Method of manufacturing closed porous piezoelectret energy harvester based on nanoimprint

A piezoelectric electret, electric electret technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problem of affecting output stability, affecting elastic modulus, and voiding Problems such as forming a closed chamber to achieve the effect of improving energy capture efficiency, improving stability and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

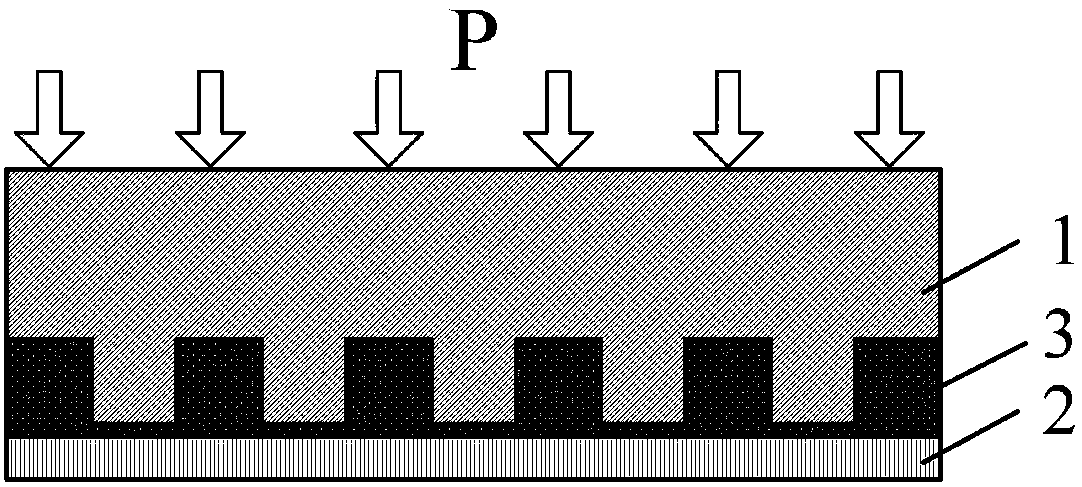

[0028] A method for preparing a closed porous piezoelectric electret energy harvester based on nanoimprinting, comprising the following steps:

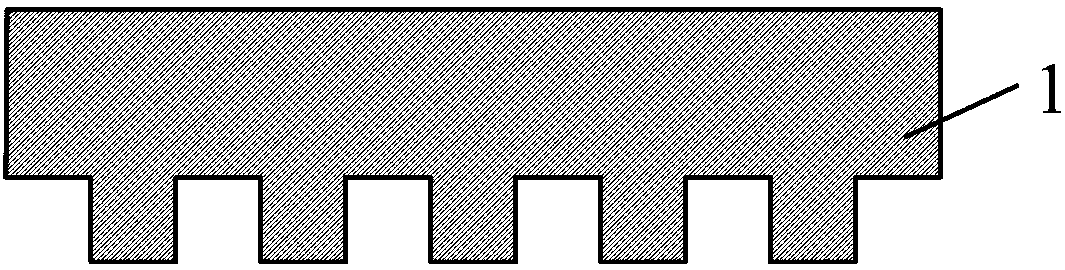

[0029] The first step, the preparation and processing of the imprinting mold: the imprinting mold 1 adopts photolithography and etching process to make a microhole array on the silicon wafer, such as figure 1 As shown, soak in fluorosilane solution for 6 hours after completion, and bake at 170°C for 12 hours for low surface energy treatment to prevent damage to the microarray structure during demoulding;

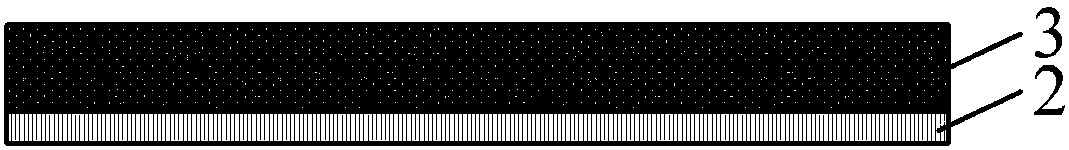

[0030] The second step is the preparation of piezoelectric electret film: the substrate 2 is made of flexible polyimide film (PI film), and a layer of piezoelectric electret with a thickness of micron level is spin-coated on the surface of the substrate 2 by using a coating machine. solution and evaporate the residual sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com