Compressed sealing material for solid oxide fuel cell stack and preparation method of compressed sealing material

A solid oxide, fuel cell stack technology, used in fuel cells, fuel cell parts, sealing/supporting devices, etc. Low cost, stable and reliable quality, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~4

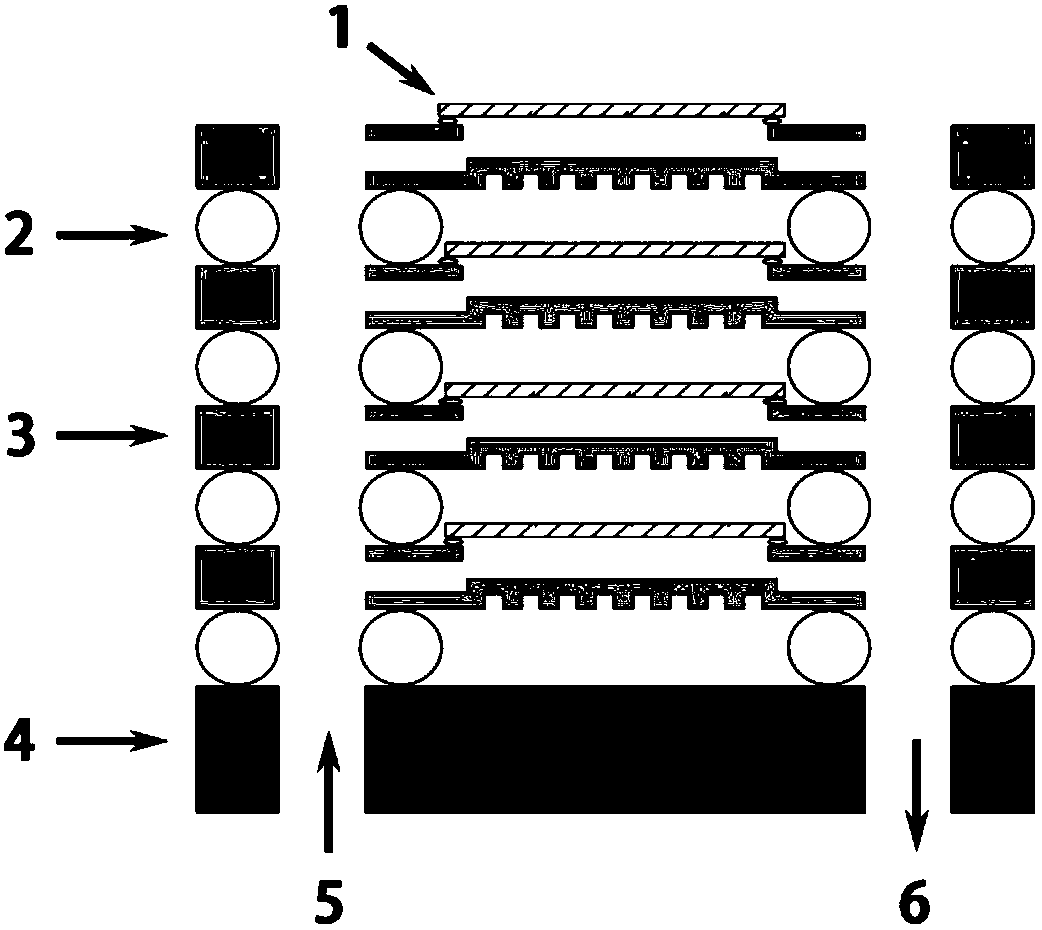

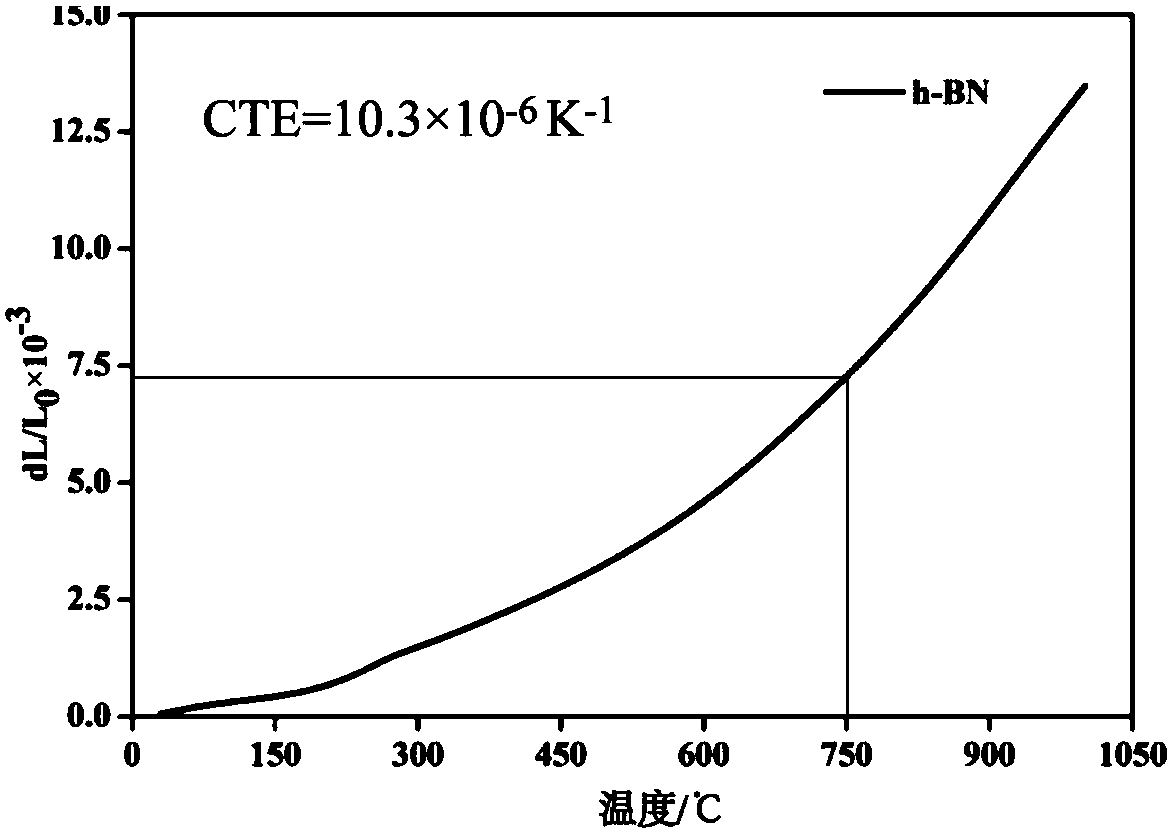

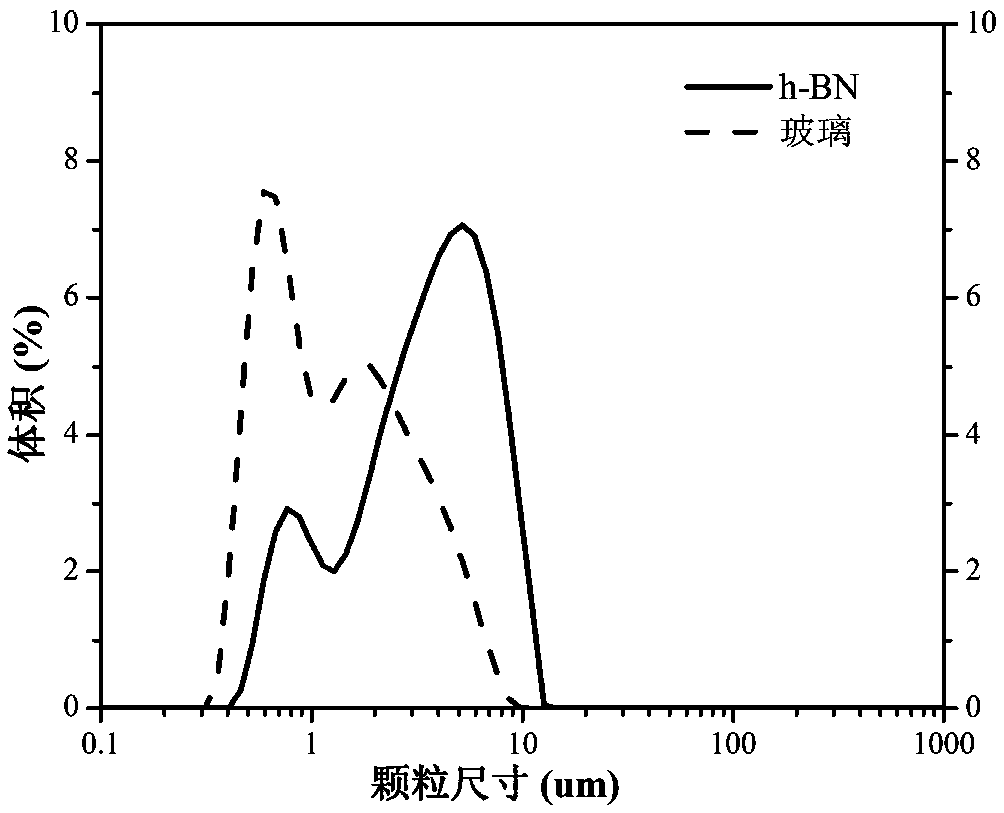

[0036] Preparation of Example 1~4h-BN-based sealing material

[0037] According to the ratio of raw materials in Table 1, the required raw materials were weighed according to the total amount of 100g. Add 300g zirconia balls into the ball mill tank as the ball milling medium, mix ethanol and xylene solution as the solvent, use herring oil as the dispersant, add the powder and ball mill for 12 hours, then use polyvinyl butyral (PVB) as the bond Agent, polyalkylene glycol and butyl benzyl ester as plasticizer, cyclohexanone as defoamer, added to the mixed slurry for ball milling for 12 hours, then added a certain amount of solvent to continue ball milling for 24 hours; in the process of ball milling, ZrO 2 The ball is the ball milling medium, and the ratio of the ball milling beads to the added powder is about 3:1. After ball milling to become a homogeneous slurry, vacuum degassing is used to form a plain embryo with controllable thickness and smooth surface by using a precision...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com