Synthesis technology of tetrahydroxy diboron

A technique for the synthesis of tetrahydroxydiboron, which is applied in the direction of boron oxide compounds, boron oxyacids, etc., can solve problems such as large fluctuations in yield, and achieve the effects of safe and controllable process, obvious yield, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

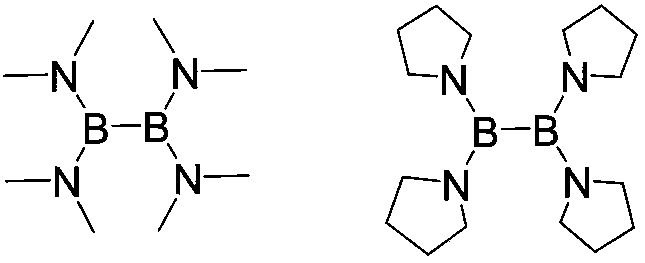

Embodiment 1

[0020] In the reaction flask, after adding 10% hydrochloric acid (4.5eq), the temperature was lowered to 0°C, and tetrakis(dimethylamino)biboron (39.6g, 0.2mol, 1.0eq) was slowly added dropwise to the above hydrochloric acid solution, and added dropwise. During the process, there is gradually a solid precipitation, and the dropwise addition is completed, gradually rising to room temperature and stirring for 3 hours, filtering to obtain 16.9 g of a white solid product after vacuum drying at 40-60 ° C, a yield of 94.2%; GC derivatization (dissolving the product in In methanol, add pinacol derivatization) detection content 97.9%, HPLC: 99.5%; HNMR (DMSO-d6+H2O): 8.84 (0.02), 8.61 (1.00), 7.59 (5.28), 6.50 (0.02) {Note: The peak area value in brackets}; the above product was added with 60 mL of 0.05% dilute hydrochloric acid, stirred for 30 minutes under temperature control at 5-10 °C, filtered, and the obtained solid was dried at 40-60 °C to obtain 16.5 g of white product. Conten...

Embodiment 2

[0022] In the reaction flask, after adding 10% hydrochloric acid (5.5eq), the temperature was lowered to 10°C, and tetrakis(dimethylamino)biboron (39.6g, 0.2mol, 1.0eq) was slowly added dropwise to the above hydrochloric acid solution, and added dropwise. During the process, the temperature was controlled within 30°C, and a solid was gradually precipitated, and the dropwise addition was completed, stirring at room temperature for 3 hours, and filtering to obtain 16.2g of a white solid product after vacuum drying at 40-60°C, with a yield of 90.4%; GC derivatization ( Dissolve the product in methanol, add pinacol derivatization) detection content 97.3%, HPLC: 99.6%; HNMR (DMSO-d6+H2O): 8.84, 8.61, 7.59.

Embodiment 3

[0024] In the reaction flask, after adding 10% nitric acid (4.8eq), the temperature was lowered to -10°C, and tetrakis(dimethylamino)biboron (39.6g, 0.2mol, 1.0eq) was slowly added dropwise to the above nitric acid solution, dropwise During the adding process, gradually there is solid precipitation, the temperature is controlled within 0 ℃, the dropwise addition is completed, gradually rise to room temperature and keep stirring for 3 hours, filter to obtain 16.7g of white solid product after vacuum drying at 40-60 ℃, the yield is 93.3% ; GC derivatization (dissolve the product in methanol, add pinacol derivatization) detection content 97.3%, HPLC: 99.6%; HNMR (DMSO-d6+H2O): 8.84, 8.61, 7.59.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com