic cross-sectional view of this example, showing the internal structure level and connection relationship of this embodiment. refer to figure 1 , the shell 10 is formed by combining the hollow hemisphere A (101) and the hollow hemisphere B (102) through fasteners and gluing or heat-melting (assembly stage), it is noted that there is a vent hole 103 on the shell for balancing the internal and external air pressure; Inside the casing 10, from top to bottom, there are circuit boards 40 ( figure 1Only the tire pressure monitoring chip 401 and the antenna 407 welded on the PCB printed board 408 are shown in the figure. For detailed composition, please refer to image 3 ), power generating device 30 (here is an electromagnetic induction generator 310, its main components are a radially magnetized cylindrical magnetic rotor 301, an induction coil 302, and a skeleton 303, for a preferred structural detail, please refer to figure 2 ), kinetic energy h...

Embodiment 2

[0061] This embodiment has the same parts as Embodiment 1, and to avoid repetition, the same parts will not be described in detail.

[0062] Figure 5 It is a schematic cross-sectional view of this example, showing the internal structure level and connection relationship of this embodiment. refer to Figure 5 , the kinetic energy collection device of this embodiment is different from Embodiment 1, and its working principle is: when shaking kinetic energy or ground impact kinetic energy exist, utilize the pendulum that there is inertia in motion to exist motion state (position, velocity, direction) with current sphere ) difference to collect kinetic energy as the pendulum inertia energy, which will be released to the generator shaft in the form of torque. The difference is manifested as the relative rotation of the pendulum to the housing, which is amplified by the gear set and drives the generator shaft to generate electricity. The kinetic energy harvesting device 20 includ...

Embodiment 3

[0067] Likewise, the parts of this embodiment that are the same as those of Embodiment 1 will not be described again.

[0068] Figure 7 It is a schematic cross-sectional view of this example, showing the internal structure level and connection relationship of this embodiment. refer to Figure 7 , the kinetic energy harvesting device of this embodiment is different from the aforementioned embodiments. The working principle is: when there is ground impact kinetic energy, the weight of the magnet is used to compress the spring to obtain the kinetic energy as the spring compression energy, and then the magnet is bounced up by releasing the elastic force of the spring. , the linear motion of the magnet will cause the coil to cut the magnetic field lines to generate electricity. Kinetic energy acquisition device 20 comprises counterweight 213, nylon cylinder 214, spring 215, silica gel buffer pad 216 among the present example; Described power generation device comprises axial mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com