Prism type light beam scanning device and system for laser micro hole machining and light beam scanning method

A beam scanning and micro-hole processing technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of rubbing the edge of the center beam first, so as to improve the deep hole processing ability and solve the effect of rubbing the edge first.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

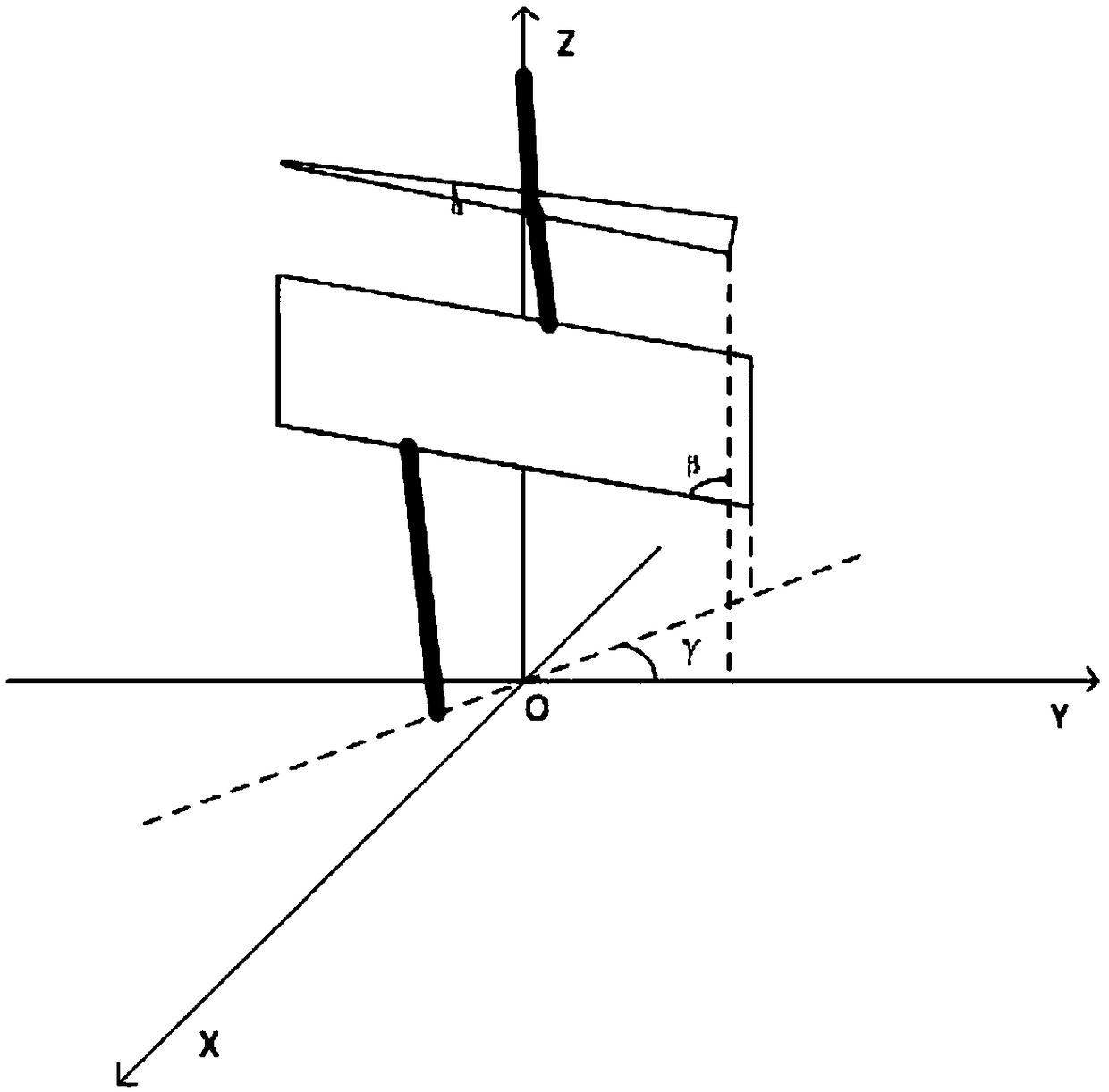

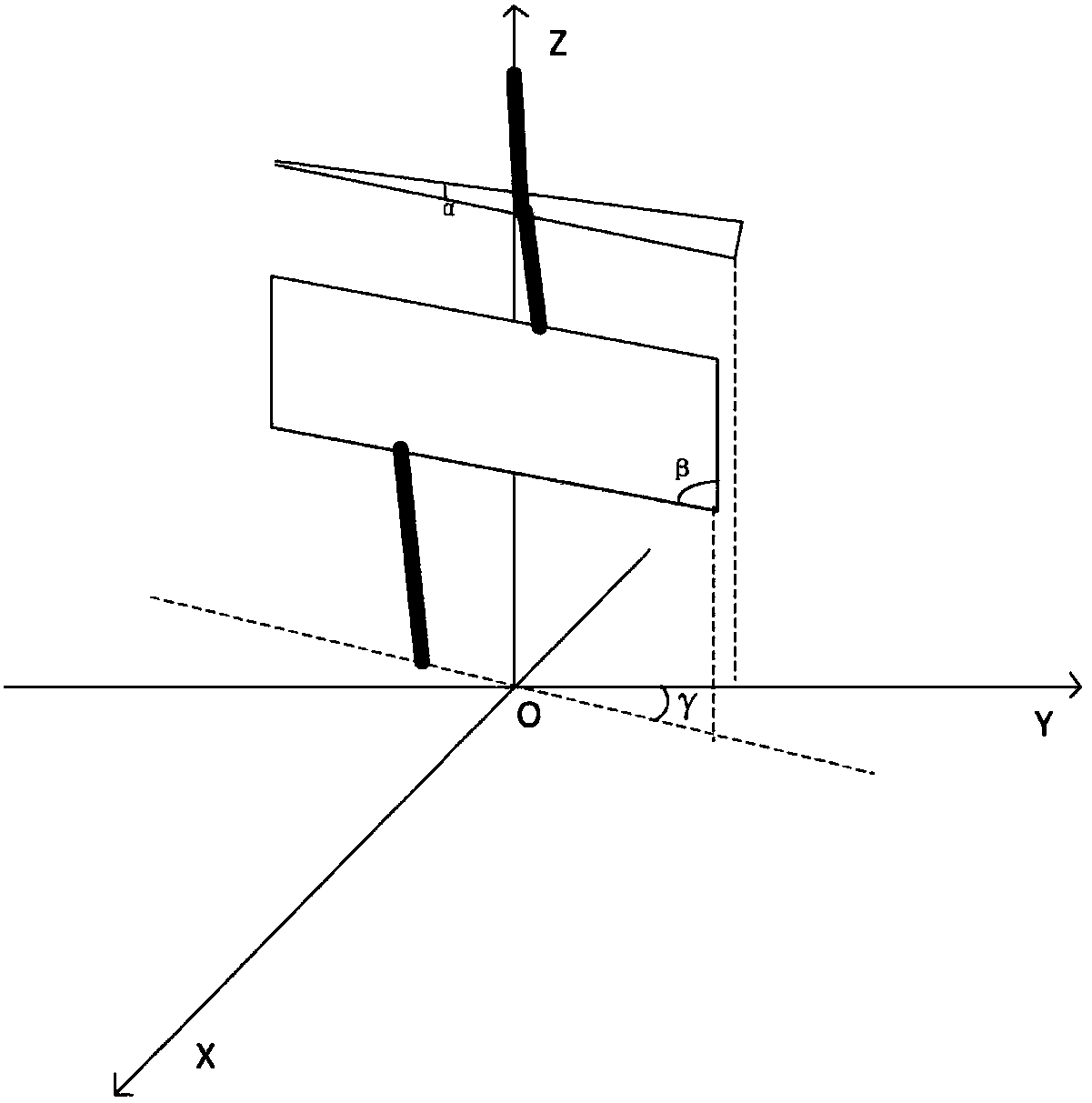

[0061] According to an embodiment of the present invention, a prism-type beam scanning device for laser microhole processing is provided. The beam scanning device is connected to an external control system. The beam scanning device includes: a first special-shaped optical wedge, a second special-shaped optical wedge , the first rotary drive member, the second rotary drive member;

[0062] The first profiled optical wedge includes a first optical wedge portion with an angle α and a first parallel plate portion with an inclination angle β. For the convenience of description, the optical path is described by separating the two parts, which are equivalent to a first optical wedge part with an angle α and a first parallel plate part with an inclination angle β. The surface of the first optical wedge part opposite to the first parallel plate part is the incident surface of the laser light. The laser beam enters the first special-shaped optical wedge from the incident surface and is ...

Embodiment 2

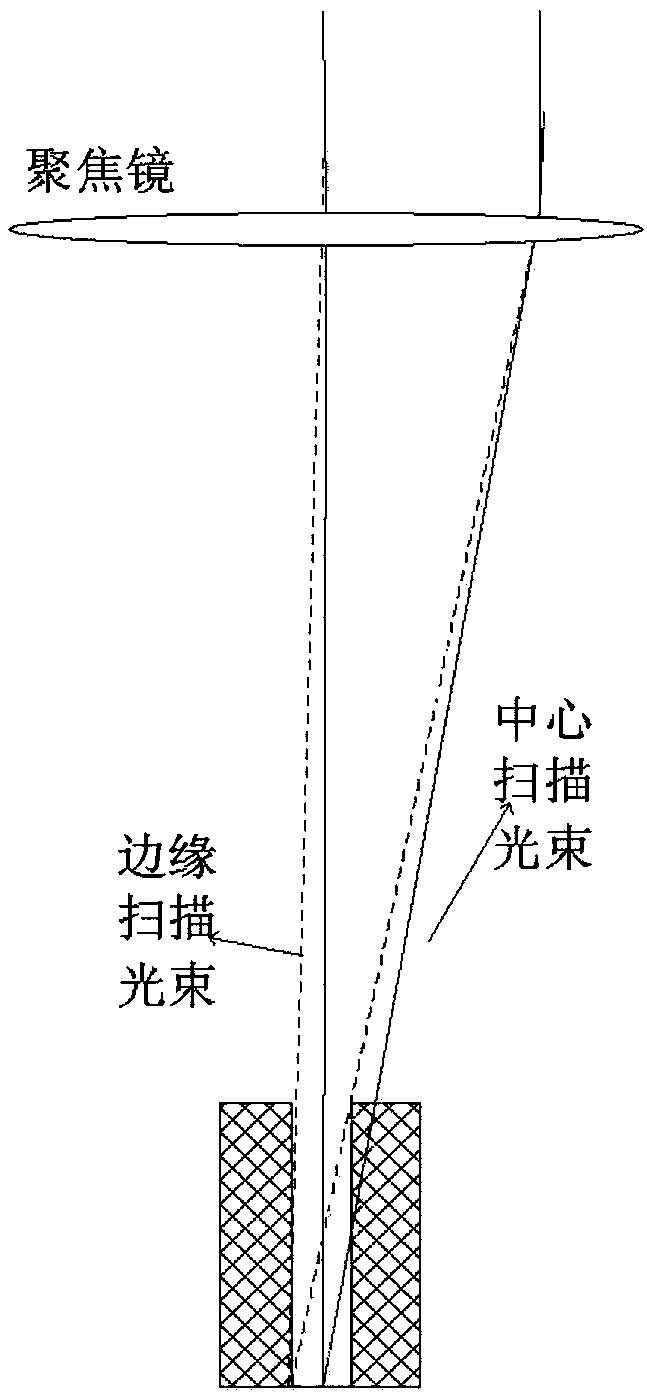

[0068] According to an embodiment of the present invention, a prism beam scanning system for laser microhole machining is provided, including: a laser, a beam expander, a mirror, a two-dimensional beam scanning device, a focusing mirror, a workpiece, and a computer. The computer controls the outgoing beam of the laser. After being collimated by the beam expander, it is reflected by the mirror with a certain installation angle to the two-dimensional beam scanning device to generate an outgoing beam with a certain refraction angle and lateral displacement. Finally, the laser is focused on the workpiece through the focusing mirror. superior. The central line of the light beam reflected by the mirror coincides with the optical axis of the focusing mirror, and the rotation axes of the two special-shaped light wedges in the two-dimensional light beam scanning device are parallel.

[0069] The two-dimensional light beam scanning device is mainly composed of the first special-shaped o...

Embodiment 3

[0082] According to an embodiment of the present invention, a beam scanning method using the above-mentioned beam scanning system is provided. Before using the two-dimensional beam scanning device, the relative positional relationship between two special-shaped optical wedges is first calibrated, and the rotation amount of the driving motor and the The relationship of the initial position for precise control. Build a platform such as Figure 8 As shown: First, a laser beam is emitted from the laser. The laser energy should not be too large, so as not to damage the CCD camera. It is reflected into the beam scanning device by the mirror, and the angle of the mirror is adjusted so that the center line of the beam is in line with the rotation axis of the beam scanning device. Try to coincide; the beam emitted from the beam scanning device is focused by the focusing mirror and then imaged into the CCD camera, where the CCD camera is located at the focal plane of the focusing mirror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com