Preparation method of graphene and method for static conductive graphene EPS

A graphene and static-conducting technology, applied in coatings and other directions, can solve problems such as low mechanical strength of EPS and restrict EPS, and achieve the effect of reducing production costs, reducing costs and environmental protection costs, and broadening the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Oxidative intercalation of graphite: use graphite with a particle size of 800 mesh as raw material, with a purity of 99%, mix graphite with an oxidizing intercalation agent for intercalation, and the oxidizing intercalation agent system is 90% concentrated sulfuric acid, sodium nitrate, high Potassium manganate system, the mass ratio is graphite:concentrated sulfuric acid:sodium nitrate:potassium permanganate=1:1:0.1:0.5;

[0047] (2) Preparation of graphene by continuous expansion of high-frequency microwave: 915MHz high-frequency microwave is used to continuously expand intercalated graphite for 20 seconds, and the output power is controlled to 300KW. ene, specific surface area 2000m 2 / g, the thickness of the sheet is 0.33-1nm;

[0048] (3) Alcohol washing modification of graphene: mix graphene with a certain amount of ethylene glycol for 1h, the mass ratio of graphene and ethylene glycol is 1:5, filter and dry after alcohol washing modification;

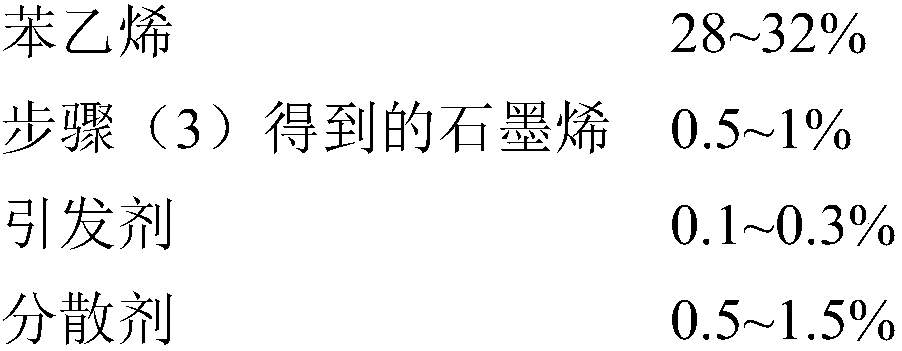

[0049] (4) T...

Embodiment 2

[0053] (1) Oxidative intercalation of graphite: use graphite with a particle size of 1100 mesh as raw material, with a purity of 99.9%, mix graphite with an oxidative intercalation agent for intercalation, and the oxidative intercalation agent system is 95% concentrated sulfuric acid, potassium nitrate, high Potassium manganate system, the mass ratio is graphite:concentrated sulfuric acid:potassium nitrate:potassium permanganate=1:5:0.5:1;

[0054] (2) Preparation of graphene by high-frequency microwave continuous expansion: 915MHz high-frequency microwave continuously expands the intercalated graphite for 200S, controls and controls the output power to 200KW, and performs simple ultrasonic exfoliation after discharging to form single-layer graphite with 1-2 layers ene, specific surface area 2500m 2 / g, the thickness of the sheet is 0.33-1nm;

[0055] (3) Alcohol washing modification of graphene: mix graphene with a certain amount of polyethylene glycol 1000 (molecular weight...

Embodiment 3

[0061] (1) Oxidative intercalation of graphite: use graphite with a particle size of 1200 mesh as raw material, with a purity of 99.5%, mix graphite with an oxidative intercalation agent for intercalation, and the oxidative intercalation agent system is 98% concentrated sulfuric acid, sodium nitrate, nitric acid Potassium, potassium permanganate system, the mass ratio is graphite:concentrated sulfuric acid:sodium nitrate:potassium nitrate:potassium permanganate=1:3:0.1:0.2:0.7;

[0062] (2) Preparation of graphene by high-frequency microwave continuous expansion: 915MHz high-frequency microwave continuously expands the intercalated graphite for 130S, controls and controls the output power to 250KW, and performs simple ultrasonic exfoliation after discharging into single-layer graphite with 1-2 layers ene, specific surface area 2200m 2 / g, the thickness of the sheet is 0.33-1nm;

[0063] (3) Alcohol washing modification of graphene: mix graphene with a certain amount of ethyle...

PUM

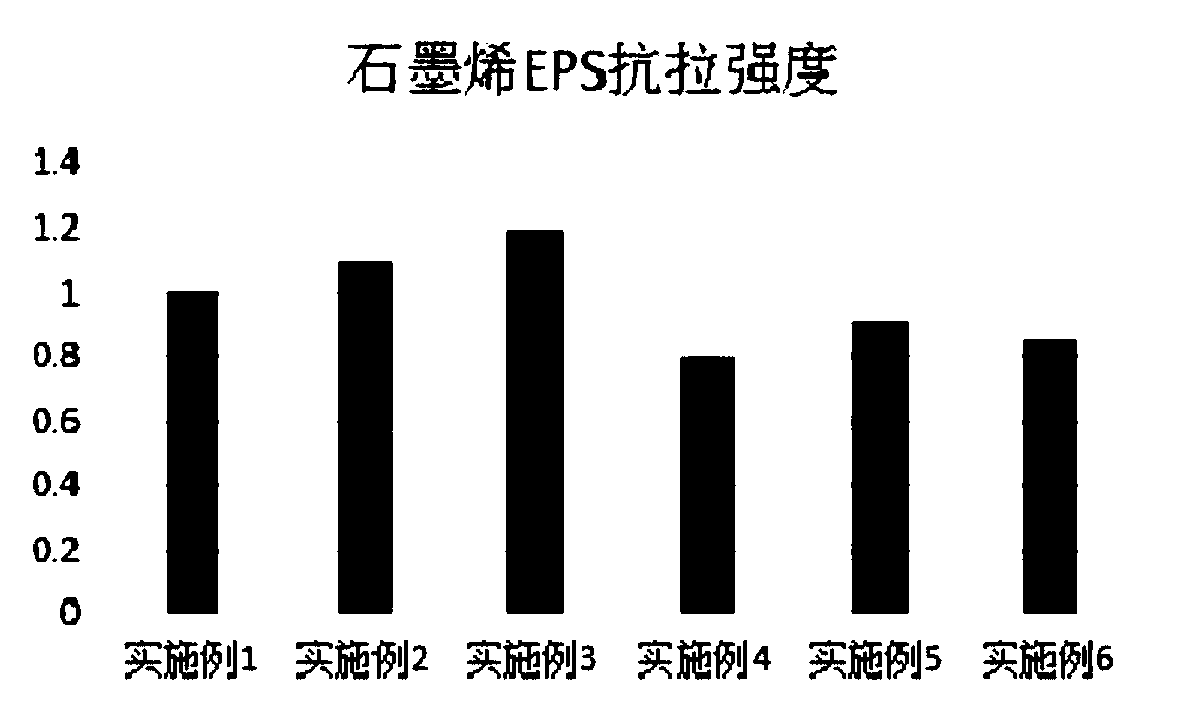

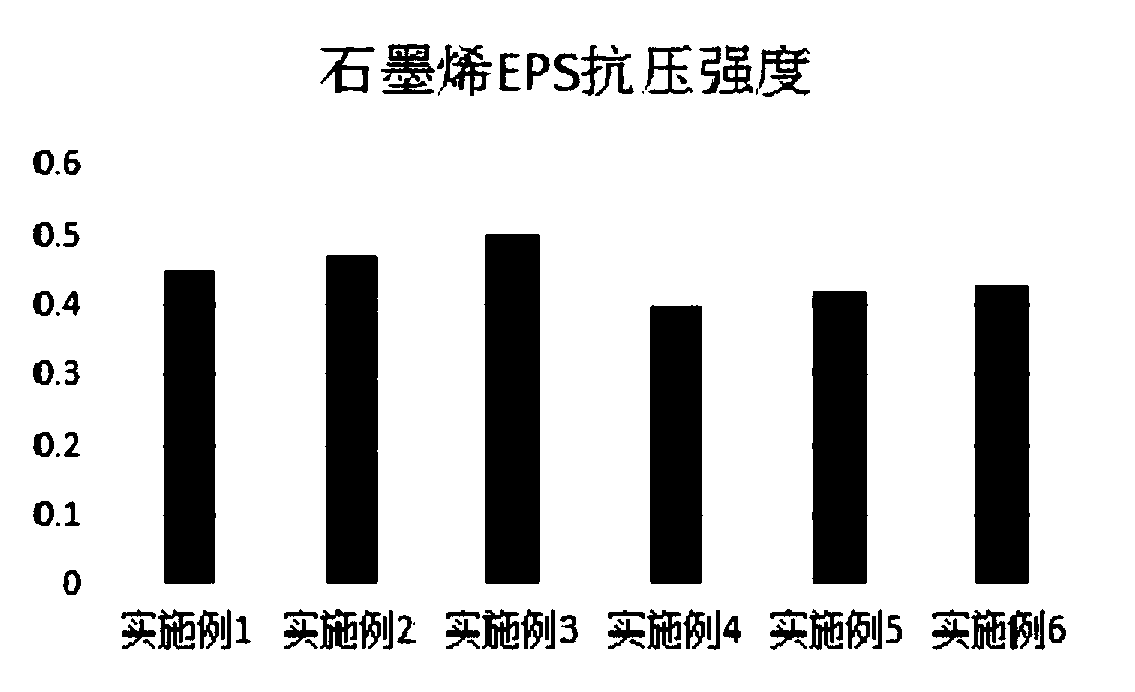

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com