Preparation and application of CVD graphene composite glass

A graphene composite and graphene technology, applied in the direction of coating, etc., can solve problems such as threats to the lives of members of the car and pedestrians, hidden safety hazards in high-rise building cleaning, and complicated transfer process of graphene, so as to achieve easy industrialization and mature technical routes , The effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

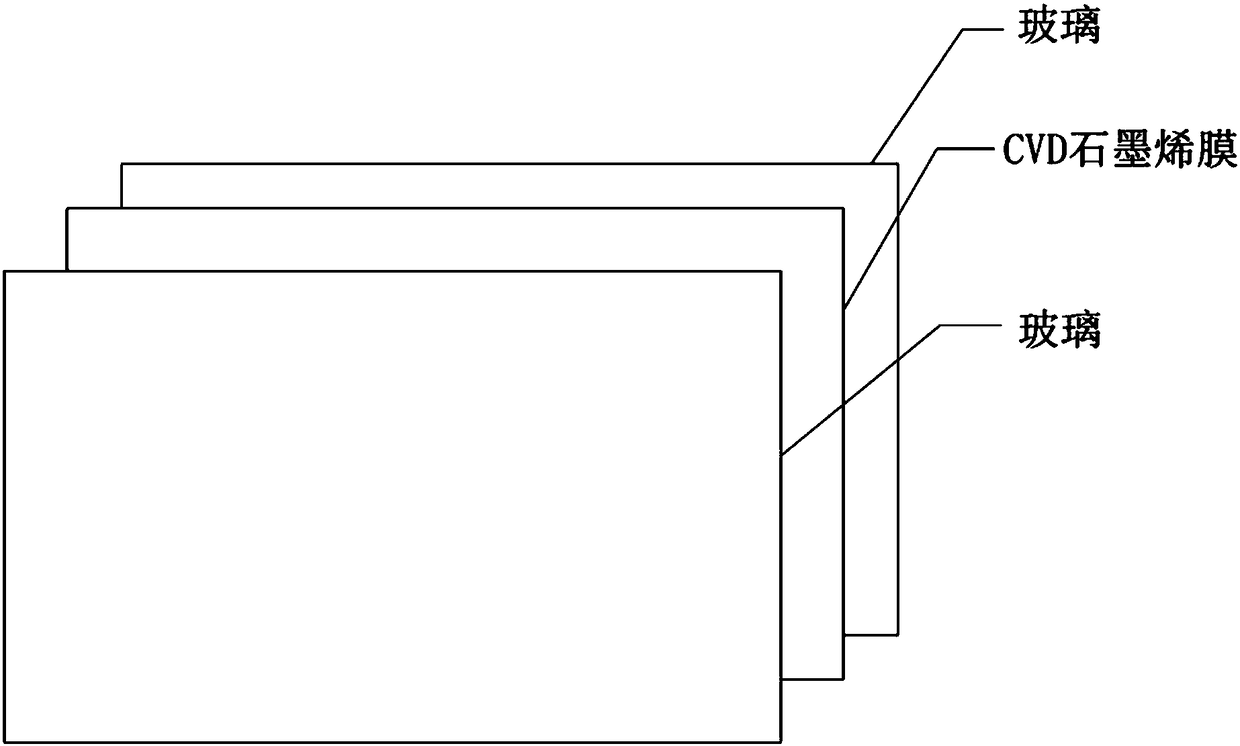

[0018] (1) Graphene CVD film preparation: the gaseous carbon source, inert gas, and oxygen are passed into the reaction chamber, and the pressure, temperature, and atmosphere concentration are controlled. The gaseous carbon source, inert gas, and oxygen atmosphere concentration volume ratio are 1:1:0.1 , the gaseous carbon source is methane CH 4 , control the temperature at a high temperature of 900°C, and control the pressure at 0.5Mpa, burst the gaseous carbon source to separate C and H, and then quickly apply positive and negative electric fields in the reaction chamber to speed up the separation of C and H, and make carbon rapidly resist high temperature A layer of graphene is deposited and grown on the surface of the glass, the electric field is removed, and the glass deposited with a layer of graphene is automatically separated from the reaction chamber.

[0019] (2) Preparation of heat-generating glass: Cover another piece of glass on the glass on one side of the graphe...

Embodiment 2

[0021] (1) Preparation of graphene CVD film: the gaseous carbon source, inert gas, and oxygen are passed into the reaction chamber, and the pressure, temperature, and atmosphere concentration are controlled. The gaseous carbon source is acetylene C 2 h 2 , the gaseous carbon source, inert gas, and oxygen atmosphere concentration volume ratio are 1:5:0.5, the temperature is controlled at a low temperature of 450°C, and the pressure is controlled at 2.5Mpa. The gaseous carbon source is burst to separate C and H, and then rapidly in the reaction chamber Apply positive and negative electric fields to speed up the separation of C and H, and at the same time, make carbon quickly deposit and grow a layer of graphene on the surface of the temperature-resistant glass, remove the electric field, and automatically separate the glass deposited with a layer of graphene out of the reaction chamber.

[0022] (2) Preparation of heat-generating glass: Cover another piece of glass on the glass ...

Embodiment 3

[0024] (1) Preparation of graphene CVD film: the gaseous carbon source, inert gas, and oxygen are passed into the reaction chamber, and the pressure, temperature, and atmosphere concentration are controlled. The gaseous carbon source is methane CH 4 , Vinyl C 2 h 4 , CH 4 、C 2 h 4 , The gaseous carbon source, inert gas, and oxygen atmosphere concentration volume ratio are 0.7:0.3:2:0.3, the control temperature is medium temperature 650°C, and the control pressure is 1Mpa. The gaseous carbon source is burst to separate C and H, and then in the reaction chamber Rapidly apply positive and negative electric fields in the middle to accelerate the separation of C and H, and at the same time, make carbon quickly deposit and grow a layer of graphene on the surface of the medium temperature resistant glass, remove the electric field, and automatically separate the glass deposited with a layer of graphene out of the reaction chamber.

[0025] (2) Glass augmented reality technology: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com