A kind of lignite bio-fertilizer and production method thereof

A bio-fertilizer and bio-organic fertilizer technology, which is applied in the fields of fertilization methods, botany equipment and methods, and bio-organic part treatment, can solve problems such as production research that has not been reported, and achieve obvious yield, obvious effect, and bright green leaves Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: the preparation of lignite bio-organic fertilizer

[0026] %According to the weight percentage, using lignite as the raw material and corn stalks and cotton stalks as auxiliary materials, the lignite is crushed to less than 50 mesh, the length of the auxiliary materials is crushed to less than 2mm, and the auxiliary materials are added to the coal powder to form the ingredients. The ratio is lignite 40%-50%, 20%-25% corn straw, 10%-15% cotton straw, adjust the moisture to 30-50%, and then put Davidiella Tassiana CGMCC No.7440 and Streptomyces griseus ( Streptomyces griseoplanus) CGMCC No.8194 fermented liquid was put into the above ingredients by 10% by v / w, stirred evenly, and the pH of the ingredients was adjusted to 6.5 to 7.5. After 5-7 days of incubation and fermentation at 28°C, it was dried and pulverized to obtain lignite bio organic fertilizer.

[0027] The lignite bio-organic fertilizer obtained by the above preparation method, % is calcula...

Embodiment 2

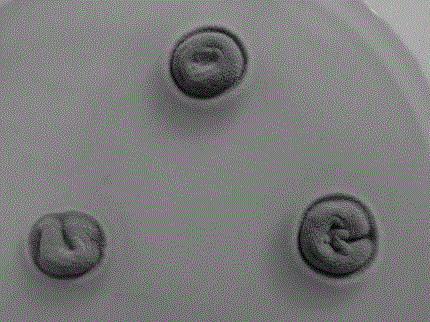

[0030] Embodiment two: Davidiella Tassiana Isolation, screening, classification and identification of CGMCC No. 7440

[0031] (1) Isolation and screening of strains

[0032] Through the separation, screening and cultivation of coal samples in the coal mine area of Fukang City, Xinjiang, a batch of microbial strains that can degrade low-rank coal in Xinjiang were obtained. After further screening, the specific steps of screening are: take 1g of mine coal samples, Add sterile water and dilute to 10 0 、10 -1 and 10 -2 Three gradient concentrations were evenly spread on the CDA solid medium, and cultured at 25°C. After the colonies had fully grown, colonies of different shapes were selected and reinoculated into the CDA solid medium for purification. Repeated purification for 5 generations, after After plate screening, 7 lignite-degrading strains were isolated; after further re-screening, the degradation strain RM-1 was obtained. A strain numbered RM-1 was screened out, an...

Embodiment 3

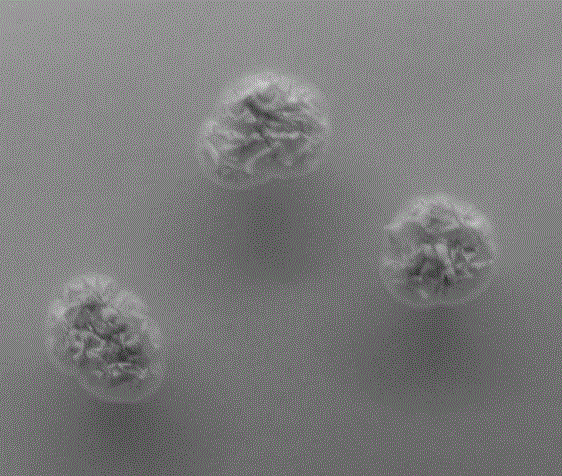

[0042] Embodiment three: streptomyces griseus ( Streptomyces griseoplanus ) Isolation, screening, classification and identification of CGMCC No.8194

[0043] (1) Isolation and screening of strains: through the separation, screening and cultivation of coal samples in the Shawan coal mine area of Xinjiang, a batch of microbial strains that can degrade low-rank coal in Xinjiang were obtained, and the specific steps of screening were further screened Yes: Take 1g of mine coal sample, add sterile water, dilute to three gradient concentrations of 100, 10-1 and 10-2, spread evenly on NA solid medium, 28 ℃, static culture, until the colony After sufficient growth, colonies of different shapes were selected and re-inoculated into NA solid medium for purification. In this way, the purification was repeated for 5 generations. After plate screening, a total of 7 lignite-degrading strains were isolated; after further re-screening, the degradation strain RM-201 was obtained. A strain nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com