A glass fiber production wastewater treatment equipment and treatment method

A technology for producing wastewater and glass fiber, which is applied in biological water/sewage treatment, natural water treatment, multi-stage water treatment, etc. It can solve the problems of fine particles, small area load capacity of sedimentation tank, light specific gravity of organic polymer particles, etc. Achieve the effect of ensuring the treatment effect, reducing the difficulty of operation and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

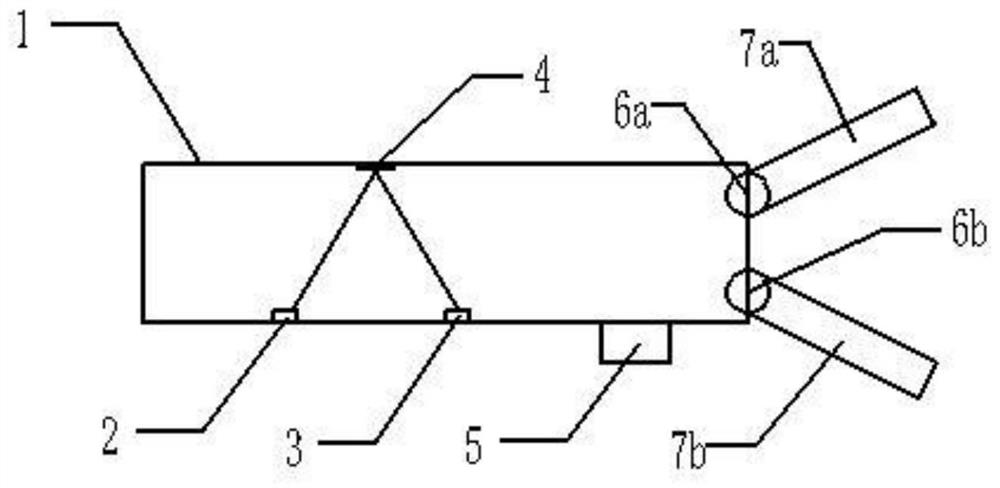

[0019] The specific structure of a glass fiber production wastewater treatment equipment and a glass fiber production wastewater treatment method of the present invention will be described in detail below in conjunction with the accompanying drawings.

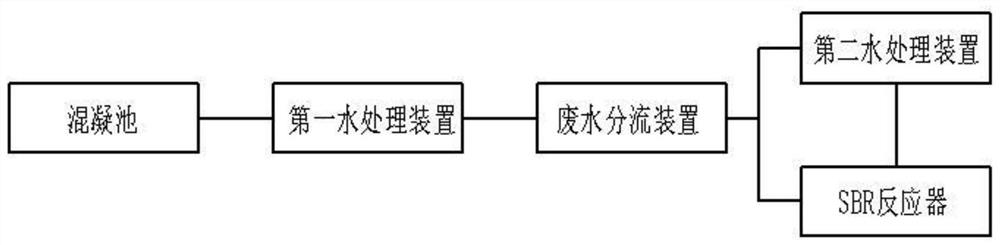

[0020] Such as figure 1 and figure 2 As shown, a glass fiber production wastewater treatment equipment of the present invention includes a coagulation tank, a first water treatment device, a wastewater diversion device, a second water treatment device and an SBR reactor. The coagulation tank includes a water inlet and a water outlet. There is a grille at the water inlet of the coagulation tank, which can perform preliminary screening of the glass fiber production wastewater to filter out some impurities. The water outlet of the coagulation tank is connected to the first water treatment device. , after the wastewater is treated in the coagulation tank, it enters the first water treatment device through the water outlet for tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com