Diatom ooze capable of degrading formaldehyde

A diatom mud and formaldehyde technology, applied in the field of diatom mud, can solve the problem that diatom mud cannot really and effectively decompose formaldehyde, and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

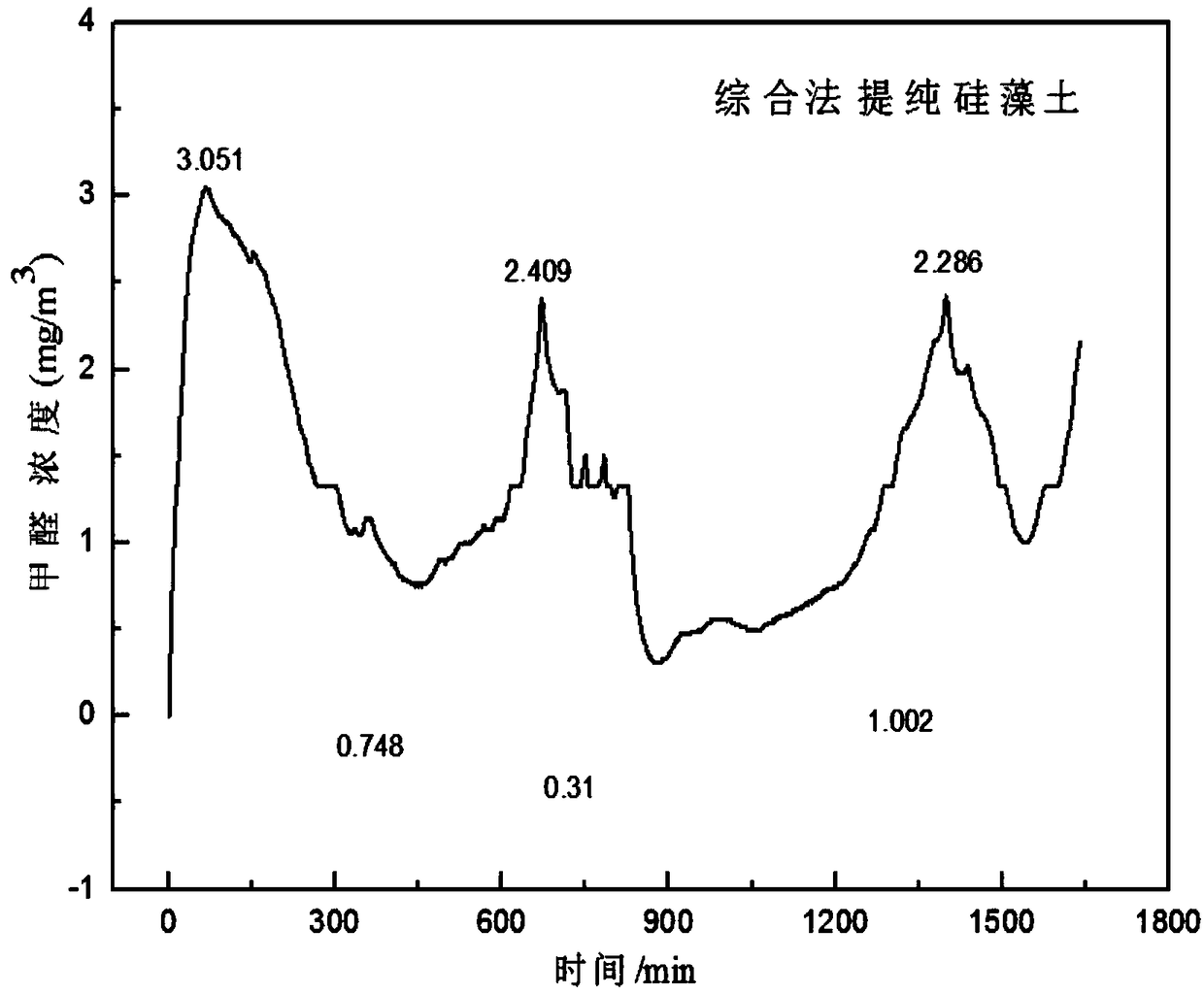

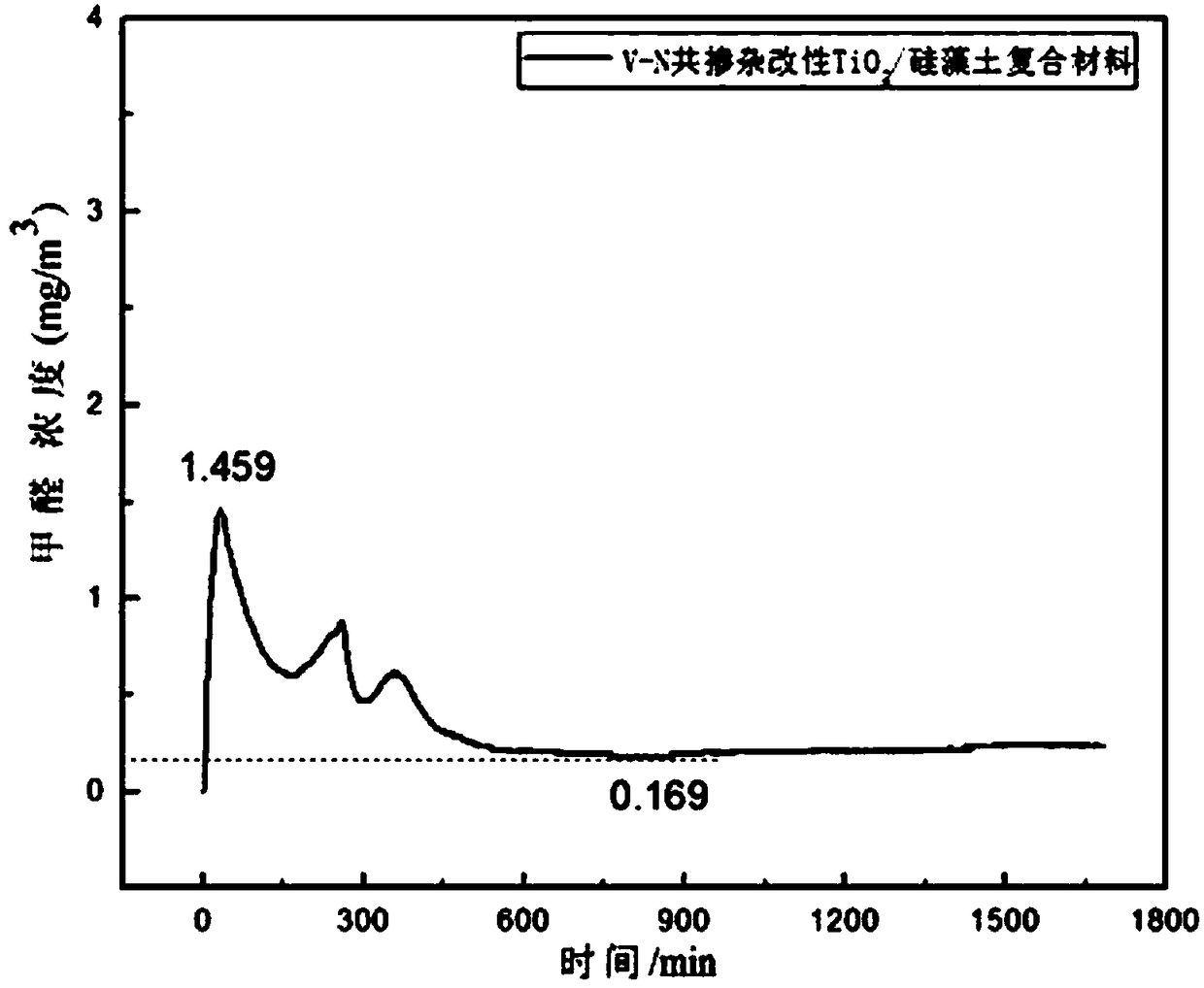

Image

Examples

specific Embodiment approach 1

[0024] Embodiment 1: The diatom ooze described in this embodiment is composed of the following components by weight:

[0025] Vanadium nitrogen modified titanium dioxide photocatalyst / diatomite composite diatom powder 45 parts, dispersible rubber powder 3 parts, hydroxypropyl methyl cellulose ether 0.5 parts, Portland cement 4 parts, gray calcium powder 10 parts, attapulgite 10 parts of powder, 15 parts of washed quartz sand, 10 parts of talcum powder, 1 part of plant fiber and 1 part of inorganic pigment.

[0026] The above-mentioned vanadium nitrogen modified titanium dioxide photocatalyst / diatomite composite diatom powder is prepared according to the following steps:

[0027] Step 1) Grind diatomite raw soil, pass through a 240-500-mesh sieve, add a sulfuric acid solution with a concentration of 40%-70%, stir continuously at room temperature for 4-8h, then wash and filter with deionized water, and then use deionized water to filter. Dried in an oven, calcined in a muffle f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com