Method of using waste aged brine to prepare magnesium chloride particles

A technology of magnesium chloride wet granules and magnesium chloride, applied in magnesium chloride, magnesium halide and other directions, can solve the problems of low purity of magnesium chloride granules, complicated production process and high process cost, and achieve the effects of high recycling rate, high purity, and simple and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

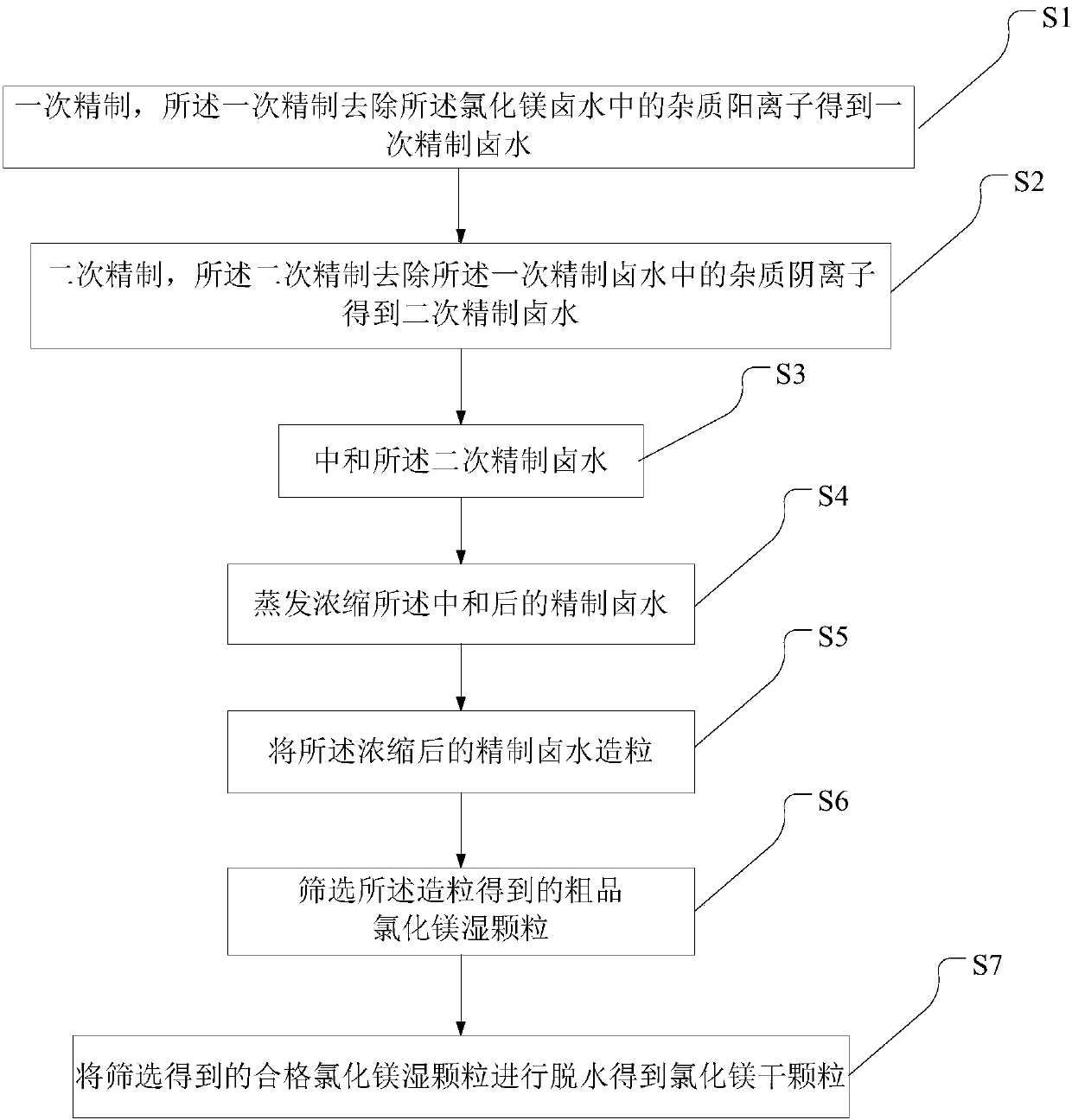

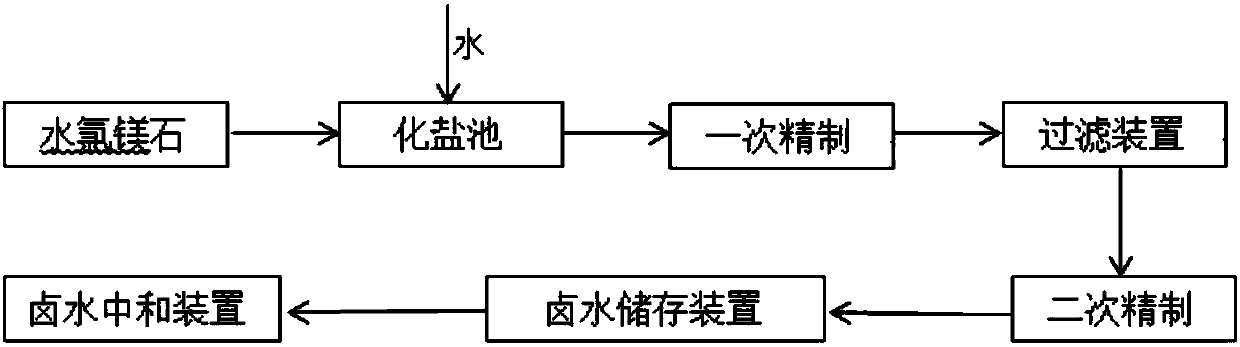

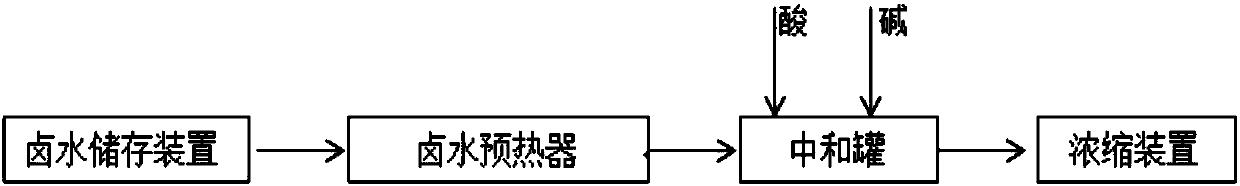

[0026] The process for preparing magnesium chloride granules from waste brine of the present invention will be described in detail below in conjunction with the accompanying drawings. see figure 1 , a kind of method for preparing magnesium chloride particle by waste old brine of the present invention comprises the following steps: S1: primary refining, removes the impurity cation in described magnesium chloride brine to obtain primary refined bittern; S2: secondary refining, removes the impurity cation in primary refined bittern; Impurity anions obtain secondary refined bittern; S3: neutralize secondary refined bittern; S4: refined bittern after evaporative concentration and neutralization; S5: granulate refined bittern after concentration; S6: wet granules of crude product magnesium chloride obtained by screening granulation ; S7: dehydrating the qualified magnesium chloride wet granules obtained by screening to obtain dry magnesium chloride granules.

[0027] It should be n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com