Humic acid activation method and device

An activation method and humic acid technology, which are applied in fertilization devices, ammonium orthophosphate fertilizers, alkaline orthophosphate fertilizers, etc., can solve the problem of low activation performance and output rate of products, long reaction time and production cycle, and poor activation effect. and other problems, to achieve good activation effect, high output rate, and the effect of promoting chlorophyll synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

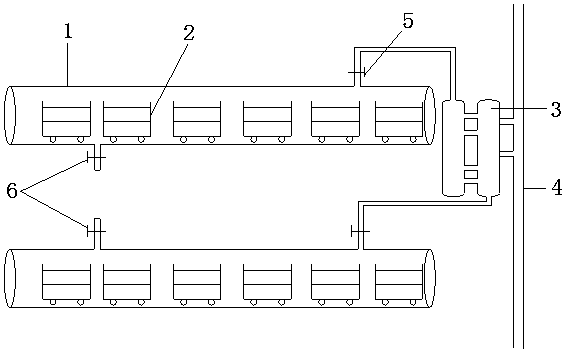

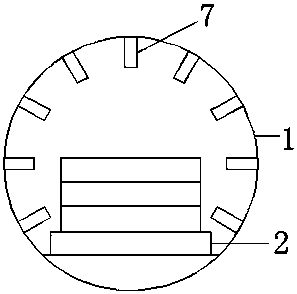

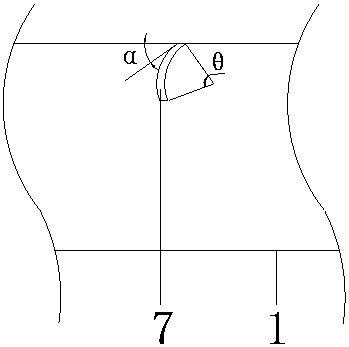

[0077] The embodiment of the present invention provides a humic acid activation device, which includes two reaction kettles 1, a steam curing car 2 and a transport traction device for moving the steam curing car 2 in the reactor 1, the transportation The traction device is connected to the steam-curing vehicle 2, the steam-curing vehicle 2 is located in the reaction kettle 1, and the steam-curing vehicle 2 is provided with a material cage for placing raw materials.

[0078]The two reaction kettles 1 are communicated with each other through a sub-cylinder 3, and a control valve 5 is respectively arranged on the communication pipeline between the two described reaction kettles 1 and the sub-cylinder 3, and the sub-cylinder 3 is communicated through a steam pipeline 4. Steam supply device. Pressure safety valves 6, steam traps, thermometers and pressure gauges are installed on the two reactors 1 to adjust and control the reaction temperature and reaction pressure of the materials...

Embodiment 2

[0085] Based on the above-mentioned humic acid activation device, the humic acid activation method provided in this embodiment is:

[0086] Mix humic acid raw materials, oxidants and activators at a weight ratio of 1:0.05:0.05 to obtain a mixture. Stir the mixture and water evenly at a weight ratio of 1:0.2 and place it in a room with a temperature of 200°C and a pressure of 1.5MPa. Steaming and reacting under saturated water vapor for 2 hours; then cooling, drying and crushing to obtain active humic acid.

[0087] The described humic acid activation method is applied to the above-mentioned device, and the specific implementation steps are:

[0088] (1) Mix the humic acid raw material, oxidizing agent and activator at a weight ratio of 1:0.05:0.05 to obtain a mixture, mix the mixture and water evenly at a weight ratio of 1:0.2, and then put them into each material cage, Code is put on the steam maintenance car 2.

[0089] (2) Transport the steaming vehicles 2 in step (1) to ...

Embodiment 3

[0096] The humic acid activation device provided in this embodiment is the same as the above-mentioned embodiment 2, the difference is that the humic acid activation method in this embodiment is:

[0097] Mix the humic acid raw material, oxidizing agent and alkalizing agent in a weight ratio of 1:0.2:0.2 to obtain a mixture, then stir the mixture and water evenly in a weight ratio of 1:0.5 and place it at a temperature of 170°C and a pressure of Under 0.8MPa saturated water vapor, it was steamed and reacted for 5 hours; then cooled, dried and pulverized to obtain active humic acid. The specific implementation steps of applying the humic acid activation method to the humic acid activation device are the same as the above-mentioned embodiments.

[0098] In the products obtained in this example, the activated humic acid content is 80% to 98%, and the activation degree is greater than or equal to 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com