A kind of preparation method of graphene 3D printing alloy material

A 3D printing and alloy material technology, applied in the field of graphene 3D printing alloy material preparation, can solve the problems of limited 3D printing materials, and achieve the effect of less internal stress defects, improved active area and reaction performance, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

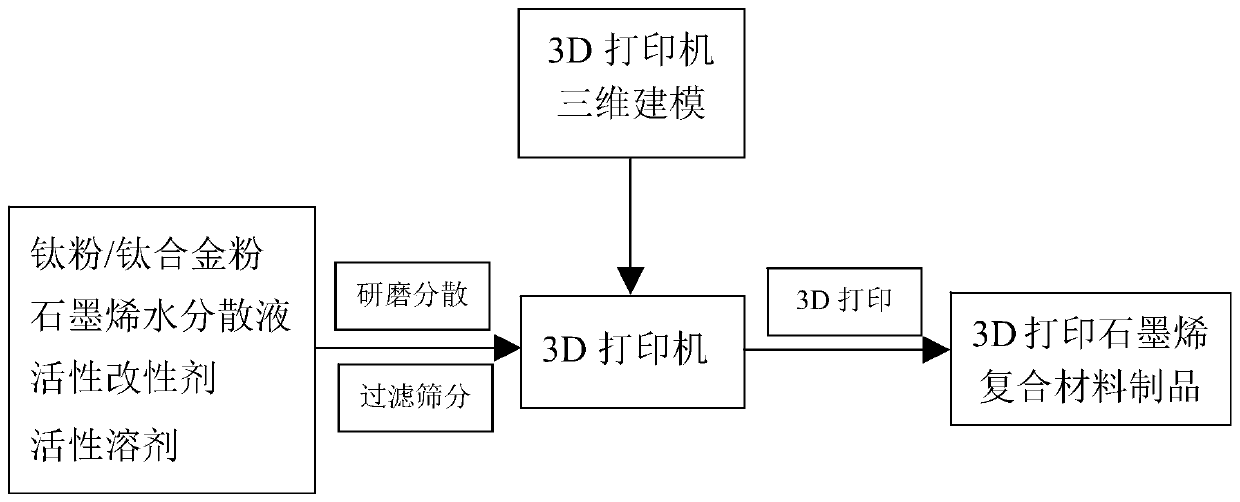

Method used

Image

Examples

Embodiment 1

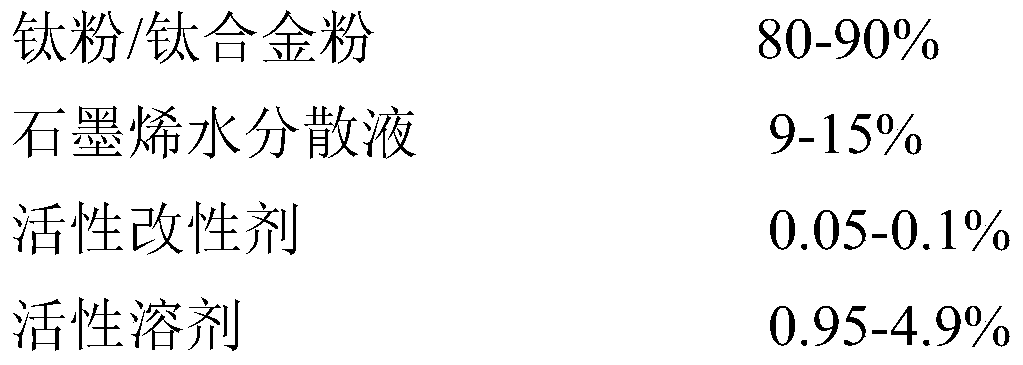

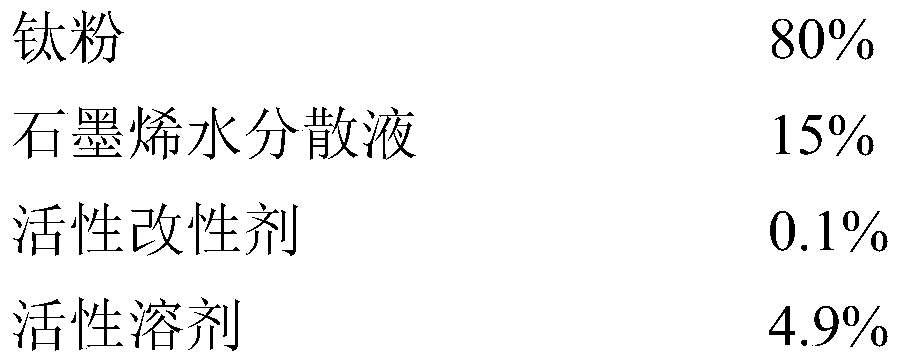

[0021] (1) Preparation of graphene-titanium alloy powder: titanium powder (average particle size 1um) for 3D printing, graphene aqueous dispersion (graphene mass fraction is 5%), active modifier polyethylene glycol 400 (molecular weight 400, the same below), the active solvent DBE is mixed, ground and dispersed, filtered and sieved to obtain a graphene-titanium composite 3D printing material, and the mass ratio is as follows;

[0022]

[0023] (2) Three-dimensional modeling of 3D printer: use computer to draw the three-dimensional graphics of the parts to be printed, and input them into the 3D printer;

[0024] (3) 3D printing graphene-titanium composite material: Add the prepared graphene-titanium composite powder into the 3D printer, and then 3D print it into various required parts and materials. The atmosphere needs to be protected by inert gas during printing .

[0025] Wherein, the particle size of the titanium powder is 5-10um; the number of graphene layers in the gr...

Embodiment 2

[0027] (1) Preparation of graphene-titanium alloy powder: titanium alloy powder for 3D printing (average particle size 30um), graphene aqueous dispersion (graphene mass fraction is 15%), active modifier polyethylene glycol 10000, 0.5% active solvent ethanol and 0.45% terpineol were mixed, ground and dispersed, filtered and sieved to obtain a graphene-titanium composite 3D printing material, and the mass ratio was as follows;

[0028]

[0029]

[0030] (2) Three-dimensional modeling of 3D printer: use computer to draw the three-dimensional graphics of the parts to be printed, and input them into the 3D printer;

[0031] (3) 3D printing graphene-titanium composite material: Add the prepared graphene-titanium composite powder into the 3D printer, and then 3D print it into various required parts and materials. The atmosphere needs to be protected by inert gas during printing .

[0032] Wherein, the particle size of the titanium alloy powder is 10-15um; the number of graphen...

Embodiment 3

[0034] (1) Preparation of graphene-titanium alloy powder: titanium powder for 3D printing (average particle size 10um), graphene aqueous dispersion (graphene mass fraction is 8%), active modifier polyethylene glycol 3000, active The solvent ethylene glycol butyl ether acetate 1%, diethylene glycol butyl ether 1.3% are mixed and ground to disperse, filtered and sieved to obtain a graphene-titanium composite 3D printing material, and the mass ratio is as follows;

[0035]

[0036] (2) Three-dimensional modeling of 3D printer: use computer to draw the three-dimensional graphics of the parts to be printed, and input them into the 3D printer;

[0037] (3) 3D printing graphene-titanium composite material: Add the prepared graphene-titanium composite powder into the 3D printer, and then 3D print it into various required parts and materials. The atmosphere needs to be protected by inert gas during printing .

[0038] Wherein, the titanium powder particle size is 25-30um; the numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com