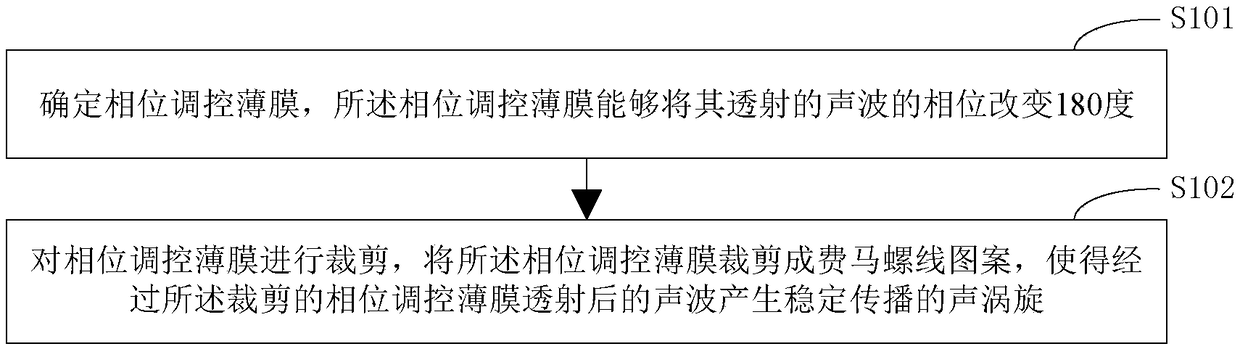

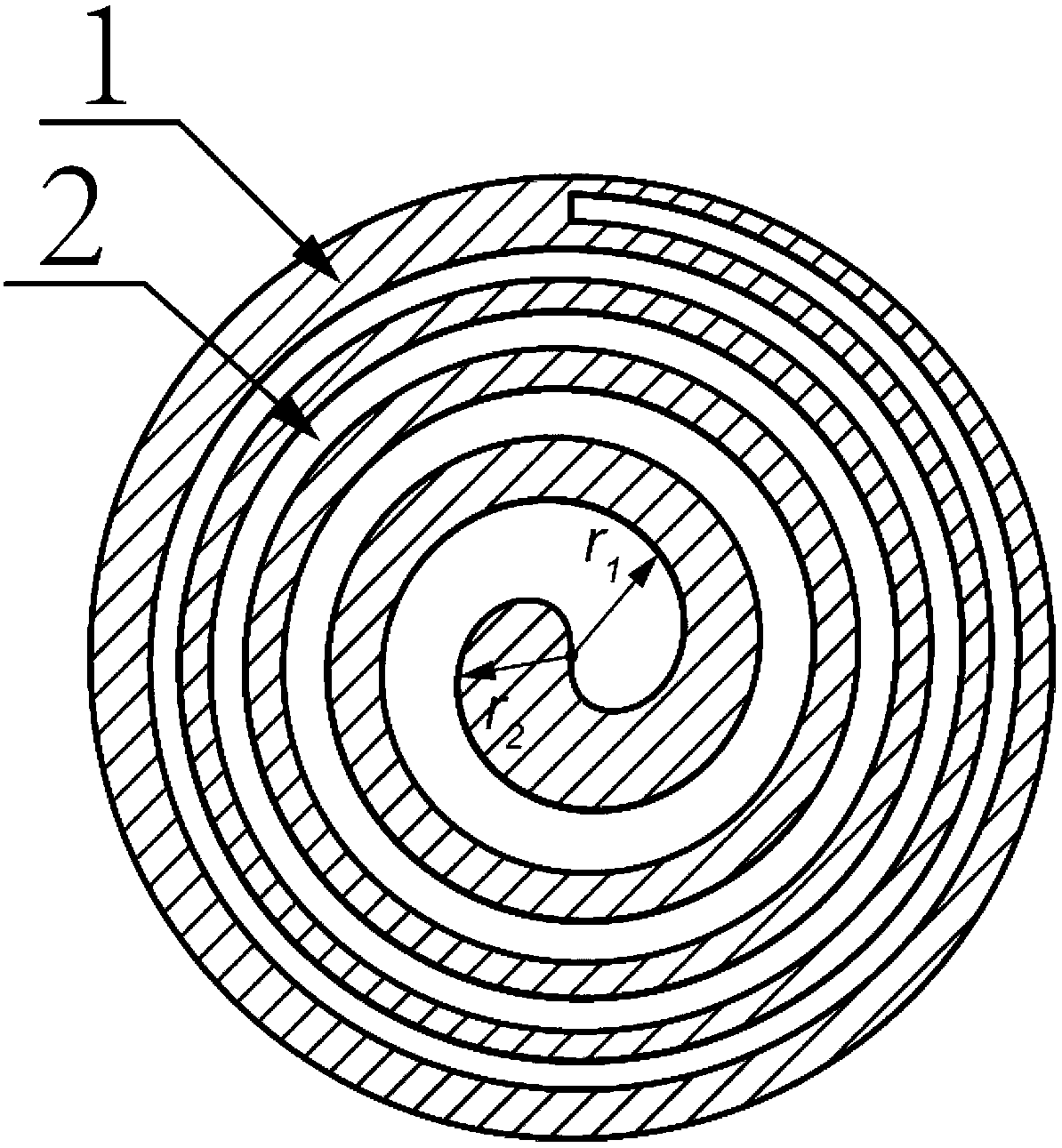

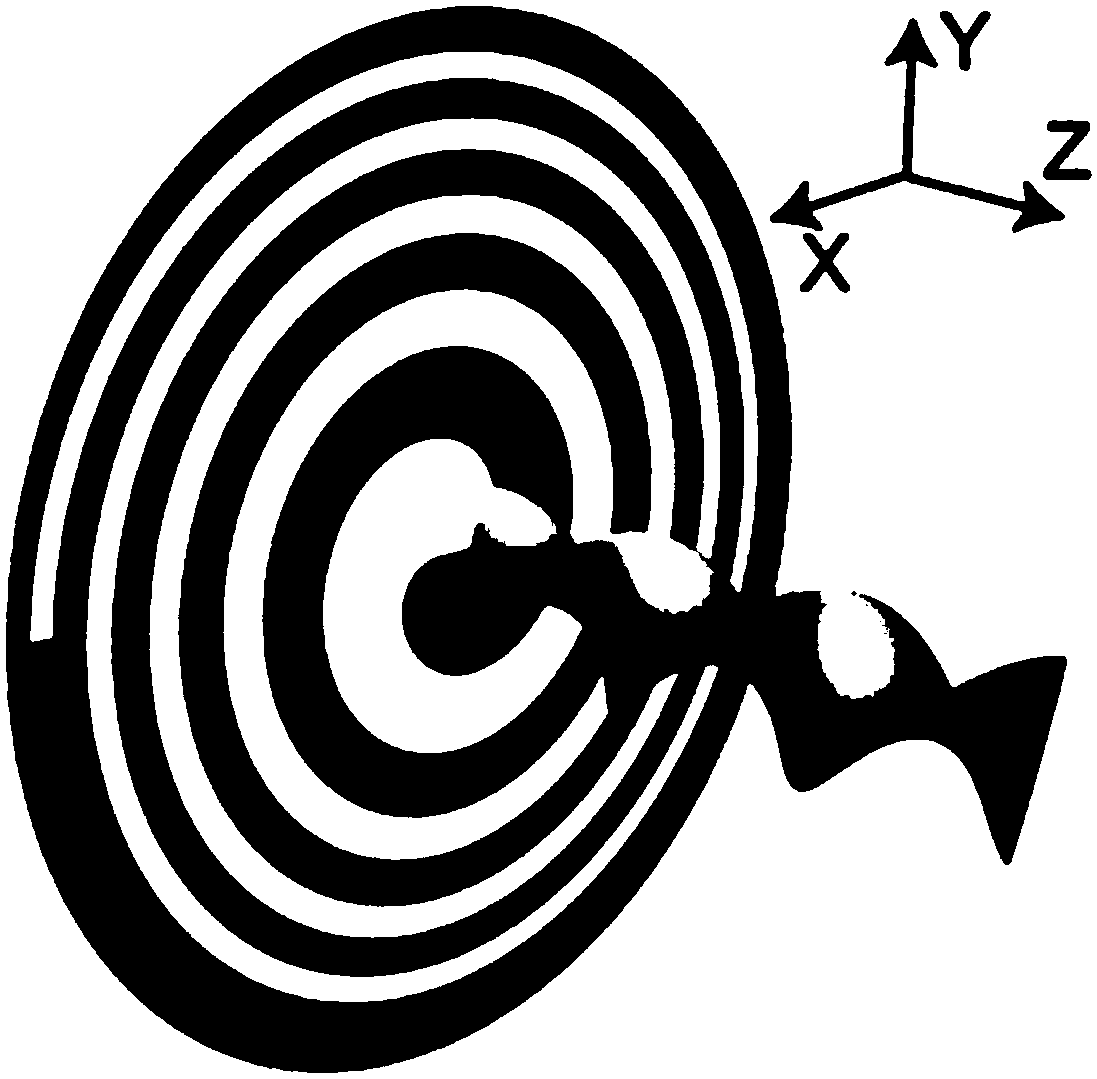

Method of forming sound vortex based on patterned tailoring technology

A patterned and vortex technology, applied in the field of acoustic waves, can solve the problems of large acoustic vortex devices, limited application range, and limited precision, and achieve the effects of size reduction, broad application prospects, and high energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Evenly mix copper particles with a diameter of 0.5 microns to 1.5 microns and polyvinyl alcohol (model: PVA124) aqueous solution. Need specific adjustments.

[0072] Wherein, the concentration of the polyvinyl alcohol solution in the embodiment of the present invention may also be other concentration with relatively stable dissolution.

[0073] In the embodiment of the present invention, copper particles: polyvinyl alcohol are given in four situations of 1:1, 1:2, 1:4, and 1:8. Using the mixed solution as a raw material, electrostatic spinning fibers with particles with a diameter of 0.5 micron to 1.5 micron can be obtained, and the electrostatic spinning film is formed by stacking the electrospinning fibers.

[0074] According to the mixed liquids with different mass ratios of copper particles and polyvinyl alcohol configured according to the present invention, after obtaining a uniformly mixed copper particle / polyvinyl alcohol mixed liquid, this can be used as a raw ...

Embodiment 2

[0076] Evenly mix lead oxide particles with a diameter of 0.5 microns to 1.5 microns and polyacrylonitrile (PAN) in dimethylformamide (DMF) solution (PAN is insoluble in water, soluble in organic solvents such as DMF, etc.), and the polyacrylonitrile used The concentration of the DMF solution is 8% to 12%, and the mass ratio of lead oxide particles and polyacrylonitrile is specifically adjusted according to actual needs.

[0077] Wherein, the concentration of the polyacrylonitrile solution in the embodiment of the present invention may also be other concentration with relatively stable dissolution.

[0078] In the embodiment of the present invention, lead oxide particles: polyacrylonitrile are given in four situations of 1:1, 1:4, 1:8, and 1:16. Using the mixed solution as a raw material, electrostatic spinning fibers with particles with a diameter of 0.5 micron to 1.5 micron can be obtained, and the electrostatic spinning film is formed by stacking the electrospinning fibers....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com