Adhesion resin for multilayer co-extrusion hoses and method for preparing adhesion resin

A bonding resin and multi-layer co-extrusion technology, applied in the field of bonding resin, can solve the problems of lack of heat resistance and high cost, and achieve the effects of low cost, easy processing and high barrier property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

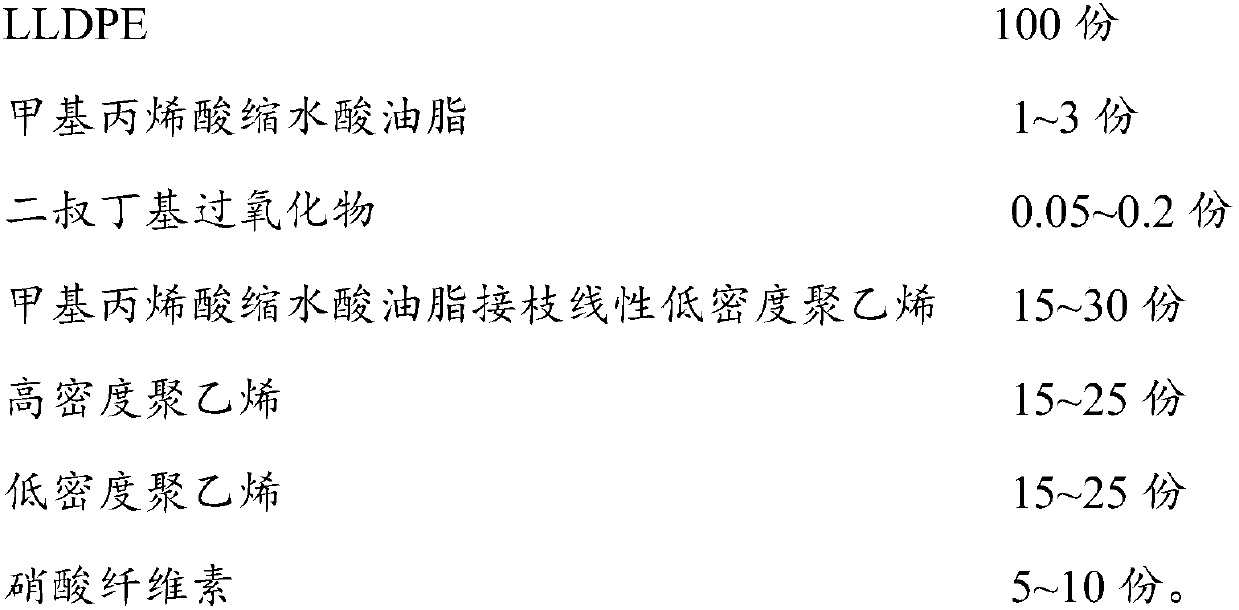

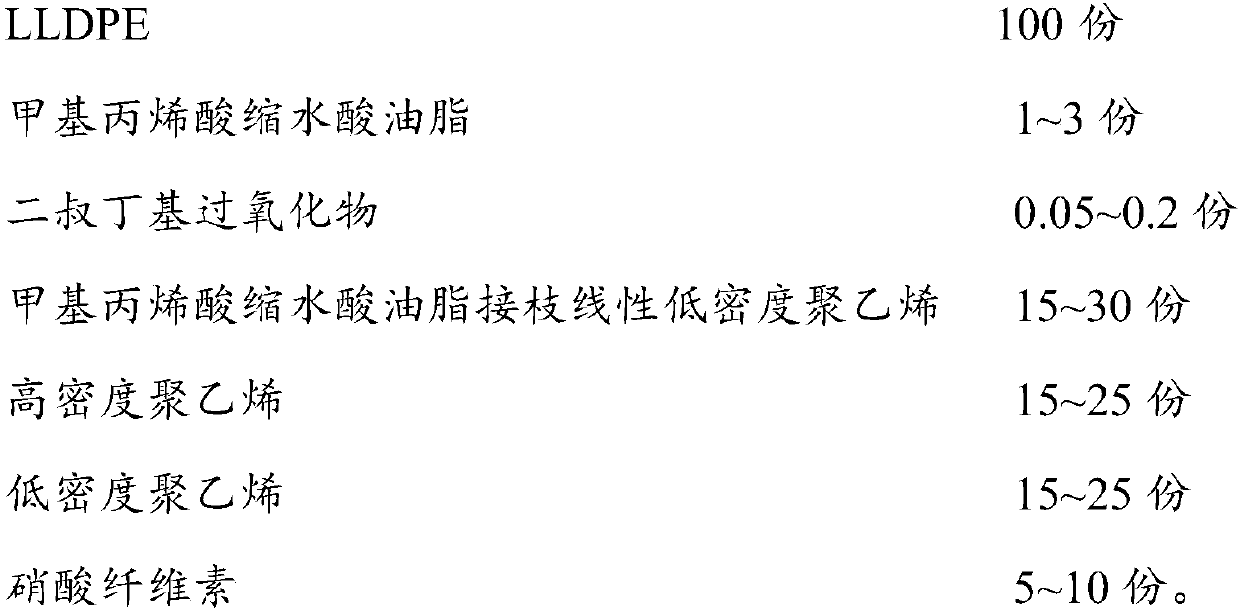

Embodiment 1

[0022]

[0023] Preparation of masterbatch: Mix LLDPE, methacrylic acid shrinkage grease, and initiator di-tert-butyl peroxide in a high-speed mixer, and then carry out melt grafting in a twin-screw extruder at a speed of 1000rpm. The temperature is divided into four zones, 190°C, 200°C, 210°C, and 220°C, and it is extruded, water-cooled, air-dried, and pelletized.

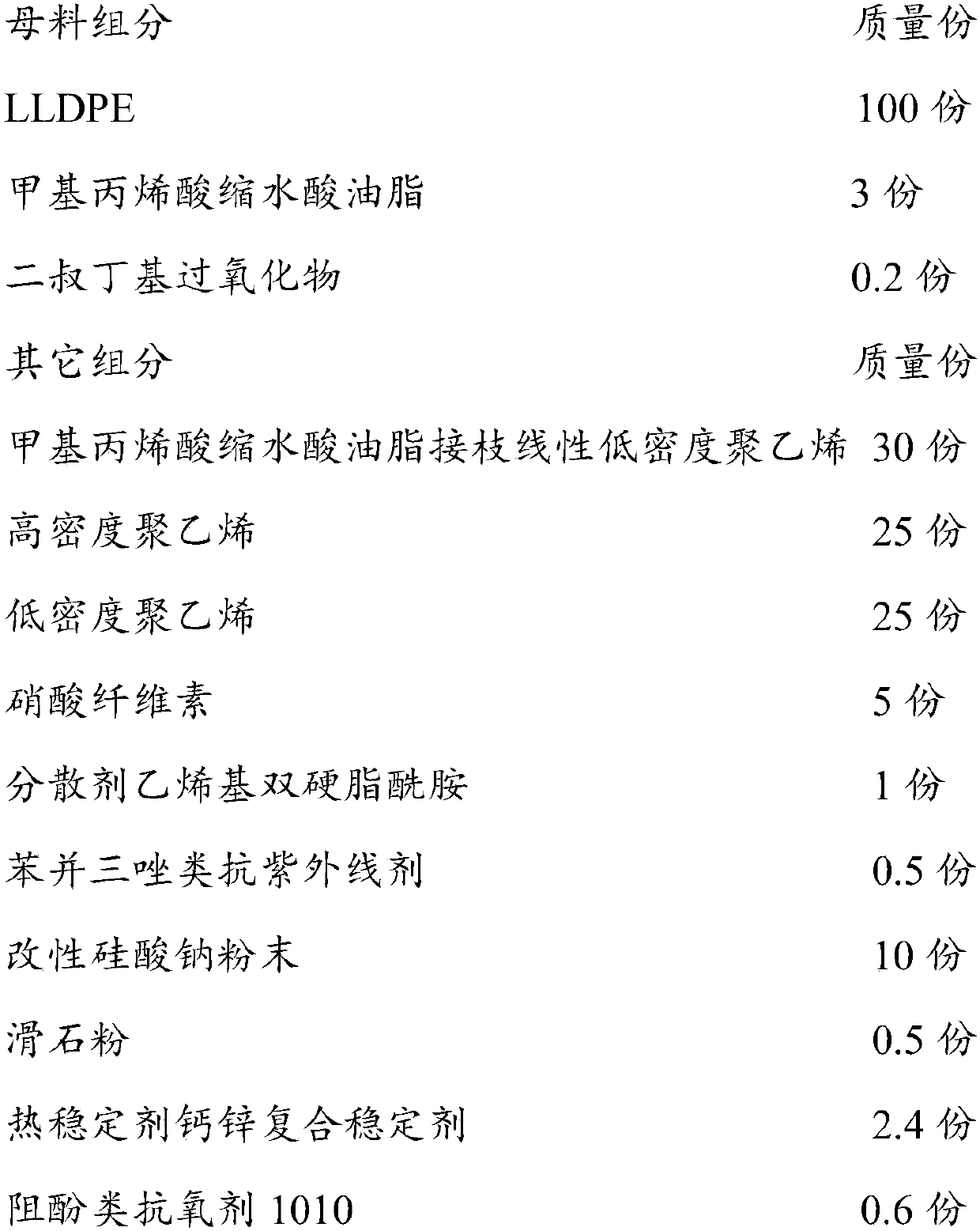

[0024] Adhesive resin preparation:

[0025] Graft masterbatch, high-density polyethylene, low-density polyethylene, nitrocellulose, dispersant vinyl bisstearamide, benzotriazole anti-ultraviolet agent, modified sodium silicate powder, talc powder, heat stabilizer Calcium-zinc composite stabilizer and hindered phenolic antioxidant are added according to the above ratio at an appropriate feeding position through multi-point and multi-channel methods, mixed at high speed until evenly mixed, and passed through a twin-screw extruder at 180-210°C. Extrude, granulate and dry to obtain the adhesive resin.

[0026] Th...

Embodiment 2

[0028]

[0029] Preparation of masterbatch: Mix LLDPE, methacrylic acid shrinkage grease, and initiator di-tert-butyl peroxide in a high-speed mixer, and then carry out melt grafting in a twin-screw extruder at a speed of 1000rpm. The temperature is divided into four zones, 190°C, 200°C, 210°C, and 220°C, and it is extruded, water-cooled, air-dried, and pelletized.

[0030] Adhesive resin preparation:

[0031] Graft masterbatch, high-density polyethylene, low-density polyethylene, nitrocellulose, dispersant vinyl bisstearamide, benzotriazole anti-ultraviolet agent, modified sodium silicate powder, talc powder, heat stabilizer Calcium-zinc composite stabilizer and hindered phenolic antioxidant are added according to the above ratio at an appropriate feeding position through multi-point and multi-channel methods, mixed at high speed until evenly mixed, and passed through a twin-screw extruder at 180-210°C. Extrude, granulate and dry to obtain the adhesive resin.

[0032] Th...

Embodiment 3

[0034]

[0035] Preparation of masterbatch: Mix LLDPE, methacrylic acid shrinkage grease, and initiator di-tert-butyl peroxide in a high-speed mixer, and then carry out melt grafting in a twin-screw extruder at a speed of 1000rpm. The temperature is divided into four zones, 190°C, 200°C, 210°C, and 220°C, and it is extruded, water-cooled, air-dried, and pelletized.

[0036] Adhesive resin preparation:

[0037] Graft masterbatch, high-density polyethylene, low-density polyethylene, nitrocellulose, dispersant vinyl bisstearamide, benzotriazole anti-ultraviolet agent, modified sodium silicate powder, talc powder, heat stabilizer Calcium-zinc composite stabilizer and hindered phenolic antioxidant are added according to the above ratio at an appropriate feeding position through multi-point and multi-channel methods, mixed at high speed until evenly mixed, and passed through a twin-screw extruder at 180-210°C. Extrude, granulate and dry to obtain the adhesive resin.

[0038] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com